1. Product core introduction

The KSD301 temperature switch and controller from HomeDIYer has both normally open and normally closed modes of operation, with a rated voltage of 250V and a rated current of 10A. It ensures that your equipment operates stably at the right temperature by precisely adjusting the temperature, which is a key component in guaranteeing the safe and stable operation of equipment, whether it is a DIY project, a household appliance, or an industrial device, and it can effectively satisfy your needs for temperature control. It is the key component to ensure the safe and stable operation of the equipment.

2. The main characteristics of the product

Stable temperature control performance: Using advanced temperature sensing technology, it can accurately sense the ambient temperature and act quickly and accurately at the set temperature point to effectively control the heating or cooling system of the equipment to ensure that the temperature is maintained within the required range. Whether in the low-temperature environment of the heating start, or high-temperature environment of the cooling adjustment, can be stable and reliable operation, to provide continuous and stable temperature protection for the equipment, to reduce the damage caused by temperature fluctuations on the equipment, to extend the service life of the equipment.

Flexible switching of normally open/normally closed mode: Users can freely choose normally open or normally closed working mode according to the actual application scenario and the control logic of the equipment. Normally open mode, when the temperature is lower than the set value, the switch remains disconnected, once the temperature rises to the set threshold, the switch closes and connects the circuit, suitable for automatic start-up control of heating equipment; Normally closed mode, on the contrary, the switch closes when the temperature is normal, and automatically disconnects when the temperature is out of the set range, cutting off the power supply, preventing the equipment from being damaged due to overheating, this flexible mode switching greatly enhances the versatility and adaptability of the product. This flexible mode switching function greatly enhances the versatility and adaptability of the product and meets the diversified control needs of different equipment.

High voltage and high current carrying capacity: the rated voltage of 250V and rated current of 10A parameter design, so that it can meet the power requirements of most common electrical equipment, can be directly applied to various types of medium and high power heating, cooling or temperature control equipment, without additional configuration of complex voltage and current conversion or amplification circuits, to simplify the design of the electrical system of the equipment, and at the same time ensure that in the high-load operating conditions of stability and reliability, for the high efficiency of the equipment, and to ensure the stability and reliability of the equipment. At the same time, it ensures the stability and reliability under high load operation conditions, providing solid power support for the efficient operation of the equipment.

Reliable safety protection mechanism: Built-in multiple safety protection functions, the switch can quickly and automatically cut off the power supply when the equipment has an abnormal temperature rise or circuit failure resulting in excessive current, effectively preventing fire, equipment damage and other safety accidents caused by overheating, and providing a strong guarantee for the safety of users' lives and properties. Its shell is made of high-temperature-resistant, good insulating materials, which further enhances the safety and reliability of the product, and it can run stably even under the harsh working environment, so that users can use it with more peace of mind.

3. Product use scene

Temperature control in DIY projects: The KSD301 temperature switch can be used as the core temperature control component in DIY enthusiasts' homemade equipment, such as homemade small greenhouse control systems, aquarium water temperature regulators, electronic baking equipment, etc. The KSD301 temperature switch can be used as the core temperature control component in DIY projects. By accurately setting the temperature range, it can realise the automatic control of heating or cooling equipment, create a suitable temperature environment to meet the specific needs of plant growth, aquarium organisms survival or food baking, etc. It ensures that the DIY projects are carried out smoothly and the expected results are achieved, and provides a reliable temperature guarantee for the creative practice.

Temperature control of household appliances: Widely used in all kinds of household appliances, such as electric heaters, air conditioners, electric water heaters, refrigerators, ovens and so on. Take the electric heater as an example, when the indoor temperature reaches the comfortable temperature set by the user, KSD301 temperature switch will automatically cut off the power supply of the heating element, avoiding the waste of energy and safety hazards caused by overheating; in the refrigerator, through the precise control of the refrigeration system, it maintains a stable and low temperature in the refrigerator and freezer to ensure the freshness and quality of food; in the oven, it can be used according to the baking requirements of different ingredients to In the oven, according to the baking requirements of different ingredients, the heating temperature and time can be accurately controlled to realise the perfect preparation of delicious food and enhance the convenience, comfort and safety of household appliances.

Temperature management of industrial equipments: In the field of industrial production, many equipments need strict temperature control, such as industrial furnaces and kilns, injection moulding machines, chemical reactors, motor cooling systems, etc. KSD301 temperature switch can monitor the operating temperature of the equipments in real time according to the requirements of the process and adjust the working status of the heating or cooling devices in time to ensure that the industrial equipments are operated in the optimal temperature conditions and improve the productivity and stability of the product quality. Stability of product quality. For example, in injection moulding machines, precise control of the heating and cooling temperatures of moulds helps to ensure the moulding quality and dimensional accuracy of plastic products; in motor cooling systems, by automatically adjusting the speed of the cooling fan or the flow rate of the coolant, it prevents the motor from being damaged due to overheating, and safeguards the continuity and stability of industrial production.

4. Product use instructions

Preparation before installation:

Check the appearance of the product for defects such as damage, deformation, bent pins or oxidation, if there is any problem, contact the supplier for replacement in time to ensure that the quality of the KSD301 temperature switch used is intact and undamaged.

Determine the required switch operating mode (normally open or normally closed) according to the actual control requirements and electrical parameters of the equipment, and prepare suitable installation tools, such as screwdrivers, wrenches, wire strippers, soldering iron, etc., and make sure that the tools are clean and in good condition, so as not to damage the switch during the installation process.

Installation and Connection:

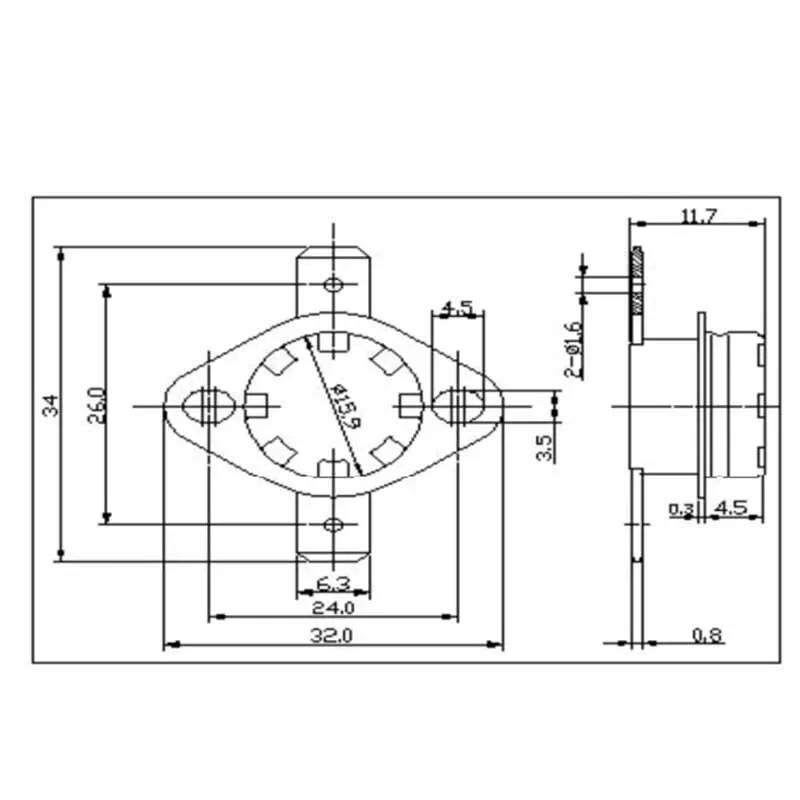

Install the KSD301 temperature switch in a location in the equipment where it can accurately sense temperature, ensuring that its temperature-sensing part is in close contact with the object being monitored to obtain an accurate temperature signal. For mounting that requires fixing, use the matching screws or clips to mount the switch securely in the specified location to avoid loosening or displacement during equipment operation.

According to the pin definition of the switch and the electrical connection requirements of the equipment, use wires of appropriate specifications to connect the switch to the circuit correctly. During the connection process, pay attention to the proper stripping length of the wires to ensure a firm and reliable connection to avoid problems such as false connections and short circuits. If the welding connection is used, the welding time and temperature should be controlled to ensure that the solder joints are full, smooth and free of false welding; for plug-in connection, make sure that the plug and socket are closely matched and inserted at the right depth to prevent circuit failure due to poor contact.

Temperature setting and debugging:

Before the equipment is used for the first time, set the temperature of KSD301 temperature switch according to the actual application scenario and the working temperature requirement of the equipment. The desired action temperature value can usually be set by rotating or adjusting the temperature adjustment knob on the switch to match the optimum operating temperature of the equipment. When setting the temperature, reference should be made to the equipment's technical manual and the actual operating environment to ensure the accuracy and reasonableness of the temperature setting.

After completing the temperature setting, carry out power-on test on the equipment and use professional thermometer or temperature measuring instrument to monitor and record the actual operating temperature of the equipment. Observe whether the temperature control switch acts accurately at the set temperature point. If the temperature control is found to be inaccurate or the switch acts abnormally, check whether there are any problems with the temperature setting, installation position, circuit connection and temperature sensing element in time, and make corresponding adjustments and repairs, so as to ensure that the temperature control switch can work normally and meet the temperature control requirements of the equipment.

Precautions for use:

During the operation of the equipment, avoid applying excessive external force, vibration or shock to the KSD301 temperature switch, so as not to affect its temperature sensing performance and the accuracy of the switch action. At the same time, be careful to prevent water, oil, dust, corrosive gases and other impurities into the switch, affecting its normal operation and service life. If the working environment of the equipment is relatively harsh, consider taking appropriate protective measures, such as the addition of shields, gaskets, filters, etc., to effectively protect the temperature control switch.

Regularly check and maintain the temperature control system of the equipment, including checking whether the appearance of the temperature control switch is damaged, whether the connection is loose, whether the temperature setting is shifted, whether the temperature sensing element is normal and so on. If problems are found, they should be repaired or replaced in time to ensure that the temperature control switch is always in a good working condition and to guarantee the safe and stable operation of the equipment.