The Complete Guide to Brass Fittings: Types, Sizing, and Installation Mastery

Brass fittings are the unsung backbone of fluid systems. From household plumbing to industrial hydraulics, these corrosion-resistant connectors prevent leaks while withstanding high pressure and temperature extremes. At HomeDIYer, we stock over 200 brass fitting types – each machined to exacting standards. This guide will transform you from novice to expert in selecting, installing, and maintaining brass fittings.

Section 1: Why Brass Reigns Supreme

Brass (copper-zinc alloy) outperforms plastic and steel with:

- Corrosion resistance: Withstands water, chemicals, and weather (ideal for brass hose fittings).

- Malleability: Easily tightened without cracking (critical for brass compression fittings).

- Temperature tolerance: Handles -200°F to 400°F (perfect for HVAC systems).

- Lead-free options: Certified safe for potable water (look for NSF-61 stamps).

Section 2: Brass Fitting Types Explained

Match fittings to your project:

- Compression Fittings:

Create seal via ferrule compression (e.g., 1/4 brass compression fitting). Use with soft copper or plastic tubing. - Tee & Cross Fittings:

Split flow directions (e.g., brass tee fitting 1/2). Essential for irrigation systems. - Bulkhead Fittings:

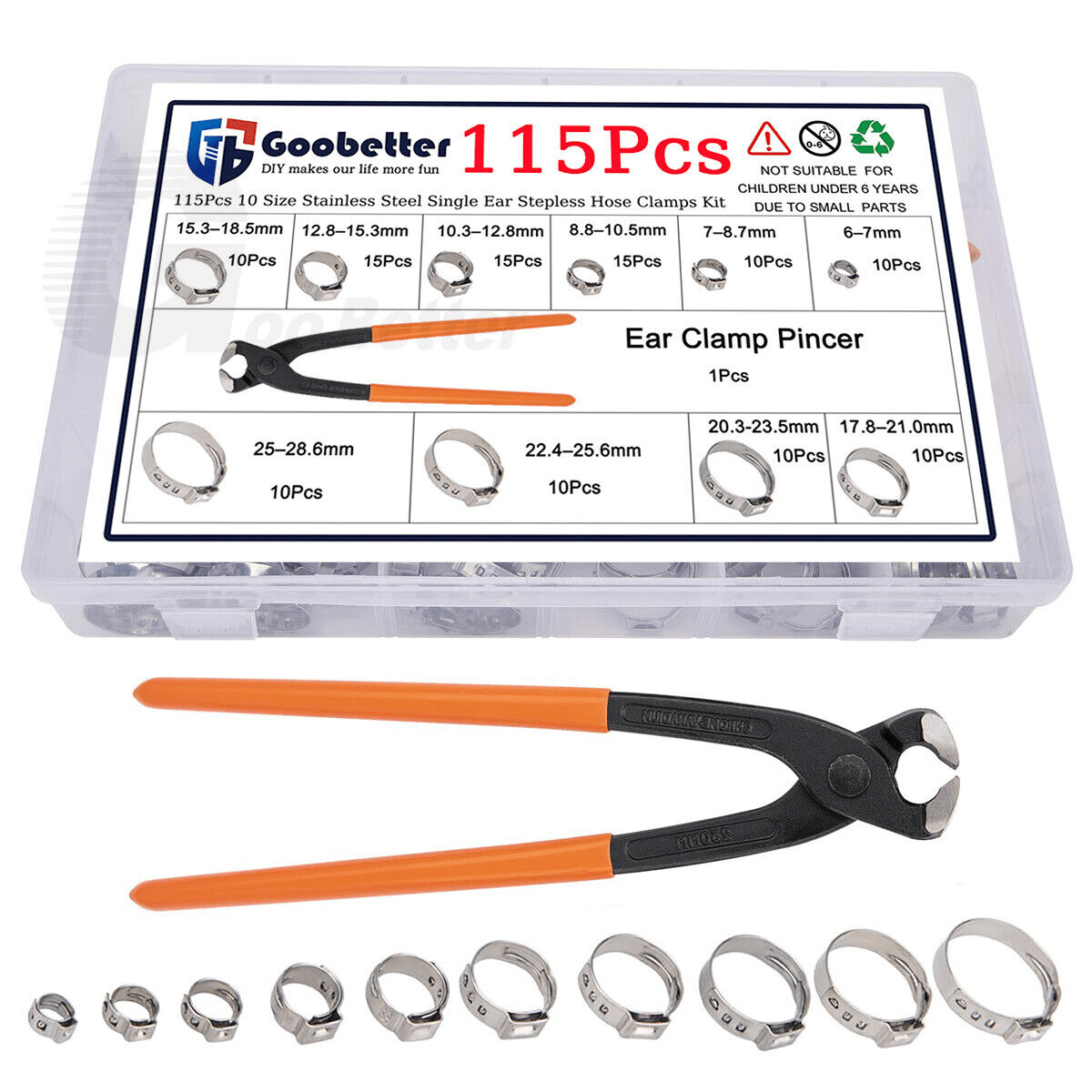

Seal-tight tank penetrations (e.g., brass bulkhead fitting). Perfect for water storage tanks. - Barbed Fittings:

Hose clamps secure tubing (e.g., brass barbed fitting). Ideal for low-pressure fuel lines. - Union Fittings:

Allow easy disassembly (e.g., brass union fitting). Maintenance-friendly for industrial use.

Section 3: Sizing Demystified

Avoid leaks with proper sizing:

- NPT vs. BSP: NPT (US) has 60° threads; BSP (UK/EU) uses 55° threads. Never interchange!

- Key Dimensions:

- Pro Tip: Print our free brass fitting size chart – match threads visually.

Section 4: Material Compatibility Guide

Connect safely between materials:

- Brass-to-PVC: Use threaded adapters (e.g., brass to pvc fitting). Apply Teflon tape on male threads.

- Brass-to-Copper: Solder or flare fittings (e.g., brass to copper fitting). Avoid galvanic corrosion with dielectric unions.

- Brass-to-PEX: Use crimp or clamp rings (e.g., brass to pex fitting). Ensure PEX rating matches temperature.

Section 5: Step-by-Step Installation

Tools Needed: Two wrenches, Teflon tape, pipe cutter.

- Cut tubing squarely and deburr edges (prevents ferrule damage).

- Wrap male threads clockwise with 3 Teflon tape layers (except compression fittings).

- Hand-tighten first, then use wrenches:

- Pressure test at 1.5x operating PSI for 15 minutes.

Section 6: Troubleshooting Common Failures

- Leaks at Joints:

Over-tightening distorts ferrules. For brass compression fittings, replace ferrule and re-torque. - Frozen Threads:

Apply heat with a torch (400°F max) to expand brass. Use penetrating oil. - Cracked Fittings:

Caused by incompatible metals or thermal stress. Switch to forged brass union fittings.

Section 7: Industrial vs. DIY Applications

- Home Projects:

Use brass hose fittings for washing machines, brass t fittings for garden irrigation. - Industrial Uses:

Choose forged bulkhead pipe fitting brass for chemical tanks or pneumatic brass fittings for air compressors.

Section 8: Why HomeDIYer Fittings Outlast

Our brass fittings feature:

- Military-grade brass: C36000 alloy with 15% zinc for optimal strength.

- Triple-polished finish: Resists oxidation and mineral buildup.

- Lifetime warranty: Free replacements for manufacturing defects.

Conclusion

Whether you're repairing a leaky faucet with 1/4 brass fittings or designing a hydraulic system with 3/4 brass compression fittings, HomeDIYer delivers precision-engineered solutions. Explore our catalog with filter-by-size tools and downloadable guides. Join 75,000+ customers who trust us for leak-free connections!