🔩A2 Stainless Steel Serrated Flange Nuts - Metric M3 to M16 Locking Nuts | HomeDIYer

Secure your assemblies with our premium serrated flange nuts! These innovative flanged nuts combine a built-in washer and locking mechanism in one fastener. The serrated flange face bites into surfaces to prevent loosening from vibration, while the A2-70 stainless steel construction ensures corrosion resistance. Available in 8 metric sizes from M3 to M16, perfect for automotive, machinery, and structural applications.

Vibration-Resistant Design: The serrated teeth on these flange lock nuts dig into mating surfaces, creating a secure grip that resists loosening from vibration, movement, or torque changes. Eliminates the need for separate lock washers!

📊 Complete Size Range for Serrated Flange Nuts

M3

M4

M5

M6

M8

M10

M12

M16

Select your desired metric size when ordering. Photos are for illustration only.

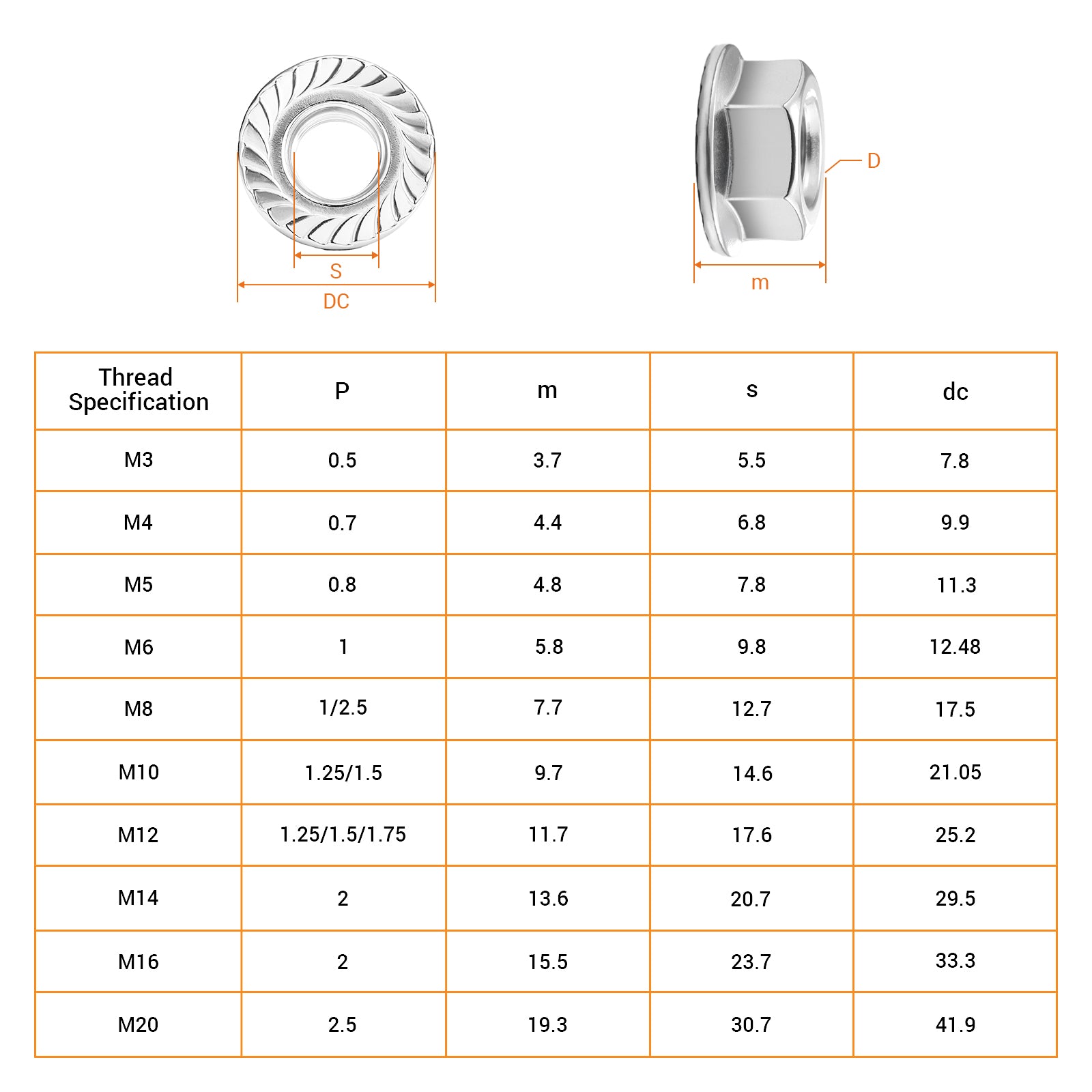

📏 Detailed Specifications for Flange Nuts

| Nut Size |

Thread Pitch |

Wrench Size |

Flange Diameter |

| M3 Flange Nut |

0.5 mm |

5.5 mm |

8 mm |

| M4 Flange Nut |

0.7 mm |

7 mm |

10 mm |

| M5 Flange Nut |

0.8 mm |

8 mm |

12 mm |

| M6 Flange Nut |

1.0 mm |

10 mm |

14 mm |

| M8 Flange Nut |

1.25 mm |

13 mm |

18 mm |

| M10 Flange Nut |

1.5 mm |

17 mm |

22 mm |

| M12 Flange Nut |

1.75 mm |

19 mm |

26 mm |

| M16 Flange Nut |

2.0 mm |

24 mm |

35 mm |

✨ Key Features of A2 Stainless Steel Flange Nuts

-

Built-in Locking Action: The serrated flange face on these serrated flange nuts provides excellent vibration resistance without needing separate lock washers.

-

Integrated Washer: The flange acts as a built-in washer, distributing load over a larger area and protecting surfaces.

-

Corrosion Resistant: Made from A2-70 (304) stainless steel, these stainless steel flange nuts resist rust in outdoor and humid environments.

-

Standard Compliant: Manufactured to DIN6923 standards ensuring precise dimensions and reliable performance.

-

Wide Size Range: Available in 8 metric sizes from small M3 to large M16 metric flange nuts.

-

Time-Saving Design: Combines nut, washer, and locking device in one component for faster assembly.

🔧 Ideal Applications for Serrated Flange Nuts

These versatile locking flange nuts are perfect for:

-

Automotive & Motorsports: Engine mounts, suspension components, and high-vibration areas

-

Machinery & Equipment: Industrial machines, conveyors, and vibrating equipment

-

Structural Applications: Steel frameworks, railings, and bolted connections

-

Outdoor Projects: Fencing, decking, and outdoor furniture exposed to weather

-

Marine Applications: Boat fittings and equipment (with proper stainless grade)

-

DIY & Repair: Any application where vibration loosening is a concern

❓ Frequently Asked Questions (FAQ) About Flange Nuts

Q: How do serrated flange nuts work to prevent loosening?

A: The underside of the flange features small, sharp teeth (serrations). When tightened, these teeth bite into the mating surface (metal, plastic, etc.), creating friction and resistance to rotation. This makes serrated flange nuts highly effective against vibration-induced loosening.

Q: Can I reuse serrated flange nuts?

A: Serrated flange lock nuts are generally designed for single use because the serrations can wear down or become less effective after removal. For critical vibration-resistant applications, it's recommended to use new nuts each time. However, for less critical applications, they may be reused a few times.

Q: Are these flange nuts suitable for use with aluminum or soft materials?

A: Yes! The serrated design actually works very well with softer materials like aluminum, plastic, or wood because the teeth can bite in effectively. However, be mindful not to overtighten as you could damage soft materials. These flange nuts provide excellent grip on both hard and soft surfaces.

Q: What's the difference between DIN6923 and other flange nut standards?

A: DIN6923 is a German industrial standard that specifies dimensions, mechanical properties, and technical requirements for hexagon flange nuts with serrated bearing surface. It ensures consistent quality and compatibility. Other standards include ISO 4161 and various national standards.

Q: Do I need to use a separate washer with these flange nuts?

A: No! That's one of the main advantages of flanged nuts - the integrated flange acts as a built-in washer, distributing load and protecting surfaces. The serrated version adds locking capability, eliminating the need for lock washers too.

Q: Are these metric flange nuts compatible with SAE/Imperial bolts?

A: No, these are metric thread flange nuts designed specifically for metric bolts (M3, M4, M5, M6, M8, M10, M12, M16). They will not properly fit SAE/Imperial bolts (like 1/4", 5/16", etc.). Always match nut and bolt thread types and sizes.