1. Why Bearings Matter in Modern Engineering

Bearings reduce friction and enable smooth rotation in everything from car wheels to factory machinery. The term "bearing meaning" spans multiple applications:

- Automotive: Wheel bearings ensure safe, quiet driving.

- Industrial: Ball bearings handle high-speed machinery.

- DIY: Bearing pullers simplify maintenance tasks.

Key Products Highlighted:

- Wheel Bearings: Critical for vehicle safety and performance.

- Ball Bearings: Versatile solutions for motors and tools.

- Bearing Pullers: Essential for removing worn bearings.

2. Wheel Bearings: The Backbone of Vehicle Safety

Wheel bearings (49,500 monthly searches) are vital for smooth rides. Signs of a bad wheel bearing include grinding noises and uneven tire wear.

Maintenance Tips:

- Check Noise: A humming or grinding wheel bearing noise indicates wear.

- Lubrication: Use wheel bearing grease to extend lifespan.

- Replacement: Follow our "how to replace wheel bearing" guide or consult a pro.

Pro Tip: Pair with a hub bearing assembly for easier installation.

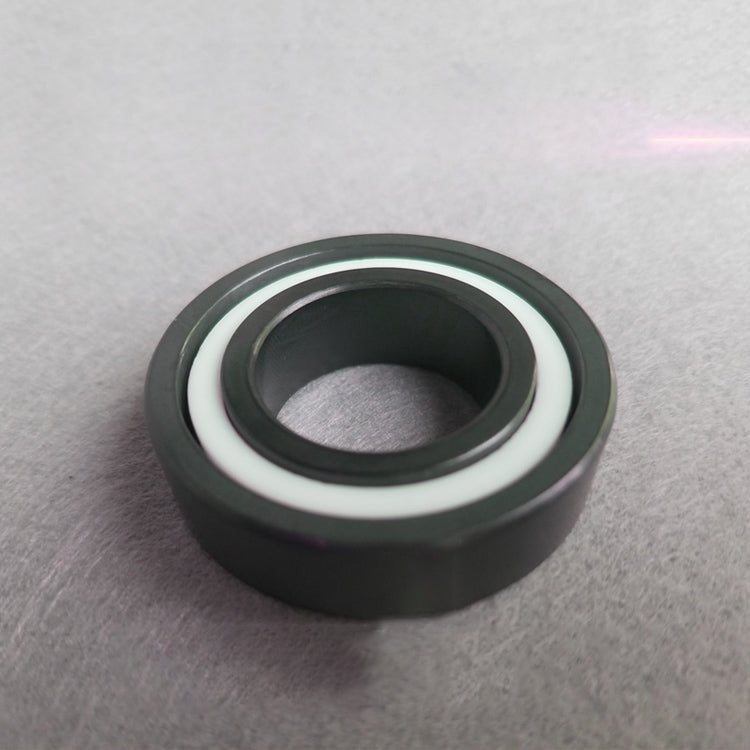

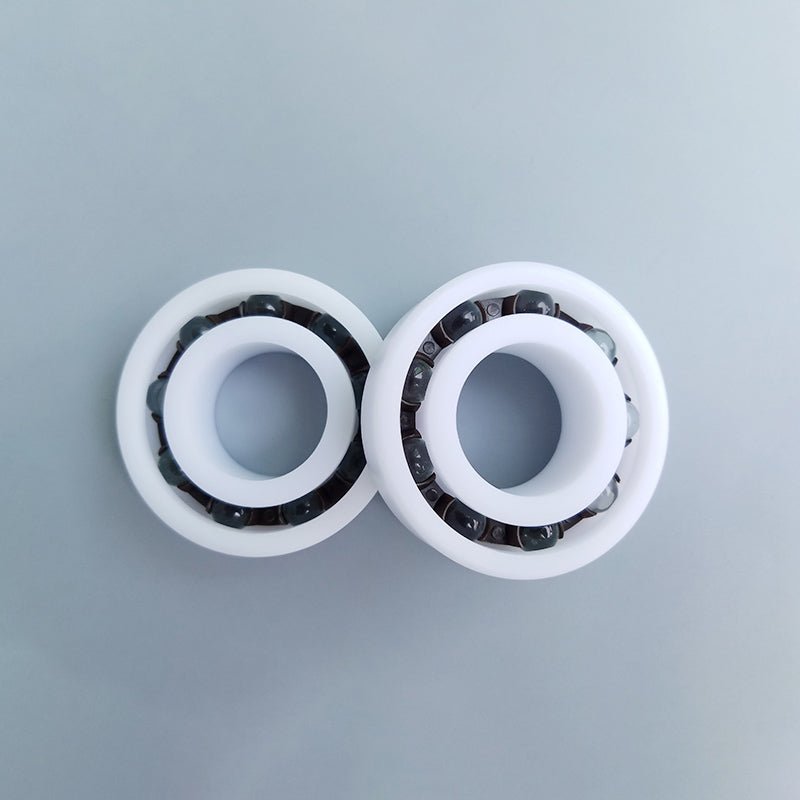

3. Ball Bearings: Precision for Industrial and DIY Use

Ball bearings (9,900 searches/month) minimize friction in rotating parts. Common uses include:

- Electric Motors: Ensure efficient power transfer.

- Skateboards/Scooters: Provide smooth rides.

- 3D Printers: Enhance precision in moving parts.

Trending Product: Explore our 608 bearings for small-scale projects.

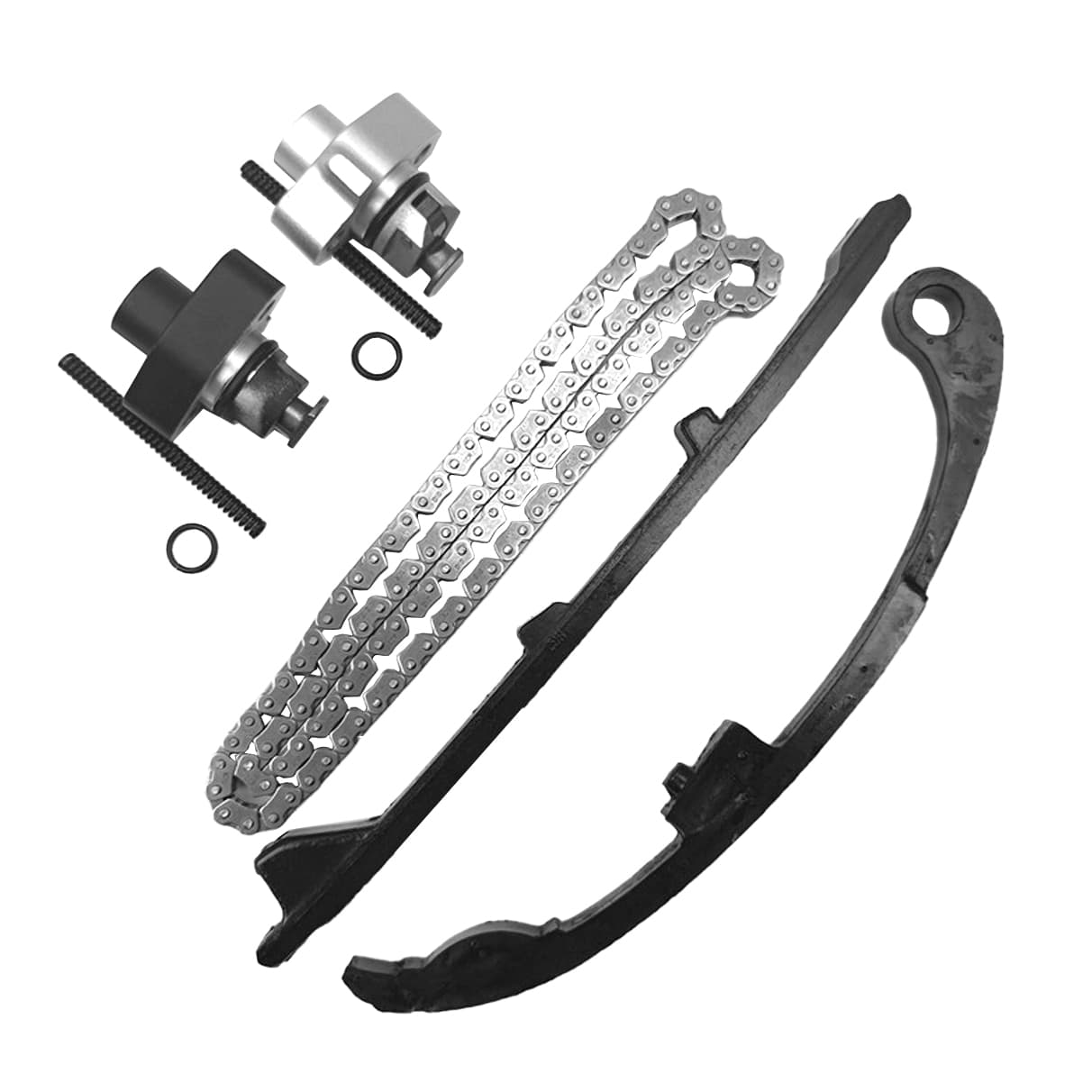

4. Bearing Pullers: Your DIY Best Friend

Bearing pullers (12,100 searches/month) are must-haves for mechanics. Use them to:

- Remove stuck bearings without damaging shafts.

- Install new bearings with a bearing press kit.

- Save time on wheel bearing replacement tasks.

Did You Know? A harbor freight bearing puller is a budget-friendly option for hobbyists.

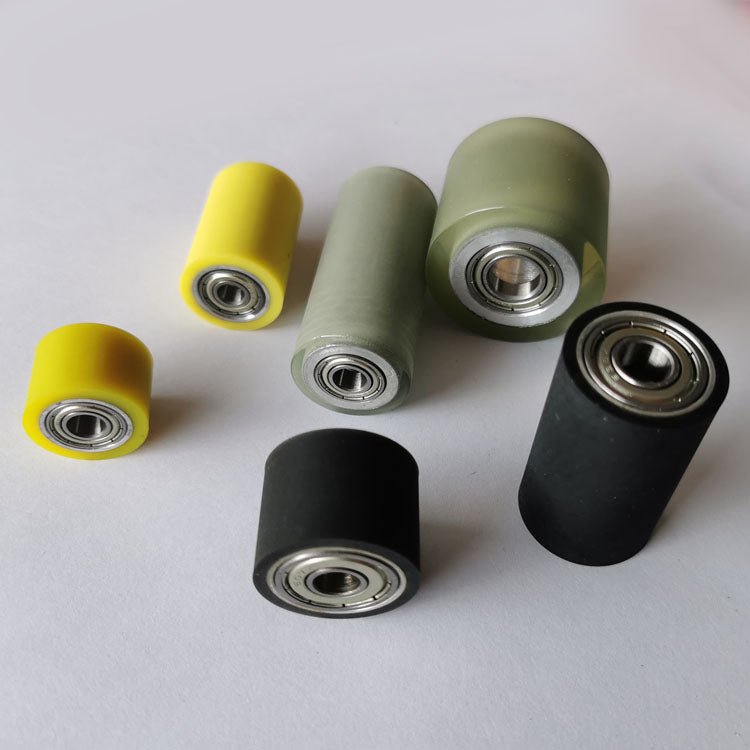

5. Industrial Solutions: Heavy-Duty Bearings

For factories and construction, heavy-duty bearings like pillow block bearings (4,400 searches/month) and tapered roller bearings (1,900 searches/month) handle extreme loads.

Applications:

- Conveyor Belts: Use linear bearings for smooth movement.

- Agriculture: Thrust bearings support heavy machinery.

- HVAC Systems: Blower motor bearings ensure airflow efficiency.

6. How to Diagnose Bearing Issues

- Listen: Grinding or squealing sounds signal a bad wheel bearing.

- Inspect: Check for play in hub bearings by shaking the wheel.

- Test: Use a bearing press to assess tightness.

Warning: Ignoring wheel bearing symptoms can lead to wheel detachment!

7. Top Products at HomeDIYer

- ProSeries Wheel Bearing Kit: Includes grease, seals, and a 5-year warranty.

- Industrial Ball Bearing Pack: Stainless steel for corrosion resistance.

- Heavy-Duty Bearing Puller Set: For automotive and machinery repairs.

Customer Favorite: Timken Bearings for unmatched durability.

8. Step-by-Step: Replacing a Wheel Bearing

- Lift the Vehicle: Secure with jack stands.

- Remove the Hub: Use a wheel bearing puller.

- Install New Bearing: Press in with a bearing press tool.

- Reassemble: Apply bearing grease and test drive.

Tools Needed: Bearing puller, torque wrench, grease gun.

9. FAQs

Q: How much does a wheel bearing replacement cost?

A: Typically 150–150–400, depending on labor and parts.

Q: Can I reuse old bearings?

A: No—always replace worn bearings to avoid safety risks.

Q: What’s the difference between ball and roller bearings?

A: Ball bearings handle radial loads; roller bearings manage heavier axial loads.

10. Why Choose HomeDIYer?

- Free Shipping: On orders over $75.

- Expert Support: Chat with our bearing specialists 24/7.

- Lifetime Warranty: On all industrial-grade bearings.

Final Thoughts

Whether you’re tackling a wheel bearing hub assembly replacement or sourcing ball bearings for a robotics project, HomeDIYer delivers precision and reliability. Explore our collection today and keep your machines running smoothly!

CTA: Shop Bearings & Tools → https://homediyer.com/collections/bearings