1. Product core introduction

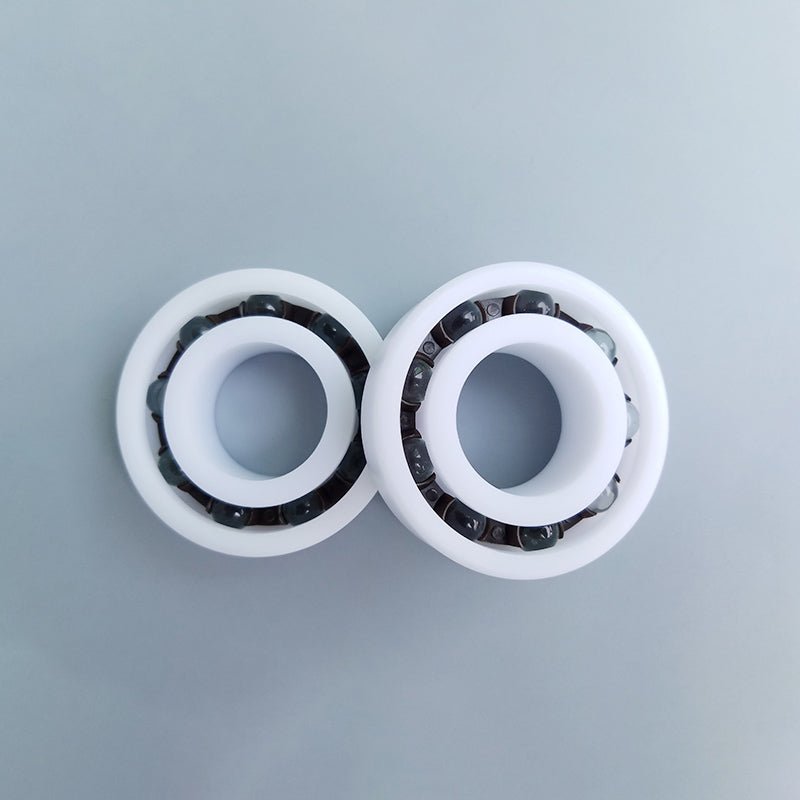

POM Plastic Bearing Glass Ball Miniature Deep Groove Ball Bearings are a revolutionary solution designed to meet the unique demands of modern, compact, and precision-driven applications. These bearings combine the best of advanced materials and engineering design to offer reliable and efficient rotational support in a miniature form factor. The use of POM plastic provides excellent chemical resistance and lightweight properties, while the glass balls ensure smooth and precise movement. Whether it's in the intricate mechanisms of electronics, the delicate instruments of the medical field, or the innovative designs of consumer products, our bearings are engineered to deliver outstanding performance, reducing friction, enhancing durability, and enabling the seamless operation of your equipment.

2. The main characteristics of the product

• POM Plastic Housing

The bearing's outer housing is crafted from POM (Polyoxymethylene) plastic, which offers remarkable chemical resistance. This makes the bearings suitable for use in environments where exposure to corrosive substances is a concern, such as in chemical laboratories, medical equipment, and certain industrial processes. The POM material also provides excellent dimensional stability, ensuring that the bearing maintains its shape and performance over time. Additionally, its lightweight nature is advantageous in applications where weight reduction is crucial, like in portable electronics and aerospace components.

• Glass Balls for Precision

The use of glass balls as the rolling elements brings several benefits. Glass balls are extremely smooth and hard, resulting in low friction and wear during operation. This enables the bearings to offer precise and smooth rotation, which is essential for applications that require high accuracy, such as in precision measuring instruments and optical equipment. The hardness of the glass balls also contributes to the overall durability of the bearing, allowing it to withstand repeated use without significant degradation.

• Miniature Deep Groove Design

The miniature deep groove ball bearing design allows for efficient load distribution and the ability to handle both radial and axial loads. The deep grooves provide a stable path for the glass balls to roll, minimizing the risk of ball skidding and ensuring reliable operation. The compact size of the bearing makes it ideal for use in tight spaces, where traditional bearings may not fit. This design feature is especially valuable in the development of miniaturized devices, such as wearable technology, micro-robots, and handheld medical devices.

• Low Friction and Quiet Operation

Thanks to the combination of the smooth glass balls and the precisely machined POM housing, our bearings operate with minimal friction. This not only reduces power consumption but also results in quiet operation, making them suitable for applications where noise reduction is important, such as in audio equipment and office machinery. The low friction characteristics also contribute to a longer service life by minimizing wear on the bearing components.

• Cost-Effective Solution

The use of POM plastic and glass balls offers a cost-effective alternative to traditional metal bearings, especially in applications where high-performance is required but budget constraints are a factor. The relatively low cost of materials and manufacturing processes makes these bearings an attractive option for mass-produced consumer products and small-scale industrial applications.

3. Product use scene

• Electronics Industry

In smartphones, tablets, and other handheld electronic devices, these bearings are used to support the rotation of components such as the camera module, vibration motor, and cooling fan. The miniature size and low friction characteristics are perfect for the compact and sensitive nature of these electronics, ensuring smooth operation and reducing power consumption. In hard disk drives, the bearings help to ensure the precise rotation of the spindle, allowing for rapid and accurate data access.

• Medical Devices

For insulin pumps, dialysis machines, and other implantable or handheld medical devices, the chemical resistance and biocompatibility of the POM plastic are essential. The precision and quiet operation of the bearings are also crucial in these applications, where accurate dosing and minimal patient discomfort are required. Surgical instruments that require smooth rotation, such as biopsy needles and arthroscopic tools, can also benefit from these high-quality bearings.

• Consumer Goods

In toys, small household appliances, and personal care products, the lightweight and cost-effective nature of the bearings make them a popular choice. For example, in electric toothbrushes, the bearings enable the smooth rotation of the brush head, enhancing the user experience. In toys with moving parts, such as remote-controlled cars and action figures, the bearings provide reliable and durable movement.

• Automotive Electronics

In automotive sensors, such as wheel speed sensors and throttle position sensors, the miniature bearings ensure accurate and reliable operation. The ability to withstand vibrations and temperature fluctuations in the automotive environment is also important. In electric vehicle motors and power electronics, the low friction and high precision of the bearings contribute to the efficient and reliable operation of these systems.

4. Product use instructions

1、Installation

Before installation, ensure that the work area is clean and free from any debris or contaminants. Use clean, lint-free gloves to handle the bearing to prevent fingerprints and other residues from affecting its performance.

Inspect the bearing for any signs of damage or defects, such as scratches, dents, or irregularities on the raceways or balls. If any issues are detected, do not install the bearing and contact the supplier for a replacement.

When installing the bearing onto the shaft, use a gentle and even pressure to ensure proper seating. Avoid using excessive force, as this could cause damage to the bearing or the shaft. If necessary, use a suitable installation tool, such as a press fit sleeve or a bearing installer, to ensure accurate and damage-free installation.

Ensure that the bearing is properly aligned with the shaft and the housing. Any misalignment can lead to increased wear and reduced bearing life. Use alignment tools or precision jigs to achieve the correct alignment, especially in applications where precision is critical.

2、Operation

Start the equipment gradually and allow the bearing to warm up to its operating temperature. Avoid sudden starts and stops, as this can cause excessive stress on the bearing and lead to premature failure.

Monitor the operating temperature, vibration, and noise levels of the bearing during operation. Any significant changes in these parameters could indicate a problem, such as insufficient lubrication, misalignment, or overloading. If detected, take immediate action to address the issue and prevent further damage.

Ensure that the equipment is operating within the specified load and speed limits of the bearing. Exceeding these limits can significantly reduce the bearing's lifespan and may result in catastrophic failure. Refer to the product documentation or consult the supplier for the recommended operating parameters.

3、Maintenance

Regularly clean the bearing and its surrounding area to remove any dirt, dust, or other contaminants that could accumulate during operation. Use a suitable cleaning solvent and a soft brush or cloth to gently wipe the bearing surfaces. Avoid using harsh chemicals or abrasive materials that could damage the bearing.

Check the lubrication level and quality of the bearing regularly. The frequency of lubrication depends on the operating conditions and the type of lubricant used. Use a high-quality lubricant that is suitable for the application and the operating environment. Follow the manufacturer's recommendations for lubricant application methods and quantities.

Periodically inspect the bearing for signs of wear, such as pitting, spalling, or increased clearance. If the bearing shows signs of significant wear, it should be replaced promptly to prevent further damage to the equipment. Use a micrometer or other precision measurement tools to accurately assess the bearing's condition.

• By following these guidelines, you can ensure the optimal performance and longevity of our POM Plastic Bearing Glass Ball Miniature Deep Groove Ball Bearings in your applications. If you have any questions or need further technical assistance, please do not hesitate to contact our customer support team.