1. Why Proper Lubrication Matters

Grease fittings (commonly called zerk fittings) prevent costly bearing failures in automotive, industrial, and agricultural equipment. A single clogged grease fitting can cause:

- 47% increase in joint wear (SAE Journal study)

- 80% shorter component lifespan

Our stainless steel grease fittings resist corrosion in harsh environments.

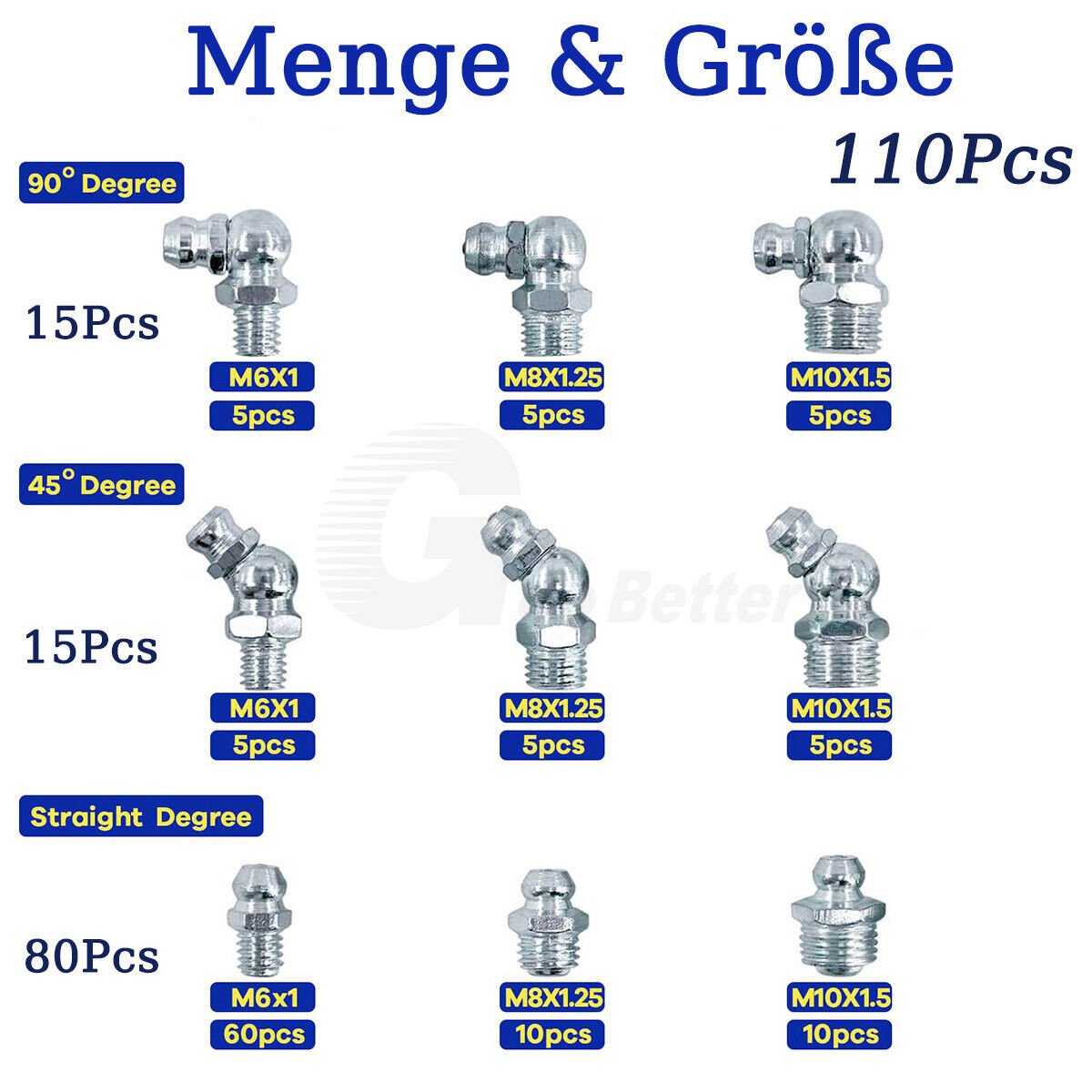

2. Grease Fitting Types Explained

TypeBest ForHomeDIYer PicksStandard ZerkGeneral use1/4" grease fittingwith 10K PSI rating90-Degree AngledTight spacesLow-profileflush grease fittingButton HeadHigh-impact zonesCNC-milledbutton head grease fittingNeedle TipPrecision lubricationneedle grease fittingfor ball jointsMetric ThreadImported machinery6mm/8mm grease fittingkits

Pro Tip: For ball joint grease fittings, use our needle-type adapters to prevent seal damage during lubrication.

3. Size & Thread Compatibility Guide

- SAE Sizes: 1/4 grease fitting (most common), 1/8 npt grease fitting, 3/8 grease fitting

- Metric Sizes: 6mm grease fitting, 8mm grease fitting, M6x1 threads

- Thread Kits: Our grease fitting tap kit includes 8 sizes for DIY port creation

Download our free grease fitting size chart PDF for cross-reference.

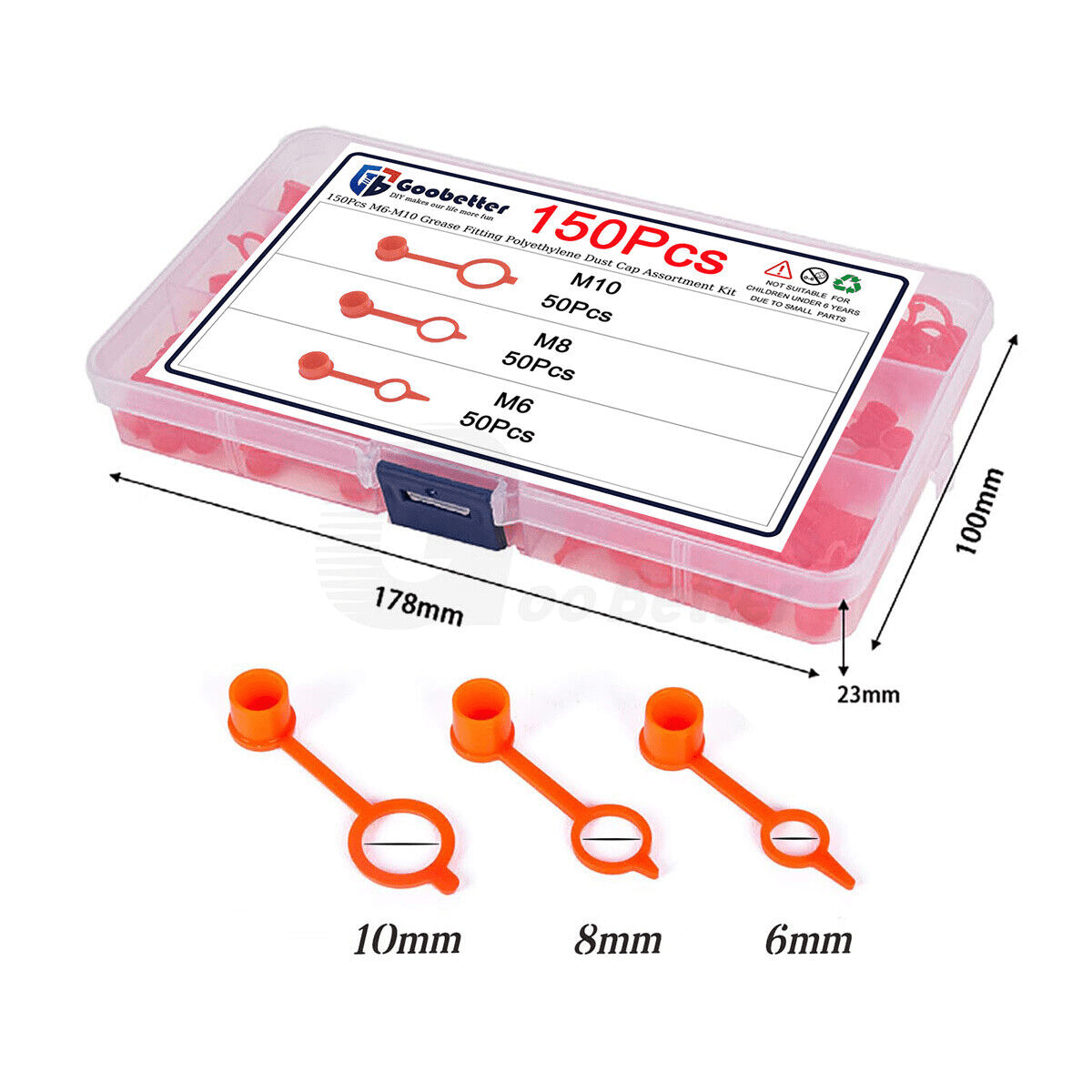

4. Essential Accessories

- Cleaning Tools: Zerk grease fitting cleaner to unclog hardened grease

- Protection: Grease fitting caps prevent dirt ingress

- Extensions: 90 degree grease gun fitting for hard-to-reach areas

- Adapters: Grease fitting adapter kit for incompatible nozzles

Case Study: A farm equipment operator reduced maintenance time 65% using our remote grease fitting kit.

5. Step-by-Step Maintenance

"How to grease a zerk fitting without mess?"

- Clean: Use zerk grease fitting cleaning tool to remove debris

- Attach: Secure grease gun fitting squarely

- Pump: Inject until fresh grease emerges (avg. 3-5 pumps)

- Cap: Install grease fitting covers to prevent contamination

Warning: Over-greasing damages seals! See our video guide for u joint grease fitting servicing.

6. Troubleshooting Common Issues

- Clogged Fittings: Use grease fitting rejuvenator + heat gun

- Stripped Threads: Retap with grease fitting tap size tools

- Leaks: Replace with self-tapping grease fittings

- Broken Fittings: Extract with grease fitting removal tool

7. Industry-Specific Solutions

- Automotive: Ball joint grease fittings with 45° adapters

- Agriculture: Track tensioner grease fittings for excavators

- DIY Home: Flush type grease fitting for lawnmower decks

8. Why HomeDIYer Wins

- Lifetime Guarantee: All button head grease fittings

- Free Shipping: Orders >$59 (continental US)

- Expert Support: Send photos of your grease fitting thread size challenges for custom solutions