1. Product core introduction

HomeDIYer has always been focusing on providing high quality, high performance hardware for home DIY enthusiasts, and this 316 stainless steel pan head machine screw is one of the fine products we have crafted.

Our M3, M4, M5 and M6 sizes have been carefully selected to meet the common needs of most home DIY projects, whether it's for small electronics assemblies, medium-sized furniture making, or equipment repairs and modifications that require strength and stability.

Using 316 stainless steel as the raw material, which is a material with excellent performance in corrosion resistance, compared with ordinary stainless steel, it can maintain stable performance in more harsh environments, whether it is long-term exposure to wet outdoor environments, or indoor environments with certain chemical substances (such as kitchens, bathrooms, etc.), will ensure the structural integrity and reliability of the screws, to provide you with DIY works of Long-term support and protection for your DIY works.

2. The main characteristics of the product

Top quality 316 stainless steel material: 316 stainless steel is known for its excellent corrosion resistance. It contains the element molybdenum, which makes it excellent in terms of resistance to corrosion by seawater and chemical media, and enables it to easily cope with the various corrosive factors that may be encountered in the domestic environment, such as humid air, salt, cleaning agent residues, and so on. This not only ensures that the screws will not rust and corrode during long-term use, thus maintaining good appearance and mechanical properties, but also greatly extends their service life and reduces the frequency of replacement due to screw damage, providing a reliable and long-lasting fastening solution for your DIY projects.

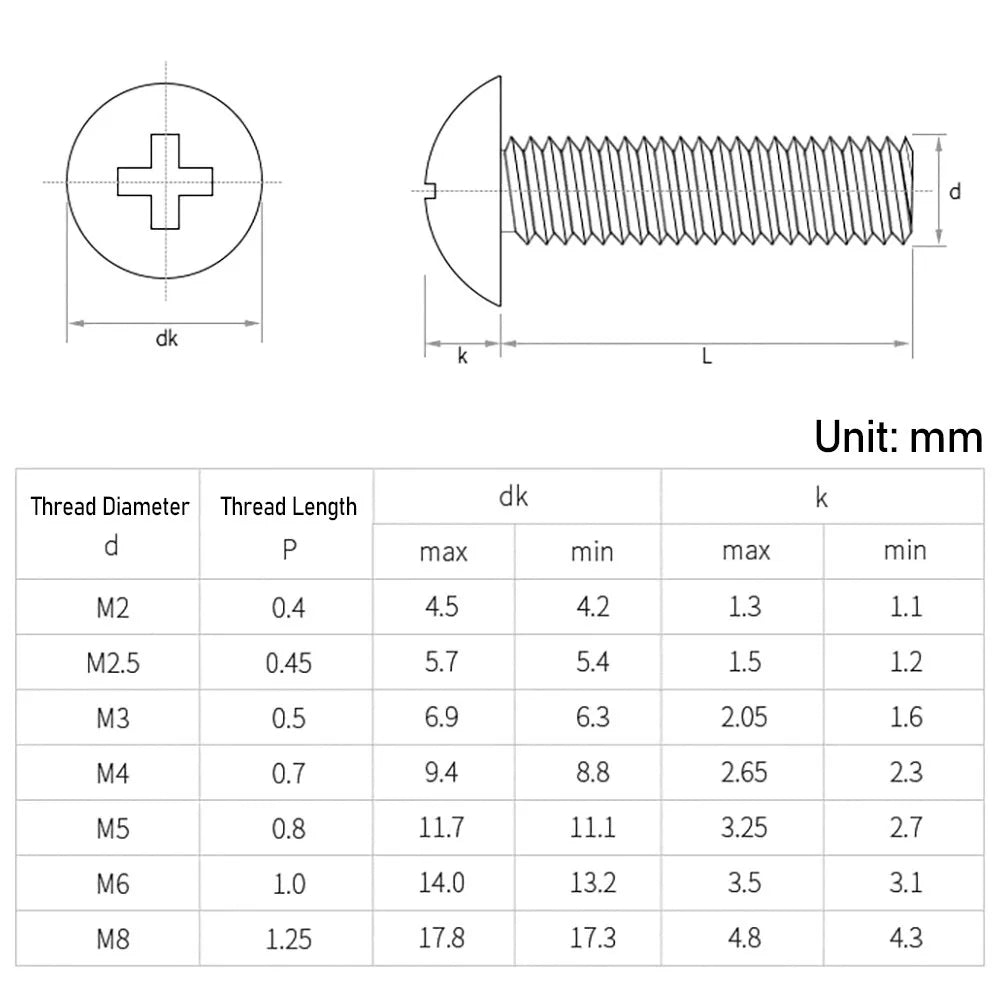

Precise dimensional tolerances: Through advanced production processes and strict quality control systems, we ensure that each screw has a very small tolerance range in terms of diameter (M3 - M6) and other dimensions. This means that screws and nuts, screw holes and other supporting components can achieve a high-precision close fit, more stable after installation, effectively preventing the occurrence of loosening and displacement phenomenon. In some DIY projects that require high precision, such as the assembly of precision instruments or the repair of small electronic products, such precise dimensional tolerances can ensure that the connection between the various components is accurate, thus guaranteeing the normal operation and stability of the entire equipment or structure.

Advantage of plum groove design: The unique design of plum groove is a major highlight of this product. Compared with the traditional cross slot or one-slot, the contact area between the plum groove and the screwdriver is larger, which can provide a more stable torque transmission and effectively reduce the possibility of slipping of the screwdriver in the process of screwing screws. This makes the installation and removal of screws easier and faster, especially in the case of multiple tightening or loosening of screws, which can greatly improve work efficiency, and also reduces the risk of damage to the screw slot or screwdriver bit due to improper operation, which brings a smoother and more convenient experience for your DIY operation.

Plate head shape is both beautiful and practical: the design of the plum blossom plate head not only looks beautiful and generous in appearance, in line with modern aesthetic trends, but also has important functional value in practical use. Plate head and the contact area of the fixed parts is large, can evenly disperse the pressure, to avoid damage to the surface of the material due to pressure concentration, especially in the fixing of some softer or thinner materials, this advantage is more obvious. At the same time, in application scenarios that require greater tensile force or pressure, the disk head can provide better support and stability to ensure more reliable fastening effect, so that your DIY project will always remain strong and durable in the long-term use of the process, adding a sense of professionalism to your creative work.

3. Product use scene

High-end Furniture Making and Repairing: When making high-end wooden furniture (such as solid wood cabinets, carved closets, exquisite desks, etc.), 316 stainless steel screws from M3 - M6 provide excellent tightening effect and aesthetics. Their stainless steel luster complements the wood material and the plum disc head design can be hidden under the wood surface, which does not affect the overall aesthetics of the furniture and ensures a strong connection between the various components. In furniture maintenance, such as replacing damaged hinges, drawer guides or repairing loose table and chair legs, the corrosion resistance and high strength of these screws can ensure that the repaired furniture can continue to be used stably for a long time, prolonging the service life of the furniture and adding a quality and style to your home environment.

Precision equipment assembly and maintenance: For some precision equipment in the home, such as small 3D printers, homemade electronic equipment, high-end audio systems, etc., 316 stainless steel screws of M3 - M4 are the ideal choice. Their precise dimensional tolerances and stable mechanical properties ensure that the precise connections between the various precision components within the equipment are accurate and that the normal operation of the equipment is not compromised by loose or corroded screws. In the process of equipment maintenance, the easy removal and installation of these screws can also save you time and energy, so that you can more conveniently carry out equipment maintenance and upgrading, to ensure that your precision equipment is always in the best condition, to meet your pursuit of high-tech DIY projects.

Outdoor facilities construction and reinforcement: If you build outdoor facilities in your home garden or balcony, such as metal flower racks, awnings, small barbecue grills, etc., 316 stainless steel screws from M4 - M6 will be your right-hand man. Outdoor environments are often harsh, with rain, sun, sand and other corrosive elements, and the superior corrosion resistance of 316 stainless steel screws ensures that these installations remain sturdy even after prolonged exposure to the outdoors. Its high-strength characteristics can also withstand various external impacts that may be encountered during the use of outdoor facilities, such as wind, sun, rain, etc., to provide safe and reliable protection for your outdoor life, so that you can enjoy your outdoor leisure time.

4. Product use instructions

Tool Preparation: According to the size of the screws you are using (M3 - M6), select the appropriate size matching screwdriver, make sure that the size and shape of the screwdriver bit and the screw's socket can be closely and accurately fit. Using an unsuitable screwdriver may cause damage to the screw slot, affecting the normal use and removal of the screw, and may also damage the screwdriver bit, reducing the service life of the tool. Therefore, choosing the right tool is the first step to a smooth DIY operation.

Preparation before installation: Before installing the screws, be sure to clean and pre-treat the surface of the parts to be fixed. Remove dust, oil, rust and other impurities on the surface, which may affect the friction and tightening effect between the screws and components, resulting in loose screws or poor installation. For harder metal materials or in some parts that need to withstand greater pressure, it is recommended to pre-drill pilot holes slightly smaller than the diameter of the screws using a suitable drill bit according to the diameter of the screws. This will reduce the resistance when screwing in the screws, prevent the material from cracking or deforming during installation, and also help to ensure that the screws can be installed vertically and accurately in place, improving the precision and stability of the installation.

Installation process: Align the screws with the pre-drilled holes (if any) or directly to the position where they need to be fixed, then use a plum screwdriver to slowly screw in the screws perpendicular to the mounting surface. At the beginning, gently rotate the screwdriver so that the screws initially enter the holes. At this time, special attention should be paid to confirm that the screws are correctly positioned and perpendicular to avoid tilting or skewing. As the screws gradually into the hole, gradually increase the rotating force, but in the whole process should always maintain an even application of force, to prevent the screw threads due to over-exertion of force caused by damage or cracking of the fixed parts. If you feel greater resistance during the screwing process, you can pause to check whether the screw is vertical and whether there is any foreign object blocking the hole. If necessary, a small amount of lubricant (e.g. lubricant or graphite powder) can be used to coat the screw threads, but care should be taken to avoid the lubricant contaminating other parts or affecting the tightening effect. Through correct and standardized operation, ensure that the screws can be firmly installed in place and achieve the desired tightening effect, providing a reliable connection guarantee for your DIY projects.

Removal Steps: If you need to remove the installed screws later, first choose a suitable screwdriver and insert its bit accurately into the screw's socket, making sure that the bit fits tightly into the slot. Then, slowly rotate the screwdriver in the counterclockwise direction to gradually loosen the screw. During the loosening process, the screwdriver should also be kept vertical to prevent slippage. If the screws become tighter because they have not been disassembled for a long time, rust or other reasons, you can first drop the appropriate amount of rust remover or lubricant around the screws, and wait for a period of time (generally a few minutes to ten minutes, depending on the actual situation), so that the lubricant fully penetrates into the threaded gap, and then try to unscrew the screws. This can greatly reduce the difficulty of disassembly, and at the same time protect the screws and the threads of the fixed parts from damage, making it easier for you to carry out subsequent adjustments, repairs or replacements, and ensuring that your DIY project has good maintainability.