1. Product core introduction

The 10AWG - 30AWG Silicone Wire from HomeDIYer is a flexible stranded cable with tinned copper conductors, available in white and brown. Designed to meet diverse electrical needs, this product is similar in quality and performance to UL3239 Silicone Wire, with excellent flexibility, heat resistance and durability.

2. The main characteristics of the product

Wide range of AWG sizes: A wide range of sizes from 10AWG to 30AWG are available to meet the diverse current carrying capacity requirements of different electrical equipment. For high power industrial equipment or car starting systems, the 10AWG - 16AWG thick gauge can be used to ensure stable transmission of large currents and avoid overheating of the line; while for some low power electronic equipment, sensors or small appliances, the 24AWG - 30AWG thin gauge can not only satisfy the power requirements, but also provide flexible wiring in limited space, effectively optimizing the design and layout of the electrical system, improving resource utilization efficiency, and ensuring the safety and efficiency of all equipment. It can effectively optimise the design and layout of the electrical system, improve the efficiency of resource utilisation, and at the same time ensure the safe and stable operation of the equipment.

High-quality silicone insulation: the use of high-quality silicone as an insulating material, giving the cable excellent flexibility, so that it can be easily bent, twisted, and convenient in a variety of complex installation environments, whether it is a narrow space within the electronic equipment, or the interior of the car's compact structure, can be easily dealt with, greatly reducing the difficulty of the installation and improve work efficiency. In addition, the silicone insulation also has excellent heat resistance, can maintain stable physical and electrical properties in high temperature environments, effectively preventing aging, deformation or damage to the insulation layer, to ensure the reliability and safety of the cable in the long-term use of the process, to extend the service life of the cable, reduce the frequency of maintenance and replacement.

Advantage of tinned copper conductor: the conductor is made of tinned copper, which not only has good electrical conductivity, can effectively reduce the resistance, reduce the energy loss in the process of power transmission, ensure the efficient transmission of electricity, but also has strong oxidation and corrosion resistance. Tin-plated layer can form a protective film on the surface of the copper conductor, preventing oxidation of copper wires in the humidity, high temperature or chemical corrosive substances in the environment, thus ensuring the long-term stability and reliability of the conductor, maintaining the normal electrical performance of the cable, and providing a solid foundation for the stable operation of the electrical system.

Dual-colour design for easy differentiation: the cable is available in two colours, white and brown, which is convenient for users to differentiate and identify wires with different functions in electrical wiring, for example, white can be used for positive power lines and brown for negative or grounding lines, which makes the wiring clearer, more standardized and easier to identify and manage. This can quickly and accurately locate the required wiring in complex electrical system installation, commissioning, and subsequent maintenance and troubleshooting processes, saving time and effort, improving efficiency and accuracy, and reducing operational errors and potential safety hazards caused by wiring confusion.

3. Product use scene

DIY Electronic Project Production and Repair: When electronic enthusiasts make their own electronic products (such as homemade audio amplifiers, computer power supplies, video game consoles, etc.) as well as repairing and upgrading electronic equipment, the cable's various AWG specifications can meet the requirements of different electronic components for current and signal transmission. Its soft silicone material facilitates fine wiring in the narrow circuit board space, avoiding squeezing or damaging other components; and the two-colour design helps to clearly distinguish between power and signal lines, facilitating the quick construction and debugging of circuits, as well as subsequent troubleshooting and repairing, to ensure the normal operation and performance optimization of the electronic equipment, providing DIY enthusiasts with more creativity and practice space, and enhancing the convenience and efficiency of the maintenance of the electronic equipment. It provides more creative and practical space for DIY enthusiasts and improves the convenience and efficiency of electronic equipment maintenance.

Automotive electrical system modification and upgrading: Automotive audio system upgrading, automotive lighting modification (such as headlights, fog lamps, daytime running lights, etc.), electric seat installation, automotive battery and generator connection and other automotive electrical modification projects require high-quality, high-performance cables to ensure the stability and safety of power transmission. The cable's high-temperature resistance, flexibility, and multiple AWG specifications enable it to adapt to the complex environment of the car's engine compartment and cabin, and to meet the power requirements of different automotive electrical equipment. For example, in car audio modification, suitable AWG specifications can be selected according to the power size of the amplifier, which can be connected to the power supply and speakers of the car through the flexible silicone cable to ensure clear and stable sound quality; in car lighting modification, its good insulation and temperature resistance can ensure the normal operation of the lighting system, improve the lighting effect and safety of the car, and satisfy the owners of the car's personalisation and the pursuit of functionality. Pursuit.

Industrial equipment manufacturing and maintenance: In industrial automated production lines (such as robot control, CNC machine tools, automated packaging equipment, etc.), industrial equipment manufacturing (such as motor drives, electrical control cabinets, industrial heating equipment, etc.), as well as the daily maintenance and repair of industrial equipment, the cable is able to withstand the high temperature, high humidity, strong vibration, electromagnetic interference, and other harsh conditions in the industrial environment. Different AWG specifications of the cable can be used to transmit power supply, control signals and data signals, to meet the strict requirements of industrial equipment for high precision, high reliability and high stability of the electrical connection. The tinned copper conductor's good electrical conductivity and oxidation resistance, as well as the silicone insulation's heat and aging resistance, ensure the cable's long-term stable operation in industrial environments, reduce equipment failures and downtime, improve production efficiency, and provide a strong safeguard for the production and operation of industrial enterprises.

Small commercial and household electrical equipment connection: The reliability and safety of this cable makes it an ideal choice for lighting systems and electrical equipment connection in small commercial premises (e.g. shops, restaurants, offices, etc.), as well as for wiring and installation of all kinds of electrical appliances (e.g. air conditioners, refrigerators, washing machines, electric water heaters, etc.), lighting fixtures, and smart home devices in households. Its various AWG specifications can meet the needs of different power devices, the soft silicone material is convenient for wiring in limited space, the two-colour design is easy for users to differentiate the lines and ensure the specification and safety of the electrical connection, which provides stable power support for commercial operations and family life, ensures the normal use of all kinds of electrical equipment, and improves the convenience and safety of life and work.

4. Product use instructions

Preparation before installation:

Carefully check the appearance of the cable for any defects such as breakage, scratches, flaking insulation, loose strands, oxidation of copper wires, etc. If there are any problems, contact the supplier for replacement in time to ensure that the quality of the cable used is intact. Determine the required cable AWG specifications and colours according to the actual use scenarios and equipment connection requirements, and prepare the necessary installation tools such as wire strippers, crimping pliers, electrician's knife, insulating tape, heat-shrinkable tubing, etc., to ensure that the precision and applicability of the tools, so as to avoid damage to the cable in the installation process.

Wiring and connection:

In the wiring process, the cable should be reasonably planned according to the actual installation path and environmental conditions to avoid excessive bending, twisting or stretching the cable. For the parts that need to be bent, the bending radius should be kept not less than 3 times the outer diameter of the cable (specific multiples can refer to the product specification) to prevent damage to the internal structure of the cable, affecting the electrical performance. At the same time, care should be taken to avoid the cable coming into contact with sharp objects, high temperature parts, humid environment or chemical substances, if it cannot be avoided, corresponding protective measures should be taken, such as using wire troughs, casings or insulating materials for isolation and protection.

When connecting cables and equipment, first use wire strippers to carefully strip the insulation layer at the cable ends, exposing the appropriate length of tinned copper wire (generally according to the requirements of the connection terminals, the length of the exposed length of 3-5 mm or so), and then insert the copper wire into the connection terminals, and use the crimping pliers to firmly press, to ensure that the connection is reliable and has good contact. If a soldered connection is required, suitable solder and soldering techniques should be used to ensure that the solder joints are firm, smooth and free from false soldering. After the connection is completed, the connection is carefully insulated and can be wrapped with insulating tape or heat-shrinkable tubing to prevent leakage and short-circuit accidents.

Precautions for use:

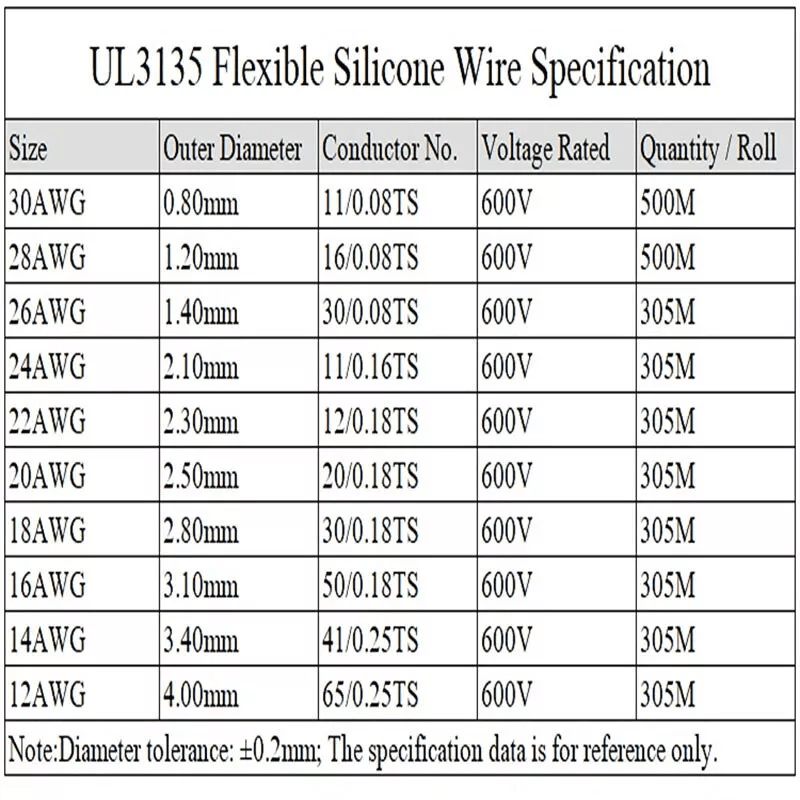

The rated voltage and current of this cable should be used in strict accordance with the parameters on the product specification, and should not exceed the maximum value specified therein, so as not to cause electrical safety accidents, damage to equipment or personal injury. When connecting multiple devices, pay attention to calculating the total power and current to ensure that the cable can withstand the load.

Avoid exposing the cables to harsh environmental conditions such as high temperature, open fire, humidity, corrosive chemicals, etc. If it is unavoidable, corresponding protective measures should be taken, such as the use of fireproof, waterproof, corrosion-resistant wire troughs or casings to protect the cables, in order to prolong the service life of the cables and to ensure the stability of their performance.

Regularly check the connection parts and overall appearance of the cable to see if there is any looseness, oxidation, breakage, etc. If problems are found, they should be repaired or replaced in time to ensure the normal operation and electrical safety of the cable. At the same time, when carrying out equipment maintenance or overhaul, attention should be paid to the protection of cables to avoid damage caused by human factors.