-

That Sinking Feeling: When Your Bolt Vanishes

-

Gear Up: Your Bolt-Sleuthing Toolkit

-

Method 1: The Witness Trick (Ask the Nut!)

-

Method 2: The Paper & Pen Rubbing (Like a Hardware CSI)

-

Method 3: The Thread Impression Trick (Grease or Wax)

-

Method 4: The Bolt Size Finder Lifesaver (Your Ultimate Ally)

-

Method 5: Reverse-Engineering with a Partner Bolt

-

Method 6: Measure the Hole (The Last-Resort Gamble)

-

Decoding Your Findings: Metric vs. Imperial Clues

-

Critical Considerations: Length, Grade & Thread Depth

-

Why Guessing = Disaster (Stripped Threads & Safety Nightmares)

-

FAQs: Solving the Case of the Phantom Bolt

-

Conclusion: Never Lose Sleep Over a Missing Bolt Again!

Forget wandering hardware store aisles, clutching a random nut, hoping for divine intervention. This guide turns you into a bolt-finding detective. We’ll reveal six field-tested methods to identify a missing bolt’s size – from clever tricks using its partner nut or thread impressions, to reverse-engineering with a similar bolt. Crucially, you’ll discover why a dedicated bolt size finder (like our essential thread checker) is the fastest, most foolproof solution when the original bolt is MIA. Learn to decode thread patterns, avoid catastrophic cross-threading, and get back to building – no bolt left behind!

1. That Sinking Feeling: When Your Bolt Vanishes 😫

Let’s be real: losing a critical bolt hurts. It’s not just the cost of a $0.50 fastener. It’s the derailed project, the hours wasted searching, the dread of not knowing what size you even need to replace it.

-

The Hardware Store Nightmare: Walking into Aisle 17, clutching a lonely nut while clerks ask, "What size bolt?" feels like failing a pop quiz.

-

Online Ordering Guesswork: Blindly picking sizes from a dropdown menu? Recipe for returns and delays.

-

The Temptation to "Force It": Desperation leads to trying "close enough" bolts… which always ends in stripped threads or broken parts.

Why this matters: A bolt isn’t just metal. It’s a precision component. Its diameter, thread pitch (threads per inch or distance between them), length, and thread type (UNC, UNF, Metric) must match perfectly. Get it wrong, and you risk:

-

Weakened joints (vibration failure)

-

Stripped threads (costly repairs)

-

Catastrophic failure (on engines, bikes, or structural pieces)

Don’t gamble. Become a bolt detective. Here’s your toolkit.

2. Gear Up: Your Bolt-Sleuthing Toolkit 🧰

Before hunting the phantom bolt, gather these clues:

-

The Partner Nut (If You Have It!): This is your BEST starting clue.

-

Digital Calipers: Essential for precise measurements of nuts, holes, or impressions.

-

Thread Pitch Gauge: Helps identify thread spacing from impressions or partners.

-

Bolt Size Finder / Thread Checker (Your MVP): The ultimate tool when the bolt is gone. A plate with pre-cut threaded holes/posts lets you test nuts or make impressions instantly. [Hint: Like our HomeDIYer Thread Checker – the bolt size finder that never sleeps!]

-

Thin Paper & Pencil: For rubbings.

-

Grease, Modeling Clay, or Soft Wax: For thread impressions.

-

Good Light & Magnifying Glass: Threads are tiny detectives!

-

Marker & Notebook: Document your clues!

Pro Tip: Clean any nuts or threaded holes thoroughly! Gunk hides critical thread details.

3. Method 1: The Witness Trick (Ask the Nut!) 🔩

Scenario: You still have the nut that screwed onto the missing bolt. This witness holds vital clues!

How to Interrogate Your Nut:

-

Identify if it’s Metric or Imperial: Check for markings or measure roughly.

-

Measure Its Inner Diameter (I.D.):

-

Use calipers on the threaded hole. Measure the smallest diameter the threads create (Minor Diameter). Record this (e.g., 0.212 inches, 5.3mm).

-

-

Determine Its Thread Pitch:

-

Option A (Best): Use your bolt size finder (thread checker). Screw the nut onto the checker’s male posts. The post it fits perfectly, revealing the nut’s size (e.g., M6-1.0 or 1/4"-20 UNC). The bolt you need matches this!

-

Option B: Use a thread pitch gauge on the nut’s internal threads. Match the gauge teeth to the threads. Combine pitch with your ID measurement.

-

-

Decode the Size:

-

The nut’s size is the size of the bolt it mates with. A nut labeled M8 fits an M8 bolt. A nut measuring ~0.250" I.D. with 20 TPI fits a 1/4"-20 bolt.

-

Pros: Fast & reliable if you have the nut. Confirms functional fit.

Cons: Requires the nut. Needs calipers or a bolt size finder for accuracy.

4. Method 2: The Paper & Pen Rubbing (Like a Hardware CSI) 📝

Scenario: You have the threaded hole the bolt screwed into, but no nut.

The Forensic Technique:

-

Clean the Threaded Hole: Remove dirt, oil, or debris.

-

Grab Thin Paper & a Soft Pencil: Printer paper works; artist's sketch paper is better. Sharpen that pencil!

-

Make the Rubbing:

-

Place the paper firmly over the threaded hole.

-

Hold it taut.

-

Rub the pencil sideways vigorously over the hole area. Apply even pressure.

-

Goal: Capture the thread pattern imprint on the paper.

-

-

Analyze the Impression:

-

Measure Hole Diameter: Use calipers on the actual hole (not the paper). Get the Minor Diameter.

-

Measure Thread Pitch from Paper:

-

Use your thread pitch gauge blades against the pencil lines on the paper. Find the blade whose teeth perfectly align with the peaks/valleys of your rubbing.

-

Or, measure the distance between several thread peaks on the paper and divide by the number of gaps (for metric pitch).

-

-

-

Combine Clues: Diameter + Pitch = Bolt Size (e.g., Minor Diameter ~5.8mm + Pitch 1.0mm = Likely M6 bolt).

Pros: Low-tech, uses common items. Works on fixed holes.

Cons: Tricky technique. Requires a clean, accessible hole. Accuracy depends on skill.

5. Method 3: The Thread Impression Trick (Grease or Wax) 🧈

Scenario: You need a more physical imprint than paper provides (great for deep or dirty holes).

The Mold Method:

-

Choose Your Medium:

-

Heavy Grease/Lithium Grease: Pack it in firmly.

-

Modeling Clay/Plasticine: Press into a small ball.

-

Paraffin Wax or Candle Wax: Melt slightly, pour carefully (avoid burns!).

-

-

Fill the Hole: Force your medium deep into the threads. Ensure full contact.

-

Extract Carefully: Gently remove the mold. You should see a clear, negative thread impression.

-

Measure the Impression:

-

Diameter: Measure the outer diameter of the male threads on your mold with calipers. This approximates the bolt’s Major Diameter.

-

Pitch: Use your thread pitch gauge directly on the mold’s threads! Find the perfect matching blade.

-

-

Identify the Bolt: Major Diameter + Pitch = Bolt Size (e.g., Major Dia ~8.9mm + Pitch 1.25mm = Likely M8 bolt).

Pros: Creates a physical "positive" model of the bolt threads. The pitch gauge works directly on it.

Cons: Can be messy. Requires care when extracting an intact mold. Wax needs caution.

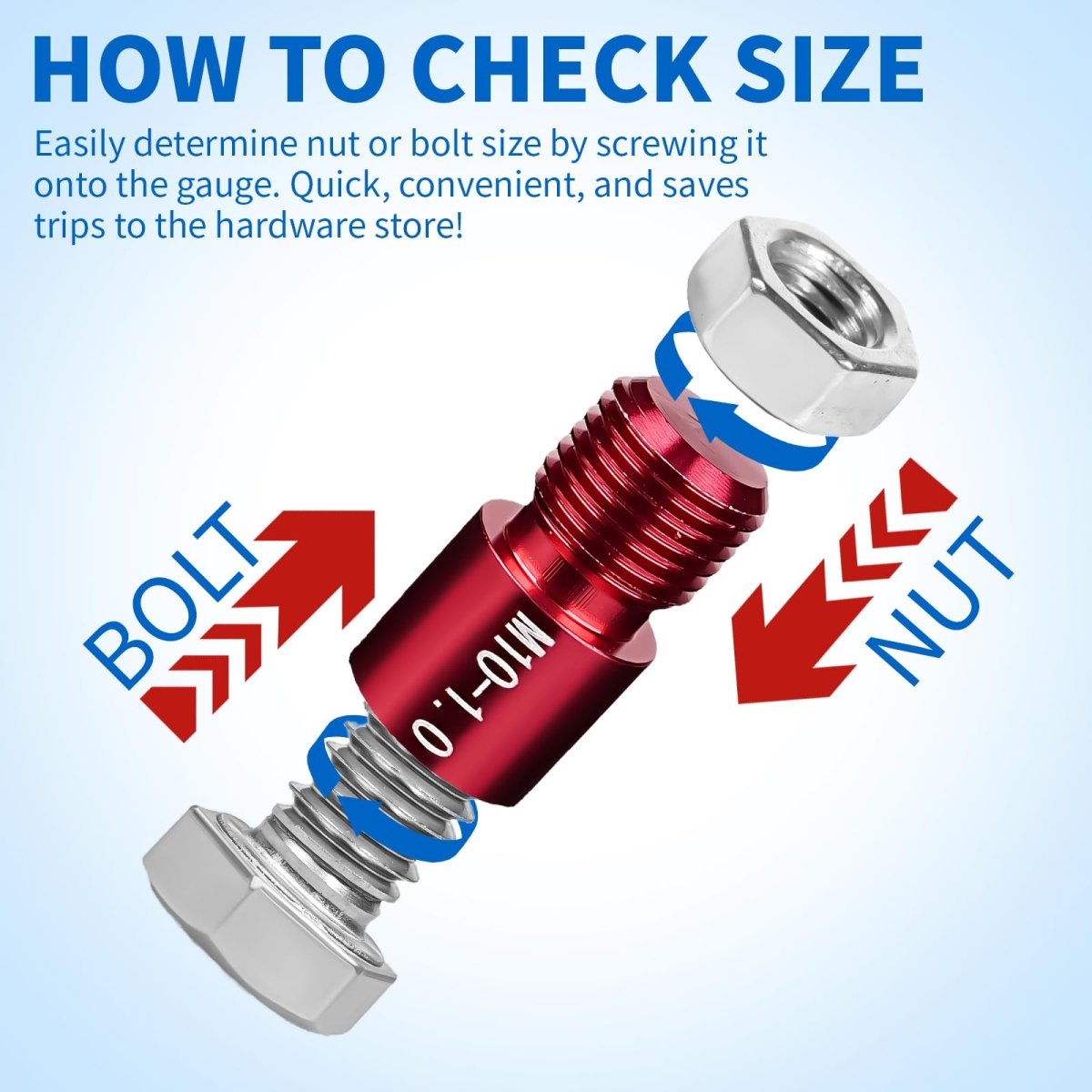

6. Method 4: The Bolt Size Finder Lifesaver (Your Ultimate Ally) ⚡

Scenario: The bolt is gone. You might have the nut, the hole, or nothing but desperation. Enter the hero: a dedicated bolt size finder/thread checker.

Why This is the Smartest Move:

When the original bolt vanishes, a thread checker eliminates guesswork by letting you test functional fit directly:

Using the HomeDIYer Bolt Size Finder:

-

If You Have the Nut:

-

Screw it onto the checker’s male threaded posts.

-

The post it spins onto smoothly reveals its size (e.g., "1/4"-20 UNC). Order that bolt size!

-

-

If You Have the Threaded Hole:

-

Try screwing the checker’s male threaded posts INTO the hole.

-

The post that threads in easily by hand (without forcing!) matches your missing bolt’s size.

-

-

If You Have NOTHING (But Know Location):

-

Identify Likely Sizes: What’s nearby? Engine block? Furniture? Bike frame?

-

Test Common Bolts from Your Checker: Take the plate to the hole. Try likely male posts (e.g., M6, M8, 1/4", 5/16").

-

The Perfect Fit Wins: The post that threads in smoothly is your missing bolt size.

-

Why DIYers Swear By This Bolt Size Finder Method:

-

No Original Bolt Needed: Solves the core problem.

-

Instant Verification: Tests ACTUAL thread engagement – the gold standard.

-

Confirms Diameter AND Pitch AND Type: Eliminates 3 variables at once.

-

Portable Confidence: Fits in your pocket for hardware store trips.

-

Saves Hours: Skip the rubbing, molding, and measuring guesswork.

🛠️ Stop the Guesswork!

"Lost bolts used to ruin my weekend projects. Now I keep my HomeDIYer Thread Checker right on the workbench. Finding replacements takes seconds – even when the original bolt is long gone. It’s the ultimate bolt size finder." - Mark T., DIY Mechanic

Pros: Fastest, most reliable method without the original bolt. Functional test > measurement.

Cons: Requires owning the tool (a wise investment for any serious DIYer).

7. Method 5: Reverse-Engineering with a Partner Bolt 🔄

Scenario: Another bolt from the same assembly or the same part is accessible.

The Clone Approach:

-

Find a Matching Witness: Locate a bolt that screws into the same type of threaded hole or fits the same type of nut as your missing bolt.

-

Measure THIS Bolt:

-

Use calipers to measure its Major Diameter.

-

Use a thread pitch gauge to determine its pitch.

-

(Or instantly ID it with your bolt size finder!).

-

-

Match the Size: Your missing bolt is the same size as this "partner" bolt.

Pros: Simple and accurate if you have a matching bolt.

Cons: Relies on finding an identical bolt. Doesn’t work if all bolts are unique or missing.

8. Method 6: Measure the Hole (The Last-Resort Gamble) ⚠️

Scenario: No nut, no partner bolt, no thread checker. Truly desperate times.

The Risky Procedure:

-

Measure Hole Diameter: Use calipers on the threaded hole's Minor Diameter (the innermost part of the threads).

-

Estimate Major Diameter:

-

For Metric: Add ~0.1-0.2mm to Minor Diameter (e.g., Minor Dia 6.8mm ≈ M8 Bolt).

-

For Imperial: Add ~0.005-0.010 inches (e.g., Minor Dia 0.220" ≈ 1/4" Bolt).

-

-

Guess the Pitch: Based on the application:

-

Coarse threads (UNC, Metric Std) are common for most uses.

-

Fine threads (UNF, Metric Fine) are used in engines, precision gear.

-

-

Buy ONE Test Bolt: Purchase the most likely candidate size. TEST IT CAREFULLY.

MAJOR WARNINGS:

-

Highly Inaccurate: Thread depth varies! Estimation is guesswork.

-

High Risk of Cross-Threading: Forcing the wrong size destroys threads.

-

Avoid on Critical Systems: Never use this on engines, brakes, or structural parts!

Pros: Only requires calipers (and a prayer).

Cons: Extremely unreliable. Potential for costly damage. Use ONLY as a last resort for non-critical items.

9. Decoding Your Findings: Metric vs. Imperial Clues 🧩

Once you have measurements or a confirmed fit:

-

Metric Bolt (e.g., M6 x 1.0):

-

M= Metric -

6= Major Diameter ≈ 6mm -

x 1.0= Pitch = 1.0mm between threads

-

-

Imperial Bolt (e.g., 1/4"-20 UNC):

-

1/4"= Major Diameter ≈ 0.250" -

-20= Threads Per Inch (TPI) -

UNC= Unified National Code (most common)

-

🔍 Critical Insight:

M6 (≈0.236") IS NOT 1/4" (0.250")!

M8 (≈0.315") IS NOT 5/16" (0.3125")!

They’re close but WILL cross-thread. Your bolt size finder prevents this deadly mix-up.

10. Critical Considerations: Length, Grade & Thread Depth 📏

Size isn’t just diameter and pitch!

-

Length: Measure the hole depth! Your new bolt should be:

-

Long enough to engage fully (rule of thumb: Bolt diameter = min thread engagement).

-

Short enough to avoid bottoming out.

-

-

Grade/Strength (Head Markings): Match strength if possible (e.g., Grade 5, 8, or 10.9). Critical for load-bearing applications.

-

Thread Length: Full-thread vs. partial? Measure a partner bolt or the hole’s unthreaded section.

11. Why Guessing = Disaster (Stripped Threads & Safety Nightmares) ☠️

Forcing a "close enough" bolt isn’t resourceful – it’s reckless:

-

Stripped Threads: Ruins the hole, requiring expensive helicoils or replacement parts.

-

Weak Joints: Undersized bolts snap; oversized bolts stretch threads.

-

Vibration Failure: Improper threads loosen and shake apart.

-

Catastrophic Results: On vehicles or machinery, this risk of injury.

🛡️ Your Best Defense: A bolt size finder provides certainty. The $20 tool saves $200 in repairs.

12. FAQs: Solving the Case of the Phantom Bolt ❓

-

Q: Can I use a thread pitch gauge directly on a threaded hole?

-

A: It’s tricky! Use it on a wax impression (Method 3) or a partner nut. Gauges work best on male threads.

-

-

Q: My threaded hole is worn/damaged. Will a bolt size finder still work?

-

A: Possibly not perfectly. Try the best-fitting post on your checker. If threads are stripped, you may need to repair them before replacing the bolt.

-

-

Q: How critical is bolt length?

-

A: Extremely! Too short = weak joint. Too long = bottoming out (false torque). Measure the hole depth or a partner's bolt.

-

-

Q: Does the HomeDIYer Thread Checker include bolt length info?

-

A: No, it identifies diameter, pitch, and type. Length must be measured separately based on your application.

-

-

Q: What if I can’t find ANY match with my bolt size finder?

-

A: It might be a rare thread (like BSW, BSF, or a special pitch). Consult the machinery manuals or a specialist.

-

13. Conclusion: Never Lose Sleep Over a Missing Bolt Again! 💤

Losing a bolt shouldn’t mean losing your weekend. You’re now equipped with detective skills:

-

Leverage the Nut: Your best witness (Method 1).

-

Capture the Threads: Paper rubbings or wax molds (Methods 2 & 3).

-

Embrace the Bolt Size Finder: The fastest, most reliable path to certainty, especially when the bolt is gone (Method 4).

-

Clone a Partner: When available (Method 5).

-

Measure the Hole (Carefully!): Only in true desperation (Method 6).

🔧 Tired of bolt guesswork crippling your projects?

Get instant answers with the HomeDIYer Nut & Bolt Thread Checker – the ultimate bolt size finder for vanished fasteners. Stop searching. Start building.

Got a tricky missing bolt story? Share your detective wins (or fails!) in the comments below! 👇