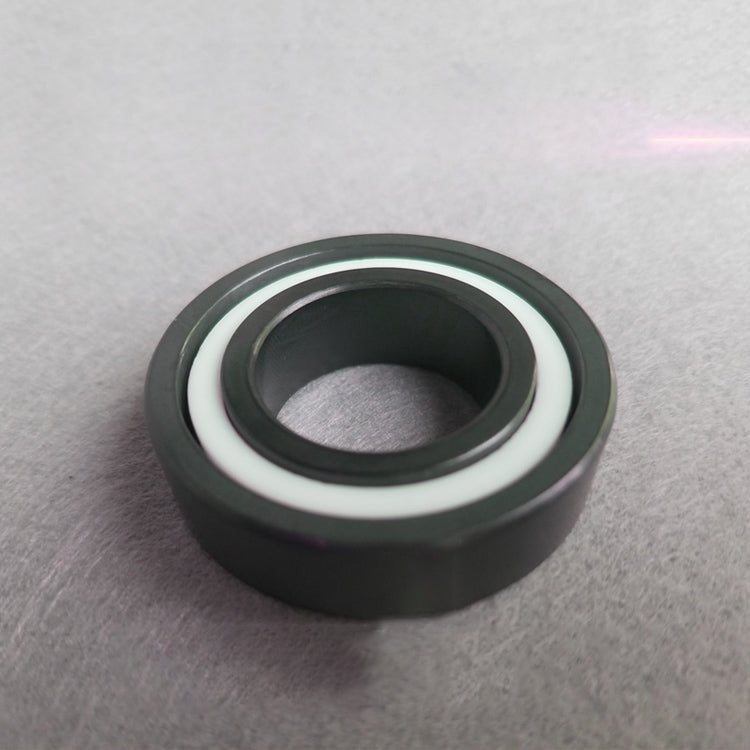

1. Product core introduction

Silicon Nitride Ceramic Bearings with High TEMP Resistance up to 1200℃ and Insulation, accompanied by a precision-engineered cage, are a revolutionary solution for industries operating in extreme thermal and electrical environments. These bearings are designed to meet the most challenging demands where conventional bearings would fail. By leveraging the unique properties of silicon nitride ceramic, we offer a product that not only provides reliable rotational support but also ensures safety and efficiency in high-temperature applications. Whether it's in the heart of a steel mill, the core of a power generation facility, or the crucible of advanced manufacturing processes, our bearings are the key to unlocking enhanced performance and durability, reducing downtime and maintenance costs while pushing the boundaries of what's possible in extreme conditions.

2. The main characteristics of the product

• Exceptional High-Temperature Resistance The silicon nitride ceramic material used in our bearings is specifically formulated to withstand temperatures as high as 1200℃. This remarkable property allows them to operate reliably in environments where other bearings would simply melt or degrade. The ceramic's inherent stability at extreme temperatures ensures that the bearing's structural integrity and performance are maintained, even under prolonged exposure to intense heat. This makes our bearings ideal for applications such as industrial furnaces, kilns, and high-temperature turbines.

• Outstanding Insulation Properties These bearings offer excellent electrical insulation capabilities, thanks to the non-conductive nature of silicon nitride ceramic. This insulation is crucial in applications where electrical conductivity could pose a safety hazard or interfere with the operation of sensitive equipment. In power plants, for example, the bearings prevent electrical current from passing through the rotating components, reducing the risk of short circuits and ensuring the smooth and safe operation of generators and motors. The insulation also helps to protect against electromagnetic interference, enhancing the performance of electronic components in proximity to the bearings.

• Precision-Machined Cage Design The accompanying cage is meticulously designed and precision-machined to enhance the overall performance and durability of the bearing. The cage not only provides proper spacing and guidance for the rolling elements but also contributes to the bearing's load-carrying capacity. It is engineered to withstand the high temperatures and mechanical stresses associated with the application, ensuring that the balls or rollers move smoothly and evenly within the raceways. The cage's design also aids in reducing friction and wear, further extending the life of the bearing.

• Low Friction and Wear Resistance Silicon nitride ceramic has a naturally low coefficient of friction, which means that our bearings operate with minimal resistance. This not only reduces energy consumption but also results in less wear and tear on the bearing components. The smooth operation of the bearings also contributes to a quieter and more efficient performance, making them suitable for applications where noise reduction and precision are important, such as in high-speed machinery and precision instruments.

• Chemical Resistance and Corrosion Protection In addition to their high-temperature and insulation properties, our bearings exhibit excellent resistance to a wide range of chemicals and corrosive substances. This makes them suitable for use in harsh industrial environments where exposure to acids, alkalis, and other corrosive agents is common. The chemical resistance of the silicon nitride ceramic helps to prevent the degradation of the bearing surfaces, ensuring long-term reliability and performance.

3. Product use scene

• Steel and Metal Processing Industry In steel mills, the bearings are used in various high-temperature equipment such as continuous casting machines, hot rolling mills, and annealing furnaces. The ability to withstand extreme heat and provide reliable rotation is essential for the smooth operation of these processes. The insulation properties also prevent electrical issues in the electrically charged environment of the mill, ensuring the safety of workers and the integrity of the production line.

• Power Generation Plants For coal-fired, gas-fired, and nuclear power plants, our bearings are used in turbines, generators, and other critical rotating equipment. The high-temperature resistance allows them to operate efficiently in the harsh conditions of the power generation process, while the insulation protects against electrical faults. The durability and reliability of the bearings contribute to the overall stability and productivity of the power plant, reducing maintenance downtime and increasing energy output.

• Aerospace and Aviation In aircraft engines and space exploration vehicles, the bearings are used in components that are exposed to high temperatures during operation. The lightweight and high-strength properties of silicon nitride ceramic, combined with its temperature resistance and insulation capabilities, make it an ideal choice for aerospace applications. The bearings help to reduce the overall weight of the vehicle while ensuring reliable performance in the extreme conditions of flight and space travel.

• Advanced Manufacturing and Research Facilities In industries such as semiconductor manufacturing, where precise control of temperature and electrical conditions is crucial, our bearings are used in vacuum chambers and high-temperature processing equipment. The insulation and high-temperature resistance ensure the integrity of the manufacturing process, while the low friction and wear characteristics contribute to the precision and repeatability of the operations. In research facilities, the bearings are used in experimental setups that involve extreme temperatures and electrical measurements, providing reliable data collection and analysis.

4. Product use instructions

1、Installation Before installation, ensure that the work area is clean and free from any debris or contaminants. Use clean, lint-free gloves to handle the bearing to prevent fingerprints and other residues from affecting its performance. Inspect the bearing for any signs of damage or defects, such as scratches, dents, or irregularities on the raceways or balls. If any issues are detected, do not install the bearing and contact the supplier for a replacement. When installing the bearing onto the shaft, use a gentle and even pressure to ensure proper seating. Avoid using excessive force, as this could cause damage to the bearing or the shaft. If necessary, use a suitable installation tool, such as a press fit sleeve or a bearing installer, to ensure accurate and damage-free installation. Ensure that the bearing is properly aligned with the shaft and the housing. Any misalignment can lead to increased wear and reduced bearing life. Use alignment tools or precision jigs to achieve the correct alignment, especially in applications where precision is critical.

2、Operation Start the equipment gradually and allow the bearing to warm up to its operating temperature. Avoid sudden starts and stops, as this can cause excessive stress on the bearing and lead to premature failure. Monitor the operating temperature, vibration, and noise levels of the bearing during operation. Any significant changes in these parameters could indicate a problem, such as insufficient lubrication, misalignment, or overloading. If detected, take immediate action to address the issue and prevent further damage. Ensure that the equipment is operating within the specified load and speed limits of the bearing. Exceeding these limits can significantly reduce the bearing's lifespan and may result in catastrophic failure. Refer to the product documentation or consult the supplier for the recommended operating parameters.

3、Maintenance Regularly clean the bearing and its surrounding area to remove any dirt, dust, or other contaminants that could accumulate during operation. Use a suitable cleaning solvent and a soft brush or cloth to gently wipe the bearing surfaces. Avoid using harsh chemicals or abrasive materials that could damage the bearing. Check the lubrication level and quality of the bearing regularly. The frequency of lubrication depends on the operating conditions and the type of lubricant used. Use a high-quality lubricant that is suitable for the application and the operating environment. Follow the manufacturer's recommendations for lubricant application methods and quantities. Periodically inspect the bearing for signs of wear, such as pitting, spalling, or increased clearance. If the bearing shows signs of significant wear, it should be replaced promptly to prevent further damage to the equipment. Use a micrometer or other precision measurement tools to accurately assess the bearing's condition.

• By following these guidelines, you can ensure the optimal performance and longevity of our Silicon Nitride Ceramic Bearings High TEMP Resistance 1200℃ Insulation With Cage in your applications. If you have any questions or need further technical assistance, please do not hesitate to contact our customer support team.