1. Product core introduction

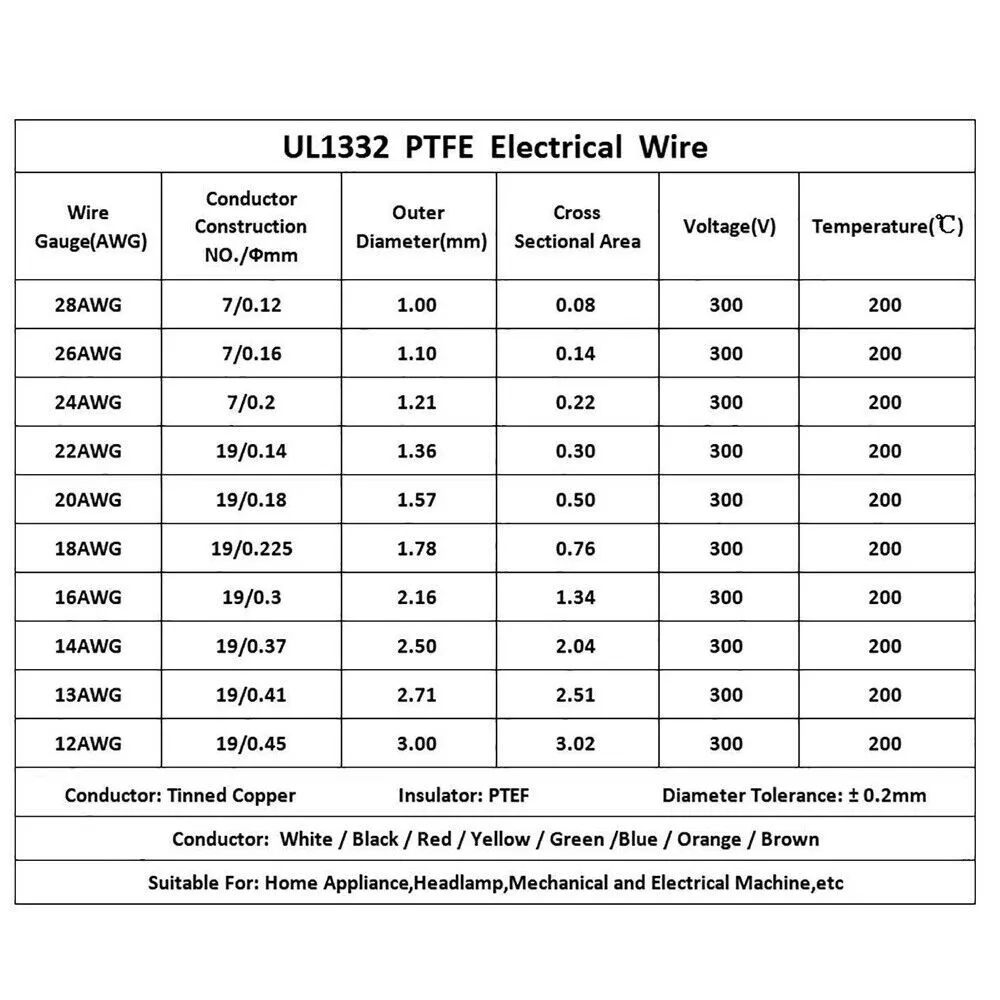

The UL1332 PTFE cable from HomeDIYer is a high-performance wire designed for high-temperature environments, using flexible tinned copper as the conductor. Available in sizes from 14 AWG to 28 AWG and in 6 colours to meet the diverse needs of different users. Manufactured in accordance with UL1332, the cable provides a stable and reliable power transmission solution for your projects in the fields of electronics manufacturing, automotive retrofitting, and industrial equipment maintenance, and ensures stable electrical performance even under high-temperature conditions.

2. The main characteristics of the product

Excellent high-temperature resistance: the use of polytetrafluoroethylene (PTFE) insulation material, with excellent high-temperature resistance, can work stably for a long time in high-temperature environments, and its temperature resistance is much higher than that of ordinary cable materials, suitable for electrical connections in high-temperature areas such as engine compartments, high-temperature industrial furnaces and other areas, to ensure that the line is still able to operate normally in extreme conditions, and will not be high-temperature caused by the aging of the insulation, short-circuiting and other problems. Problems.

Flexibility: Despite its high temperature resistance, the cable remains flexible, making it easy to route in a variety of complex installation environments. Whether it is a narrow space, or the need for frequent bending parts, can easily cope with, greatly reducing the difficulty of installation, improve the efficiency of work, but also reduces the risk of loosening or damage to the connection parts caused by the cable is too hard.

High-quality tinned copper conductor: The conductor is made of tinned copper, which not only has good electrical conductivity, can effectively reduce the resistance and reduce the energy loss in the power transmission process, but also has strong oxidation and corrosion resistance to ensure long-term stable electrical performance. Even in the humid, acid and alkali and other harsh environmental conditions, can maintain a good conductive state, extend the service life of the cable, for your electrical system to provide reliable power transmission security.

A wide range of sizes and colours: With a wide range of sizes from 14 AWG to 28 AWG, users can precisely choose the right wire diameter according to the actual current carrying requirements and equipment compatibility, thus achieving optimal allocation of resources. Meanwhile, the 6 colours are designed to facilitate users to differentiate and identify the wires in the complex wiring system, which is convenient for the management and maintenance of the wires, and improves the accuracy and convenience of the work.

Compliance with UL1332 standard: Strictly manufactured and tested according to UL1332 standard, which means that the cable has been rigorously verified by authoritative institutions in terms of electrical performance, safety and reliability, and complies with internationally recognised quality standards. Users can use it without worrying about the quality of the product, providing you with peace of mind whether for professional industrial applications or home DIY projects.

3. Product use scene

Automotive electronic system: in the engine compartment of the car, used to connect a variety of high temperature sensors, ignition system, electronic control unit (ECU) and other components, able to withstand the high temperature environment generated by the engine operation, to ensure the stable operation of the automotive electronic system, to enhance the performance and reliability of the car. At the same time, in the car audio system upgrades, lighting modification, etc., its flexibility and a variety of colour options also provide convenience for wiring, to meet the personalized needs of car modification enthusiasts.

Industrial Equipment Manufacturing and Maintenance: Widely used in various high-temperature equipment in the industrial field, such as industrial furnace, heat treatment equipment, injection moulding machines and other electrical connections and control systems. It can stably transmit power and signals under high temperature and high load working conditions to ensure the continuity and safety of industrial production. In the regular maintenance and repair of industrial equipment, its good flexibility and marking are also convenient for technicians to carry out line inspection and replacement, reducing maintenance costs and time.

Aerospace (non-critical flight systems): In the ground test equipment of some aerospace equipments, auxiliary electronic systems and the component connection of non-critical flight systems, its high temperature resistance and reliable performance can be utilised to ensure the stability of the electrical connection in the simulated flight environment and ground maintenance process. Although they cannot be used in critical flight systems, they provide a certain level of support and assurance for aerospace projects in related peripheral equipment and test scenarios.

R&D and production of electrical and electronic products: For electrical and electronic products that require performance testing or long-term stable operation in high-temperature environments, such as high-temperature ovens, industrial-grade power supplies, electronic test equipment, etc., this cable can be an ideal choice for internal electrical connections. Its precise specifications and reliable performance help R&D personnel to accurately assess the performance of products under high temperature conditions, ensure product quality and stability, and meet the market demand for high-quality electrical and electronic products.

4. Product use instructions

Pre-installation Preparation:

Carefully check the appearance of the cable for defects such as breakage, scratches, flaking insulation, etc. Especially when used in high temperature areas, any minor damage may affect the performance and life of the cable. If problems are found, stop using it immediately and contact the supplier for replacement.

Determine the required cable specifications (14 AWG - 28 AWG) and colours according to actual usage scenarios and equipment connection requirements, and prepare installation tools such as corresponding stripping tools, crimping pliers, soldering equipment (if required), etc., and make sure of the precision and applicability of the tools, so as to avoid damage to the cables in the installation process.

Wiring and connection:

In the wiring process, the cable should be reasonably planned according to the actual installation path and environmental conditions to avoid excessive bending, twisting or stretching the cable. At the same time, care should be taken to avoid direct contact between the cable and high-temperature parts, and if necessary, heat-insulating measures should be taken.

When connecting with equipment, first use wire stripping tools to carefully strip off the insulation at the end of the cable, exposing the appropriate length of tinned copper conductor, and then insert the conductor into the connection terminal and firmly press it with crimping pliers to ensure a reliable connection and good contact. If soldered connections are required, suitable solder and soldering techniques should be used to ensure that the solder joints are firm, smooth and free from false soldering. After the connection is completed, the connection is carefully insulated and can be wrapped with insulating tape or heat-shrinkable tubing to prevent leakage and short-circuit accidents.

Precautions for use:

The rated voltage and current of this cable should be used in strict accordance with the parameters on the product specification, and should not exceed the maximum value specified therein, so as not to cause electrical safety accidents, damage to equipment or personal injury. When connecting multiple devices, pay attention to calculating the total power and current to ensure that the cable can withstand the load.

Although the cable has high temperature resistance, it should still try to avoid prolonged exposure to environments exceeding its rated temperature, so as not to accelerate the aging of the insulating material and performance degradation. When used in high-temperature environments, regularly check the operating status of the cable, including the appearance, connection parts, etc., and if any abnormality is found, timely measures should be taken to repair or replace it.

Avoid the cable contact with humidity, corrosive chemicals and other harsh environmental conditions, if it can not be avoided, should take appropriate protective measures, such as the use of waterproof, corrosion-resistant trunking or casing to protect the cable, in order to prolong the service life of the cable and ensure the stability of its performance.

Regularly check the connection parts and overall appearance of the cable to see if there is any looseness, oxidation, breakage and so on. If problems are found, they should be repaired or replaced in time to ensure the normal operation and electrical safety of the cable. At the same time, when carrying out equipment maintenance or overhaul, attention should be paid to the protection of cables to avoid damage caused by human factors.