1. Why Concrete Screws Outperform Other Fasteners

Concrete screws are engineered with unique features for rock-solid holds:

- Self-Tapping Design: Threads cut into concrete as you drive them, eliminating the need for plugs or anchors.

- High Shear Strength: Withstand up to 1,000 lbs of force.

- Corrosion Resistance: Stainless steel concrete screws and blue concrete screws (with corrosion-resistant coating) survive humidity, salt, and weather.

Pro Tip: Search for “concrete screws vs anchors” to see why screws win for heavy-duty applications.

2. Types of Concrete Screws: Match Your Project

Self-Tapping Concrete Screws

Ideal for quick installations in soft concrete or block. No pilot hole needed! Use keywords like “concrete screws no pre drilling” to find them.

Anchor Screws for Concrete

Designed for overhead or seismic zones. Pair with concrete anchors and screws for critical structural work.

Masonry Concrete Screws

Short, aggressive threads for brick and block. Perfect for “screws for concrete walls” or “concrete block screws”.

Specialty Screws

- Wood-to-Concrete Screws: Coarse threads bite wood while tips penetrate concrete.

- Small Concrete Screws: For delicate tasks like securing “concrete screws for TV mount”.

3. Key Features to Consider

- Material: Choose stainless steel for outdoor use or galvanized for indoor projects.

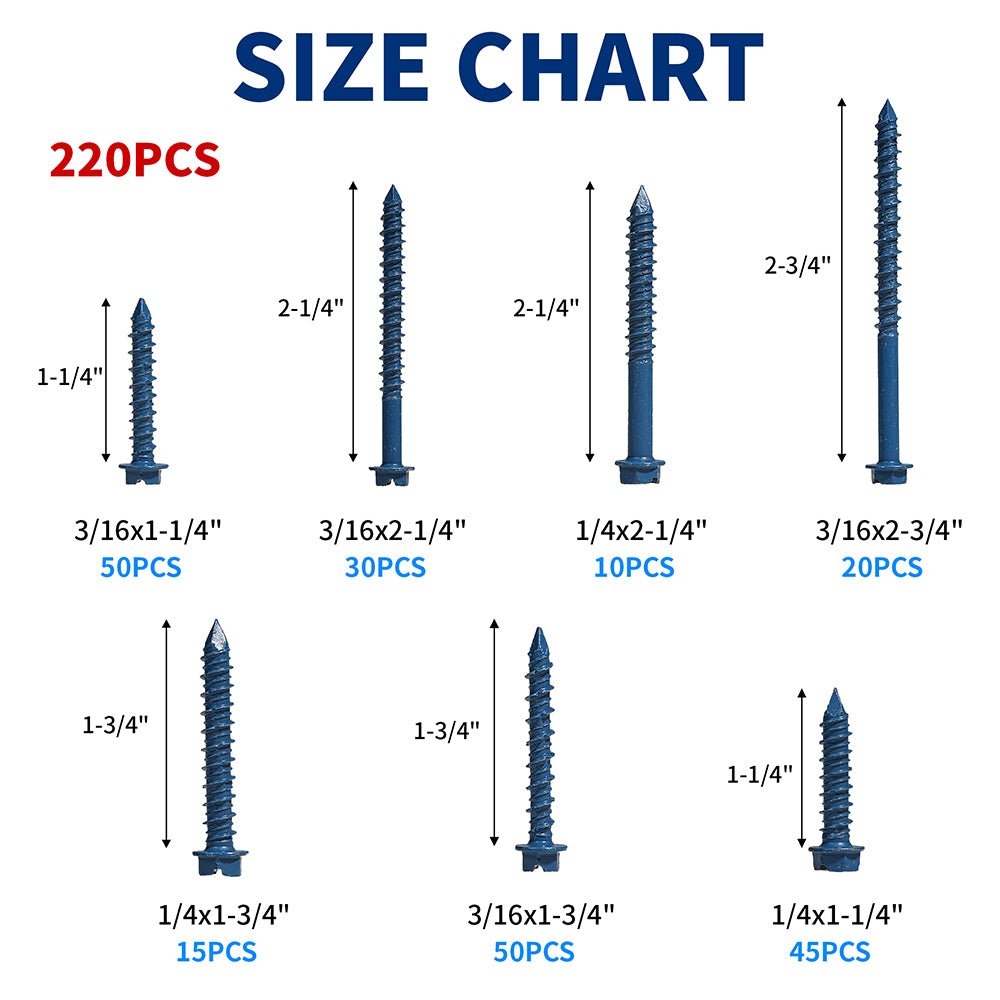

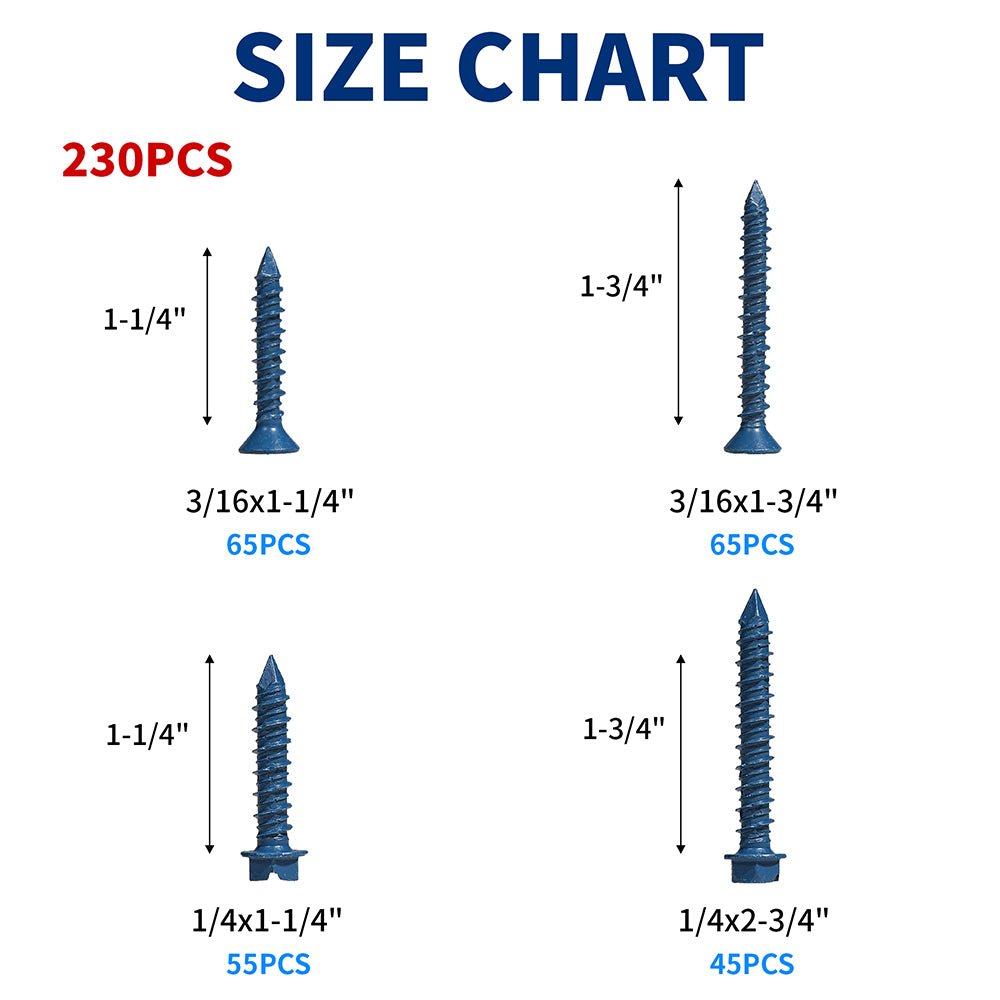

- Size: 1/4 concrete screws handle light loads; 3/8 concrete screws support heavy fixtures.

- Head Type: Hex heads for torque; flat heads for flush finishes.

- Coating: Blue concrete screws offer extra corrosion protection.

Popular Searches:

- “best screws for concrete”

- “concrete screws how to install”

4. Step-by-Step Installation Guide

Tools Needed: Hammer drill, carbide-tipped bit, vacuum, safety goggles.

- Drill the Pilot Hole

- Clean the Hole

Blow out dust with compressed air or a vacuum. Debris weakens the hold! - Drive the Screw

Warning: Over-tightening strips threads! Search “how to put screws in concrete” for video demos.

5. Critical Dos and Don’ts

✅ DO:

- Use concrete screws self tapping in pre-cast concrete (softer than poured).

- Choose long concrete screws (4-6") for load-bearing walls.

- Seal holes in wet areas with silicone to prevent corrosion.

❌ DON’T:

- Reuse screws—threads wear out after one installation.

- Use regular screws in concrete—they’ll snap or pull out.

- Skip safety gear. Concrete dust is hazardous!

6. Troubleshooting Common Issues

Problem: Screw spins but won’t tighten.

Fix: The hole is too wide. Fill with epoxy, let cure, then re-drill.

Problem: Rust stains on stainless steel concrete screws.

Fix: You likely used low-grade stainless. Upgrade to 304/316-grade screws. Search “will stainless steel concrete screws rust” for comparisons.

Problem: Screw head strips.

Fix: Use impact drivers, not standard drills, for high-torque jobs.

7. Top Applications for Concrete Screws

- Outdoor: Secure wood to concrete screws for decks, pergolas, and fences.

- Home Interiors: Mount TVs with “concrete screws for TV mount” (min. 1/4" diameter).

- Plumbing: Attach toilet flanges with “concrete screws for toilet flange”.

- Structural: Anchor beams using concrete lag screws.

8. Frequently Asked Questions

Q: Do I need to pre-drill for concrete screws?

A: Only for non-self-tapping types. Search “self drilling concrete screws” for no-drill options.

Q: How much weight can concrete screws hold?

A: A single 3/8" screw supports 200+ lbs in concrete. Use multiple screws for heavy items.

Q: Can I use concrete screws in brick?

A: Yes! Opt for “masonry concrete screws” with shallower threads.

9. Why HomeDIYer Screws Stand Out

- No-Skip Threads: Precision-cut grooves prevent pullouts.

- USA-Made Steel: Harder than big-box brands (e.g., Home Depot concrete screws).

- Weatherproof Coatings: Our blue concrete screws outlast standard galvanized by 5x.

- Expert Support: Ask us about “how to use concrete screws” or “best screws for concrete block”!

Conclusion

From anchor screws into concrete for seismic zones to small concrete screws for crafts, HomeDIYer has the right fastener for every job. Our screws are trusted by DIYers and pros for their brute strength, corrosion resistance, and ease of use. Ready to tackle your project? Use keywords like “concrete screws near me” or “concrete screws for sale” to shop our collection!