1. Product core introduction

1.Choosing high-quality hardware is critical in home DIY projects, and HomeDIYer's 304 Stainless Steel Square Nut is the ideal choice. Designed to meet the needs of home DIY enthusiasts, these nuts provide a reliable connection solution for both small crafts and large home repairs.

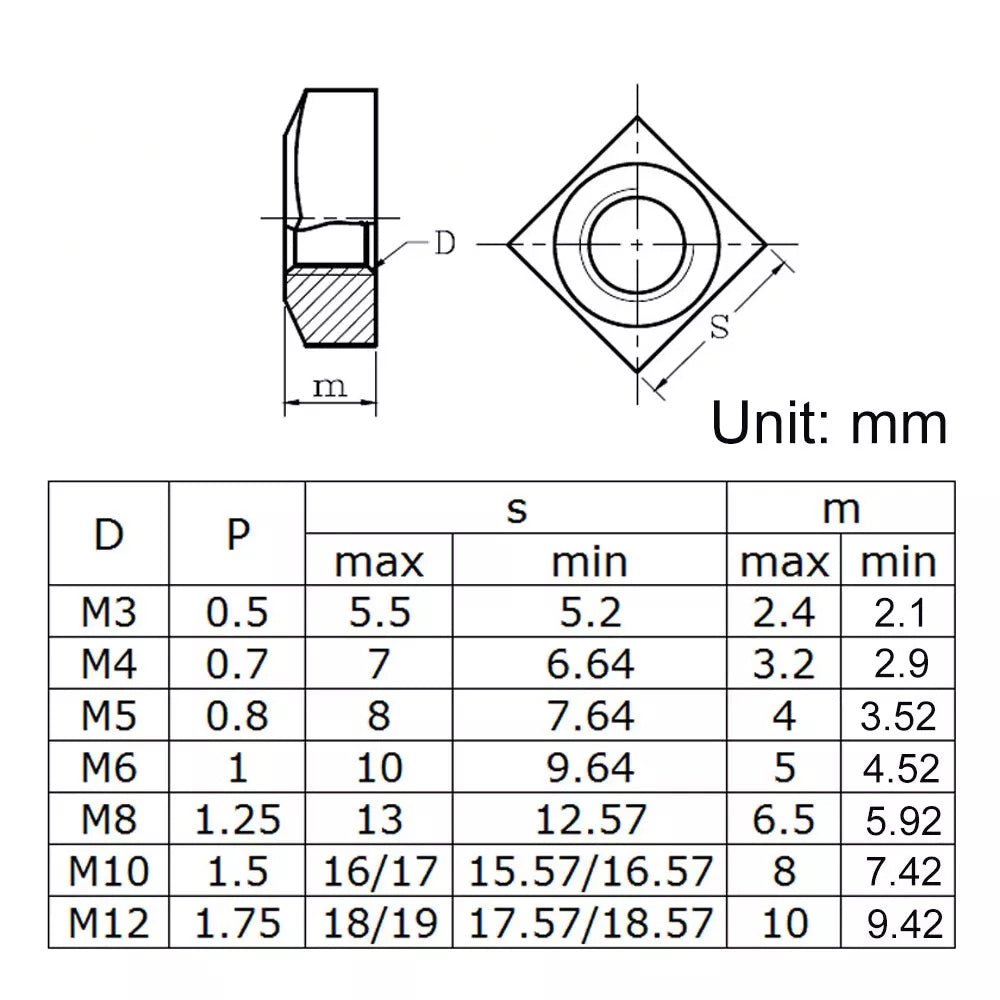

2.Our 304 Stainless Steel Square Nuts are made of high quality 304 Stainless Steel with excellent corrosion resistance and strength to maintain stable performance in a variety of environments. Available in sizes ranging from M3 to M12, it's easy to find the right size for your specific project, ensuring a perfect fit with other hardware components to create a sturdy and durable structure for your DIY projects.

2. The main characteristics of the product

HIGH QUALITY 304 STAINLESS STEEL MATERIAL: Made of high quality 304 stainless steel, this material contains 18% chromium and 8% nickel, which gives it excellent rust and corrosion resistance, able to withstand the common corrosive elements of daily life such as humidity, acid and alkali, ensuring that the nut remains bright and new after long-term use, will not rust or be damaged, and provides a long-lasting and reliable connection for your DIY projects.

Advantage of square design: The unique square structure design is one of the highlights of this product. Compared with traditional round nuts, the four corners of the square nut can provide a larger contact area, which can better distribute the pressure when tightening, effectively preventing the surface of the connected parts from indentation or deformation, and also increase the friction between the nut and the parts, making the connection more stable and reliable, and not easy to loosen even when subjected to large external forces.

Precise size specification: Each size of the nuts, from M3 to M12, is controlled by strict production process to ensure precise size. The threaded part is processed with high precision, fits tightly with the corresponding bolts and installs smoothly, avoiding the problem of difficult installation or poor connection due to the size deviation, making your DIY operation more convenient.

GOOD MECHANICAL PROPERTIES: 304 stainless steel material gives the nut good mechanical properties, including high hardness and toughness. This makes the nuts perform well when subjected to tensile, pressure and shear forces, and can meet the requirements of different types of DIY projects on the strength of the connection, whether it is used for fixing the frame of furniture, connecting the parts of mechanical equipment, or building small metal structures, it can provide reliable support.

3. Product use scene

1.Furniture assembly and maintenance: When assembling wooden furniture, such as tables, chairs, bookshelves, closets, etc., the 304 stainless steel square nuts can be used with bolts to connect the various parts and ensure the structure of the furniture is stable. Its square design can better fit the surface of wood, prevent the nut from rotating or loosening during use, and improve the stability and safety of furniture. In terms of furniture maintenance, if the original nut is rusted or damaged, use this product to replace it, not only to restore the normal use of furniture, but also to enhance its durability and aesthetics, so that your furniture a new look.

2. Home decoration installation: For the installation of home decorations, such as picture frames, mirrors, chandeliers, etc., this nut can also play an important role. When fixing picture frames or mirrors, its precise size and good anti-rust performance can ensure that the decorations hang smoothly and remain beautiful for a long time. When installing chandeliers, the square nut can provide a reliable connection to ensure that the chandelier hangs safely, adding a warm and cozy atmosphere to the home environment.

3. Small equipment construction and repair: when you build or repair some small equipment, such as homemade small electrical appliances, mechanical models, bicycle repair, etc., these nuts are indispensable connectors. Their high strength and corrosion resistance can meet the requirements of the connecting parts of the equipment in the process of operation and ensure the normal operation and stability of the equipment. For example, in homemade small robots, the use of 304 stainless steel square nuts to connect metal frames and motors and other components can ensure that the robot in the process of movement of the structure is solid, not easy to loosen or damage the situation.

4. Product use instructions

Choose the right specification: According to the requirements of your DIY project and the size of the matching bolt, carefully choose the corresponding specification of 304 stainless steel square nuts. Make sure the thread size of the nut matches the bolt exactly to ensure a tight and stable connection. You can refer to the design drawings of the project or actually measure the hole diameter and thread size of the required connecting parts to select the most suitable nut specification.

Preparation for installation: Before installing the nut, clean the surface of the connected parts to remove impurities such as oil, dust, rust, etc., and make sure the surface is flat and clean. This will improve the friction and fit between the nut and the component, making the connection more solid and reliable. For some connection parts that require precise alignment, appropriate tools can be used to locate and assist installation, such as clamps or locating pins.

Installation method: Align the nut with the threaded end of the bolt and gently screw it in by hand for a few turns to ensure that the threads are initially aligned. Then, using a suitable wrench or screwdriver (selected according to the size of the nut and tightening requirements), gradually tighten the nut in a clockwise direction. During the tightening process, pay attention to the even application of force to avoid over-tightening resulting in thread damage or deformation of the connected parts. For some projects that require tightening torque, a torque wrench can be used to tighten according to the specified torque value to ensure the safety and reliability of the connection. Generally speaking, the tightening torque for nuts of smaller sizes (e.g. M3 - M6) is relatively small, while nuts of larger sizes (e.g. M8 - M12) require a larger tightening torque, but the specific value should be adjusted according to the actual use and the material and structure of the components.

Inspection and maintenance: After completing the installation of the nut, carefully check whether the connection part is firm and whether the nut is tightened in place. The stability of the connection can be tested by gently shaking or applying certain external force. Regularly check the use of the nuts, especially in projects that have been used for a long time or exposed to harsh environments. If the nuts are loose or show signs of rust, they should be tightened or replaced in a timely manner. If there is dirt or dust on the surface of the nut, it can be wiped clean with a clean cloth to avoid dirt buildup affecting the performance and appearance of the nut.