Table of Contents

- What is M6? The Basics Explained

- M6 Screw Specifications: Size, Pitch, and Dimensions

- Types of M6 Screws and Bolts

- Materials and Grades of M6 Screws

- Common Applications of M6 Screws

- M6 vs. Other Metric and Imperial Sizes

- How to Select the Right M6 Screw for Your Project

- Installation Tips and Tools for M6 Screws

- Frequently Asked Questions About M6 Screws

- Conclusion: Why M6 Matters in Modern Engineering

M6 is a term you might encounter in various fields. It often appears in engineering, construction, and DIY projects. But what exactly does M6 mean?

In simple terms, M6 refers to a metric screw size. The 'M' stands for metric, and the '6' indicates the nominal diameter in millimeters. This makes M6 a standard size in the metric system.

M6 screws are incredibly versatile. They are used in electronics, automotive, and construction industries. Their applications range from assembling furniture to securing machinery.

Understanding M6 is crucial for selecting the right screw for your project. It involves knowing the size, pitch, and dimensions. These factors determine the screw's suitability for specific tasks.

M6 screws come in various materials and grades. This affects their strength and corrosion resistance. Common materials include stainless steel, carbon steel, and brass.

The choice of an M6 screw can impact performance in different environments. For instance, stainless steel offers excellent corrosion resistance. Meanwhile, carbon steel provides high tensile strength.

In this article, we will explore M6 in detail. From its definition to its applications, you'll gain a comprehensive understanding of this essential component.

What is M6? The Basics Explained

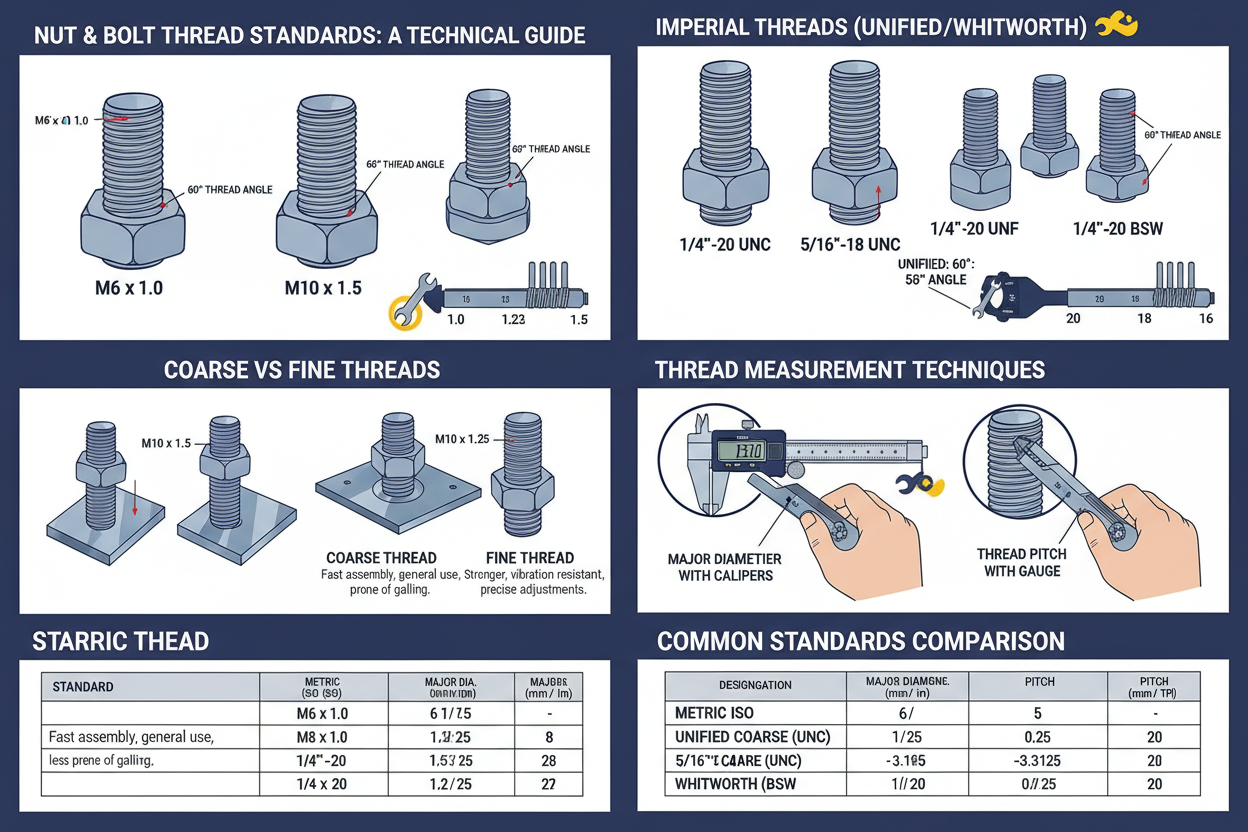

M6 belongs to the metric screw system used worldwide. It follows a logical naming convention. In this system, the 'M' stands for 'metric,' and the number represents the diameter in millimeters.

The number '6' in M6 indicates a 6 mm nominal diameter. This is a standard size, ensuring compatibility. Because of this, M6 screws are widely available and easy to find.

Key Features of M6 Screws:

- Diameter: 6 mm

- Standard Pitch: 1.0 mm

- Range of Lengths: Typically from 6 mm to 100 mm or more

The standard pitch for an M6 screw is 1.0 mm. Pitch refers to the distance between threads. However, M6 screws come in fine pitch variations for specialized applications.

Length is another factor in screw specifications. M6 screws range in length from short to extremely long. This allows them to suit diverse project needs effectively.

Their widespread use is attributed to the ISO metric system. This standardization promotes uniformity, minimizing complications in international projects. This allows for easy interchangeability across borders.

M6 screws are versatile due to their availability in various head types. Flat, pan, and hex heads are among the most common options. Each head type serves different purposes. For example, hex heads are often used where more torque is required.

The choice of head affects how the screw is used. Some heads are designed for countersinking, while others sit on the surface. This versatility allows M6 screws to adapt to various applications efficiently.

Understanding the basic aspects of M6 screws is crucial. It sets the foundation for selecting the right screw for your particular needs. Thus, recognizing their features and applications can lead to better project outcomes.

Back to TopM6 Screw Specifications: Size, Pitch, and Dimensions

When considering M6 screws, it's essential to understand their specifications. These details ensure proper selection and application in various projects. Let's delve into the size, pitch, and dimensions of the M6.

The diameter of an M6 screw measures precisely 6 mm. This metric unit simplifies calculations. It integrates seamlessly into international projects. Alongside the diameter, the pitch plays a significant role in how a screw functions.

An M6 screw typically has a standard pitch of 1.0 mm. This is the distance between two adjacent threads. However, some applications require fine pitch variations. These options provide additional precision in fastening.

Common Dimensions of M6 Screws Include:

- Diameter: 6 mm

- Standard Pitch: 1.0 mm

- Length Variations: 6 mm to 100 mm or more

The length of the screw is another crucial specification. M6 screws come in varying lengths, from very short to particularly long. This range allows for diverse uses in different materials and thicknesses.

The head type and drive style are part of the specifications. Each head type serves a unique purpose, affecting installation. Common head types include flat, pan, and hex.

Head Types and Their Uses:

| Head Type | Best For |

|---|---|

| Flat Head | Countersunk holes |

| Pan Head | Surface-level applications |

| Hex Head | Applications needing extra torque |

Material composition is yet another key aspect. M6 screws come in various materials like stainless steel, carbon steel, and brass. Material choice affects both strength and resistance to corrosion.

The choice of material and thread type has real-life implications. For example, stainless steel offers excellent corrosion resistance. This makes it ideal for outdoor or humid environments.

Finally, understanding these specifications helps in selecting the right M6 screw. This knowledge can lead to successful project outcomes. It also aids in avoiding mismatches that could compromise the structure.

Whether assembling furniture or securing machinery, knowing the M6 screw specs is essential. It ensures that you choose the right screw for your application. With this understanding, tasks become easier and more efficient.

Back to TopTypes of M6 Screws and Bolts

M6 screws and bolts come in various types. Each type serves distinct purposes and meets different needs. Understanding these types can enhance your project efficiency.

The head type significantly impacts the functionality of M6 screws. Various head designs are available, each tailored for specific applications. Let's explore some common head types.

Common M6 Screw Head Types:

- Flat Head: Best for seamless, flush installations

- Round Head: Provides a decorative finish, used when countersinking isn't needed

- Hex Head: Allows more torque, ideal for heavy-duty applications

Another variable is the thread type. M6 screws can have coarse or fine threads. Each is better suited for different materials and fastening requirements.

M6 Thread Types:

- Coarse Thread: Easier to align, offers better grip in softer materials

- Fine Thread: Provides more holding power and precision, often used in machinery

Besides screws, M6 bolts are also essential. Like screws, bolts have different head types and thread designs. They offer a sturdy fastening option in construction projects.

Selecting the right type requires understanding the application. The material of the workpiece, the installation environment, and the required strength all influence your choice. For example, a hex head bolt provides superior torque when securing metal components.

In addition, there are specialty M6 types. Some M6 fasteners have unique coatings for added corrosion resistance. Others are treated for higher tensile strength, ideal in demanding environments.

Choosing the appropriate M6 screw or bolt type ensures your project's success. Whether it's fine threading for machine assembly or coarse threading for woodworking, knowing the types helps. It streamlines installation and bolsters structural integrity.

By recognizing the types available, you can make well-informed decisions. It enhances efficiency, prevents issues, and ensures durability in construction and DIY projects alike.

Back to TopMaterials and Grades of M6 Screws

The composition of M6 screws greatly affects their performance. Different materials impart varying qualities, such as strength, corrosion resistance, and appearance. Choosing the right material is crucial for any project.

Stainless steel is one popular option. It offers excellent corrosion resistance and is suitable for both indoor and outdoor use. Plus, its sleek appearance suits many modern designs.

Carbon steel provides substantial strength. It is often used in heavy-duty applications. However, it's more prone to rust than stainless steel, so it may need protective coatings.

Brass is another choice, mainly used for decorative and electrical applications. It offers good corrosion resistance and conductivity. However, brass is softer than steel, limiting its use in high-stress environments.

Common M6 Screw Materials:

- Stainless Steel: Resistant to rust, strong, suitable for exterior use

- Carbon Steel: High strength, best for structural projects with a coating

- Brass: Decorative, conductive, more for light-duty applications

Besides materials, the grade of an M6 screw indicates its tensile strength. Higher grades mean higher strength but often come at a higher price.

For example, Grade 8.8 screws are standard for many commercial uses, balancing strength and cost. Grades like 10.9 and 12.9 offer even greater strength, often used in heavy machinery.

When selecting a grade, consider the load the screw must endure. Over-speccing can lead to unnecessary costs. Conversely, under-speccing may fail.

Coatings and finishes also impact performance. Zinc plating offers enhanced rust resistance. This makes it ideal for outdoor fixtures exposed to moisture.

The right combination of material and grade extends the life of your screws. It ensures they meet specific application demands. For example, using zinc-plated carbon steel could extend service life while maintaining strength for outdoor structures.

Ultimately, understanding the role of materials and grades in M6 screws leads to better project outcomes. Careful selection ensures structural integrity and longevity, no matter the application environment.

Back to TopCommon Applications of M6 Screws

M6 screws are versatile. They hold things together in various fields. Their uses range from simple home projects to complex engineering tasks.

In the electronics industry, M6 screws secure components. Their precision and small size make them ideal for this sector. Electronics often require fasteners that do not disrupt sensitive circuits.

Automotive applications frequently rely on M6 screws. They fasten parts where precision is vital. From securing engine components to body panels, these screws ensure stability and safety.

The construction world also values M6 screws. They are essential in frameworks and structures. Their strength and availability make them favorites in many construction tasks.

Electronics and Automotive Uses:

- Circuit Boards: Secure components without causing interference

- Engine Assemblies: Fasten metal and plastic parts reliably

- Car Panels: Provide a sturdy and easy-to-align fastening solution

In furniture assembly, M6 screws offer easy disassembly. They make modular pieces feasible. This makes transporting furniture less of a hassle, ideal for urban living.

Many DIY projects benefit from M6 screws too. Their ease of use and availability in various sizes suit countless tasks. Whether it's hanging shelves or building a garden structure, these screws do the job.

Construction and Furniture Uses:

- Framing: Hold wooden or metal parts securely

- IKEA-style Furniture: Allow for simple assembly and reassembly

- Shelving: Provide support for heavy items

M6 screws further find their place in the medical field. Devices and equipment require reliable fasteners. The screws contribute to the durability and safety of medical devices.

Thus, the adaptability of M6 screws makes them indispensable. From professional to personal projects, they stand out. When a reliable, strong, fastener is necessary, these screws often emerge as the preferred choice.

For high-quality M6 screws, consider our 304 stainless steel T-bolt collection, which offers excellent corrosion resistance and durability.

Back to TopM6 vs. Other Metric and Imperial Sizes

Understanding how M6 screws compare to other sizes is crucial. It helps in making informed decisions for projects. This knowledge ensures compatibility and efficiency.

Metric screws like M6 are labeled by diameter in millimeters. For instance, M6 has a 6mm diameter. This system offers straightforward sizing, which simplifies international manufacturing.

In contrast, imperial sizes use inches. A common comparable size is the 1/4-inch screw. Its diameter slightly differs from M6, affecting interchangeability.

Key Comparisons:

- M6: 6mm diameter, standard metric size

- 1/4-inch Imperial: Approximately 6.35mm diameter

- Other Metric Sizes: M4 (4mm), M8 (8mm), etc.

M6 screws are vital in global projects. The metric system's universality eases cross-border collaboration. Many countries prefer metric sizing, making M6 screws widely accessible.

When choosing between metric and imperial, consider the context. Metric threads offer precision. Moreover, projects following international standards typically employ metric sizes.

In summary, knowing the differences between metric and imperial is essential. It informs your choice of screws for your specific needs. Such insight minimizes risks of mismatched parts in both professional and DIY projects.

Back to TopHow to Select the Right M6 Screw for Your Project

Selecting the right M6 screw is key to project success. Various factors influence this decision. Understanding these can enhance your outcomes.

Firstly, consider the material. Different materials offer varied strengths and resistances. For example, stainless steel provides excellent corrosion resistance, ideal for outdoor use.

Next, evaluate the environment. If exposure to moisture or chemicals is likely, use corrosion-resistant screws. This will ensure longevity and reliability in harsh conditions.

The head type of the screw also plays a role. Flat heads are suitable for flush surfaces. In contrast, hex heads provide more torque, useful for heavy-duty applications.

Selection Checklist:

- Material: Stainless steel, carbon steel, or brass?

- Environmental Conditions: Dry, wet, or chemical exposure?

- Head Type: Flat, pan, hex, or round?

- Length and Pitch: Appropriate for the task?

- Load Requirements: What is the stress on the screw?

Furthermore, assess the load requirements. Determine the force the screw will endure. This helps avoid mechanical failure.

Finally, consult project specifications if available. They provide guidance on appropriate screw sizes and materials. Additionally, this ensures compliance with design standards.

In conclusion, careful selection of M6 screws is vital. By considering various factors, you can optimize performance. Consequently, this leads to successful and durable projects.

Back to TopInstallation Tips and Tools for M6 Screws

Proper installation of M6 screws ensures reliability and durability. Choosing the right tools is crucial for effective installation. Different tools suit various screw types and head designs.

For hex head screws, consider using a hex key or Allen wrench. These tools provide precision and control. If dealing with a Phillips or flat head, a screwdriver is more appropriate.

Make sure to select the correct tool size. Incorrect sizes can damage the screw head. This might reduce torque efficiency and affect fastening integrity.

Recommended Tools:

- Hex Key: For hex head screws.

- Screwdriver: For Phillips and flathead designs.

- Torque Wrench: Ensures proper tightness.

- Drill: For faster installation.

Before starting, prepare the surface. Ensure it is clean and free from debris. This step helps improve adhesion and prevents slippage.

When installing, apply consistent pressure. Avoid over-tightening to prevent thread stripping. Monitoring torque can also help achieve optimal fastening.

In summary, use the right tools and techniques for M6 screw installation. This contributes to the longevity and strength of your project. Proper preparation and execution ensure secure and effective fastening.

Back to TopFrequently Asked Questions About M6 Screws

What is an M6 Screw?

An M6 screw is a type of metric screw. The 'M' means metric, while '6' represents its diameter in millimeters. It's widely used in various applications due to its standard size.

What Size is an M6 Screw?

An M6 screw has a nominal diameter of 6 mm. The length can vary from short to quite long, depending on the application. It's important to match the screw length to the specific needs of your project.

What is the Standard Pitch for M6 Screws?

The standard pitch for an M6 screw is 1.0 mm. However, fine pitch variations are also available for more delicate applications. Choosing the right pitch affects the fastening strength and precision.

How Can I Identify M6 Screws?

To identify an M6 screw, measure its diameter across the threads. Typically, it will measure close to 6 mm. Compare this with a standard metric ruler for accuracy.

What Materials Are M6 Screws Made From?

M6 screws can be made from various materials, including stainless steel, carbon steel, and brass. Each material has its advantages, such as strength or corrosion resistance. Selection depends on environmental conditions and use cases.

Are There Different Head Types for M6 Screws?

Yes, M6 screws come in different head types, such as flat, pan, and hex. The head type chosen can affect how the screw sits in the surface. It's essential to select the head type that matches your project's requirements.

How Do I Choose the Right M6 Screw?

To choose the right M6 screw, consider factors such as length, material, and head type. Ensure compatibility with other components. Evaluate the environmental conditions where the screw will be used.

What Tools Are Needed for M6 Screw Installation?

Tools vary based on the head type of the M6 screw. Common tools include hex keys, screwdrivers, and torque wrenches. Correct tool usage prevents damage and ensures proper fastening. Selecting the right tool can impact the quality and durability of your installation.

Back to TopConclusion: Why M6 Matters in Modern Engineering

The M6 screw stands as a cornerstone in engineering projects worldwide. Its metric size aligns with international standards, ensuring universal compatibility. This makes it a reliable choice across multiple industries.

Engineers favor the M6 screw for its versatility and adaptability. It fits seamlessly into everything from construction to electronics. Its standardized dimensions simplify the design process and enhance project efficiency.

The range of materials and head types offered for M6 screws expands their utility. From stainless steel to brass, each option suits different needs. Whether combating corrosion or ensuring strength, there's an M6 screw to match.

Ultimately, the importance of the M6 screw lies in its ability to meet diverse demands. It supports precision, safety, and reliability in various settings. As engineering continues to evolve, the M6 screw remains an essential component in innovation.

Back to Top