Discover the perfect fastener for your next project with HomeDIYer’s Machine Screws Collection. Whether you’re a professional contractor, a hobbyist, or a DIY enthusiast, our extensive selection of high-quality machine screws ensures you’ll find the right fit for any application—from assembling furniture to repairing machinery.

Recommended Product Category

Homediyer’s machine screws are engineered for secure fastening in pre-tapped holes or with matching nuts. Ideal for machinery, electronics, and appliances, these screws offer unmatched durability and precision. Available in stainless steel, brass, and zinc-plated finishes for corrosion resistance.

- Materials: Stainless steel (304/316), brass, zinc-plated steel

- Head Types: Flat head, pan head, round head, socket head

- Drive Types: Phillips, slotted, Torx, hex socket

- Sizes: #2 to #12, lengths ⅛” to 3”

- Features: Fully threaded, compatible with standard nuts, ANSI-compliant

The Ultimate Guide to Machine Screws: Sizes, Types, and Expert Tips

Machine screws are essential fasteners for DIY enthusiasts, engineers, and anyone tackling home improvement projects. Whether you’re building furniture, repairing appliances, or working on a custom metal fabrication, understanding the nuances of machine screws—from sizes and materials to head types and applications—is crucial. In this comprehensive guide, we’ll break down everything you need to know, including machine screw size charts, dimensions, and where to buy the best-quality screws for your needs.

1. What Are Machine Screws?

Machine screws are threaded fasteners designed to be used with pre-tapped holes or nuts. Unlike wood screws, they don’t taper at the tip and are typically smaller in diameter. They come in a variety of materials, including stainless steel, brass, and copper, each suited for different environments. For example:

- Stainless steel machine screws resist corrosion, making them ideal for outdoor projects.

- Brass machine screws offer a decorative finish and are often used in electronics.

- Slotted or flat head machine screws provide a flush finish for aesthetic applications.

Pro Tip: Always match the screw material to your project’s requirements. For instance, use self-tapping machine screws for metal-to-metal connections without pre-drilled holes.

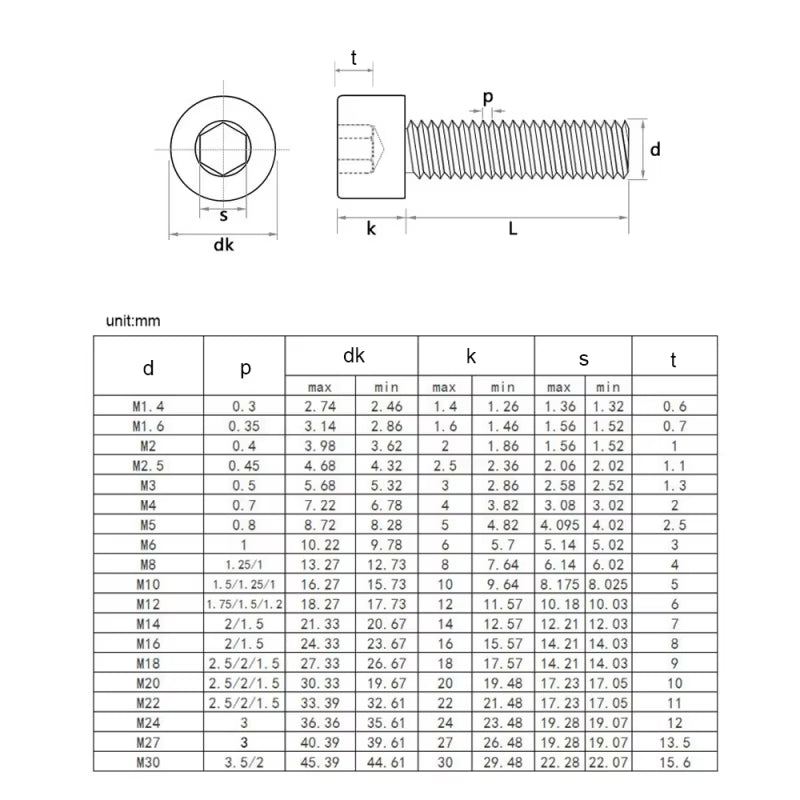

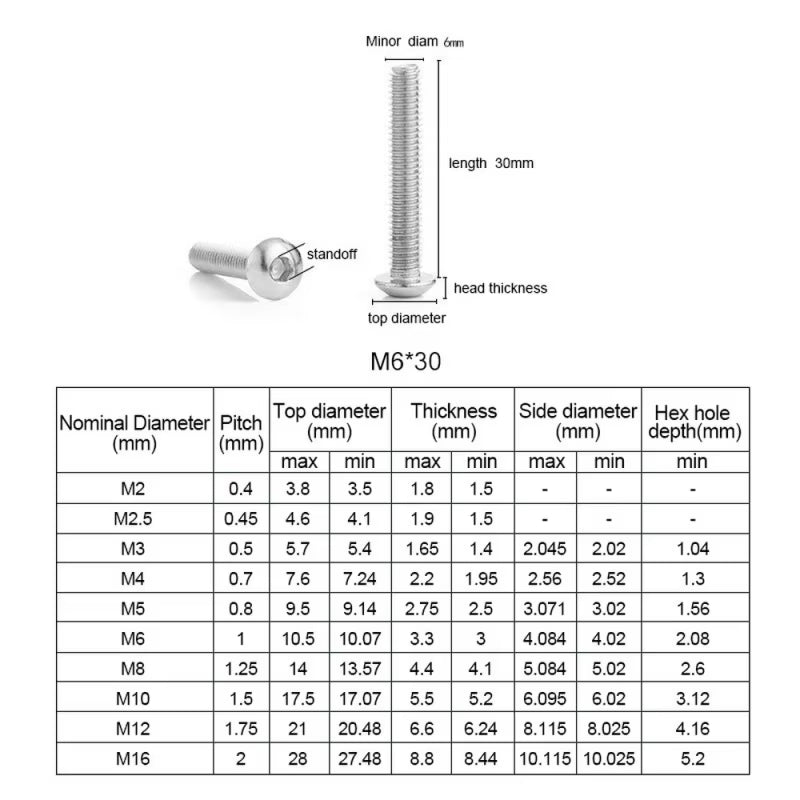

2. Machine Screw Sizes and Dimensions Explained

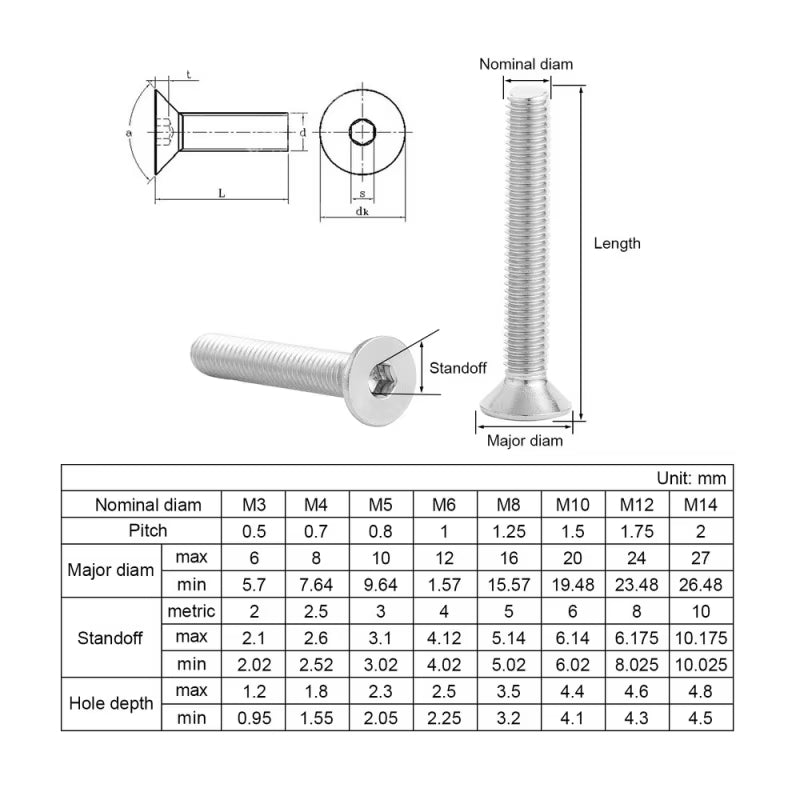

Choosing the right size is critical. Machine screws are measured by diameter, length, and threads per inch (TPI). Here’s how to decode common labels:

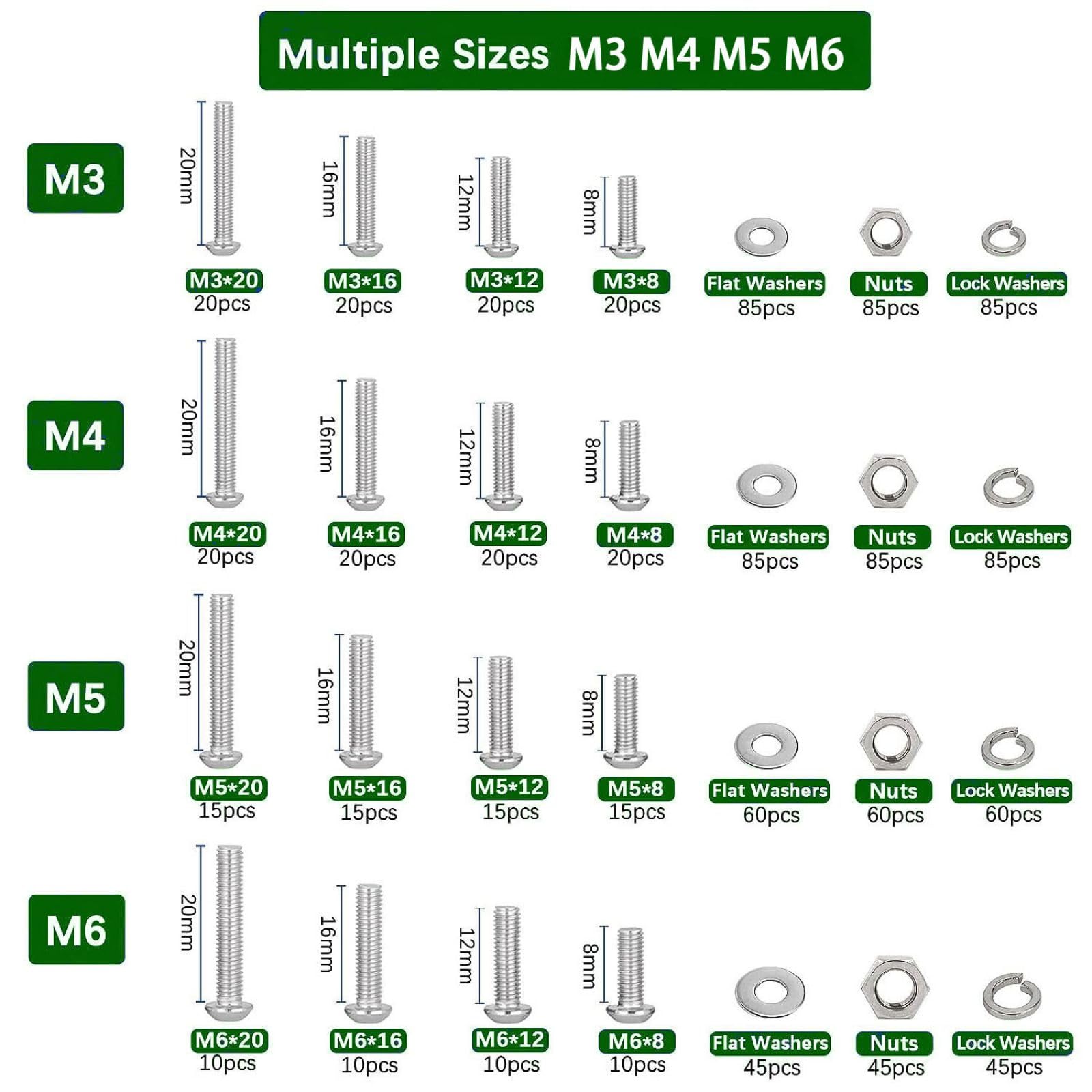

- Diameter: Referenced by numbers (e.g., #8, #10) or metric values (e.g., M4, M6).

- Length: Measured from under the head to the tip.

- Thread Pitch: Fine or coarse threads, depending on the application.

Use a Machine Screw Size Chart

Confused about SAE vs. metric measurements? Our machine screw size chart simplifies conversions. For example:

SAE SizeMetric EquivalentDiameter (inches)#8M40.164"#10M50.190"

Key Takeaway: A machine screw diameter chart ensures accuracy, especially for precision tasks like electronics or automotive repairs.

3. Types of Machine Screws and Their Uses

From pan head to hex head, the screw head type determines both function and aesthetics:

- Flat Head Machine Screws

- Hex Head Machine Screws

- Self-Tapping Machine Screws

Did You Know? Machine screw anchors are specialized screws used to secure objects to hollow walls like drywall.

4. Machine Screw vs. Bolt: What’s the Difference?

A common question we hear is: “Are machine screws and bolts the same?” The answer lies in their usage:

- Machine Screws: Require a nut or tapped hole and are generally smaller.

- Bolts: Larger, used with unthreaded holes and paired with nuts.

Example: Use stainless steel machine screws to attach a control panel to a metal frame. For assembling a structural beam, opt for bolts.

5. How to Measure Machine Screws

To determine the correct size:

- Measure the Diameter: Use a caliper on the threaded portion.

- Check the Length: Exclude the head in your measurement.

- Count Threads Per Inch (TPI): Use a thread gauge.

Quick Fix: If you don’t have tools, compare the screw to a machine screw dimensions chart for visual reference.

6. Where to Buy Machine Screws

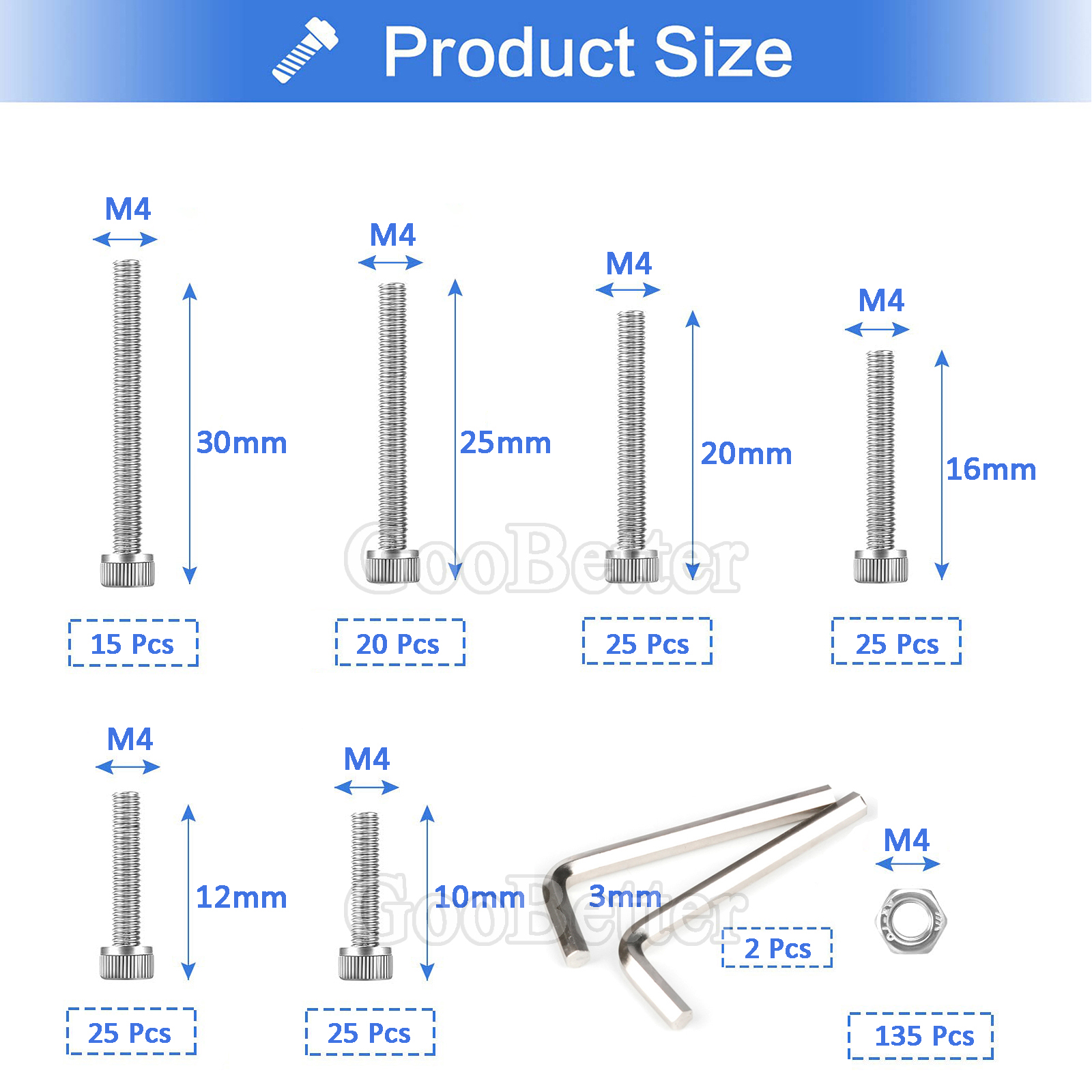

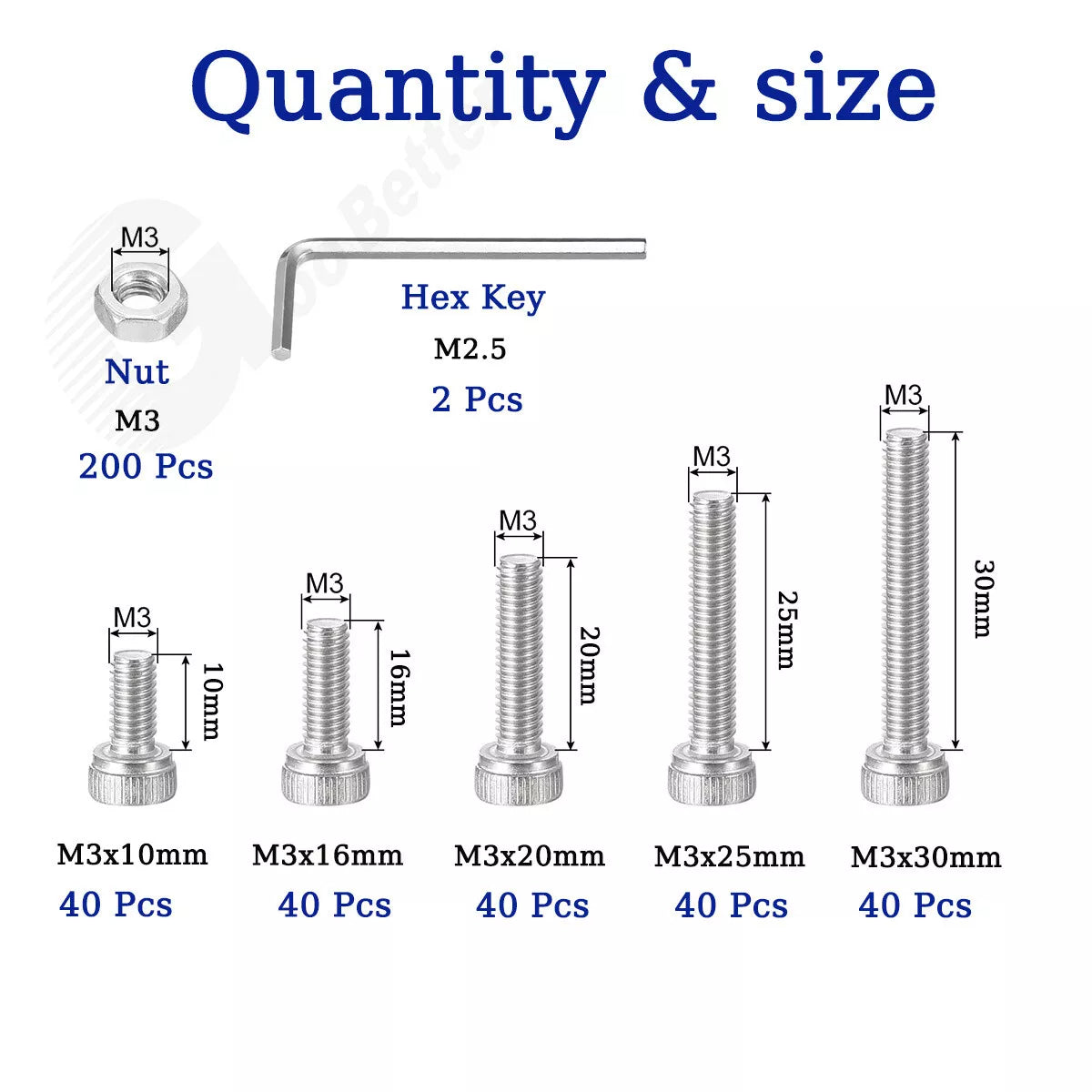

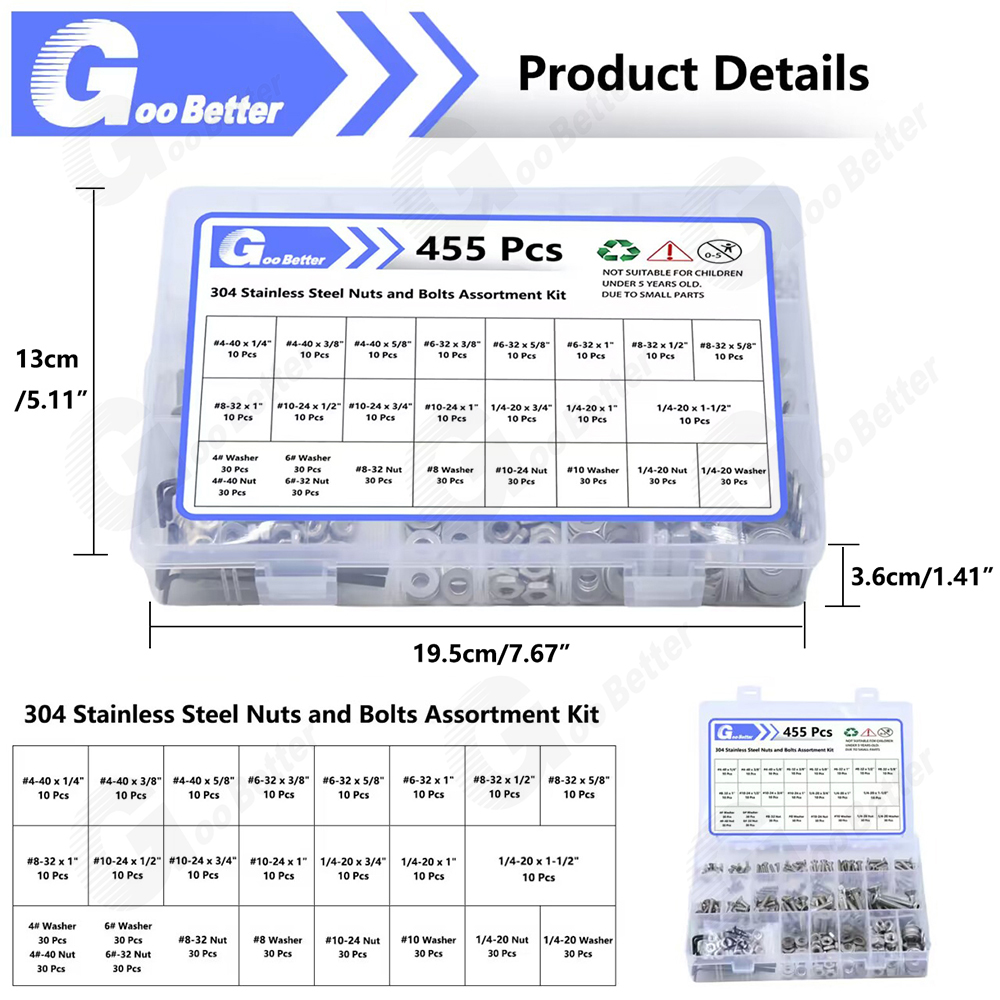

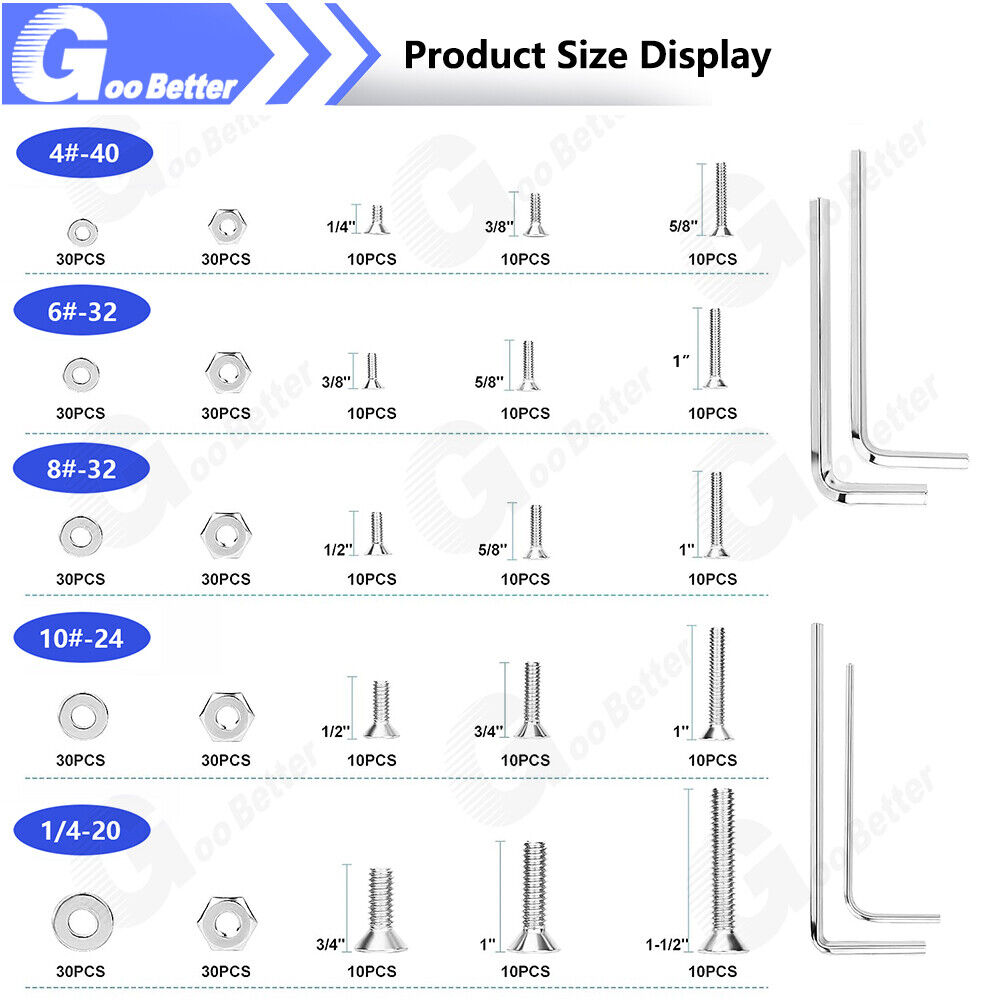

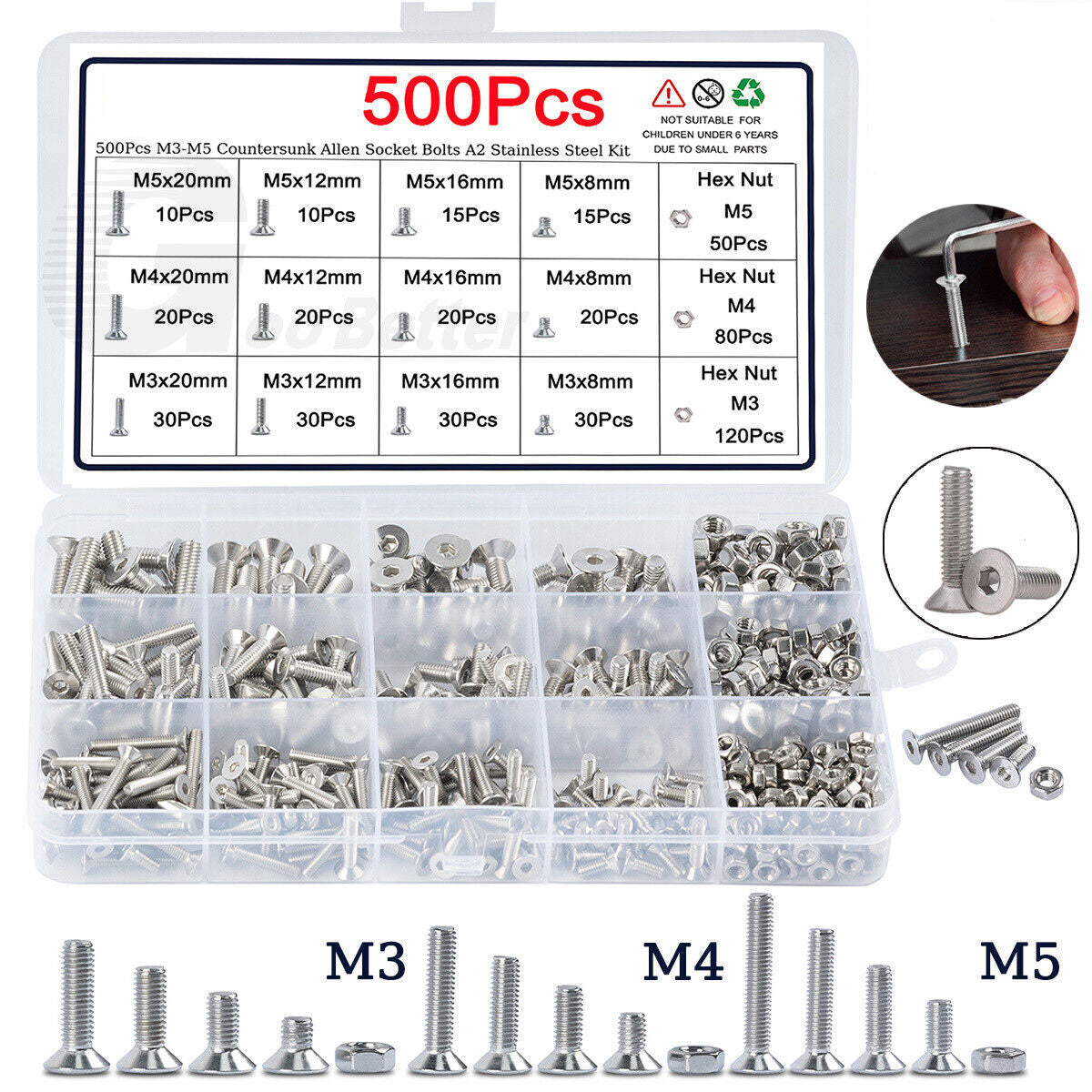

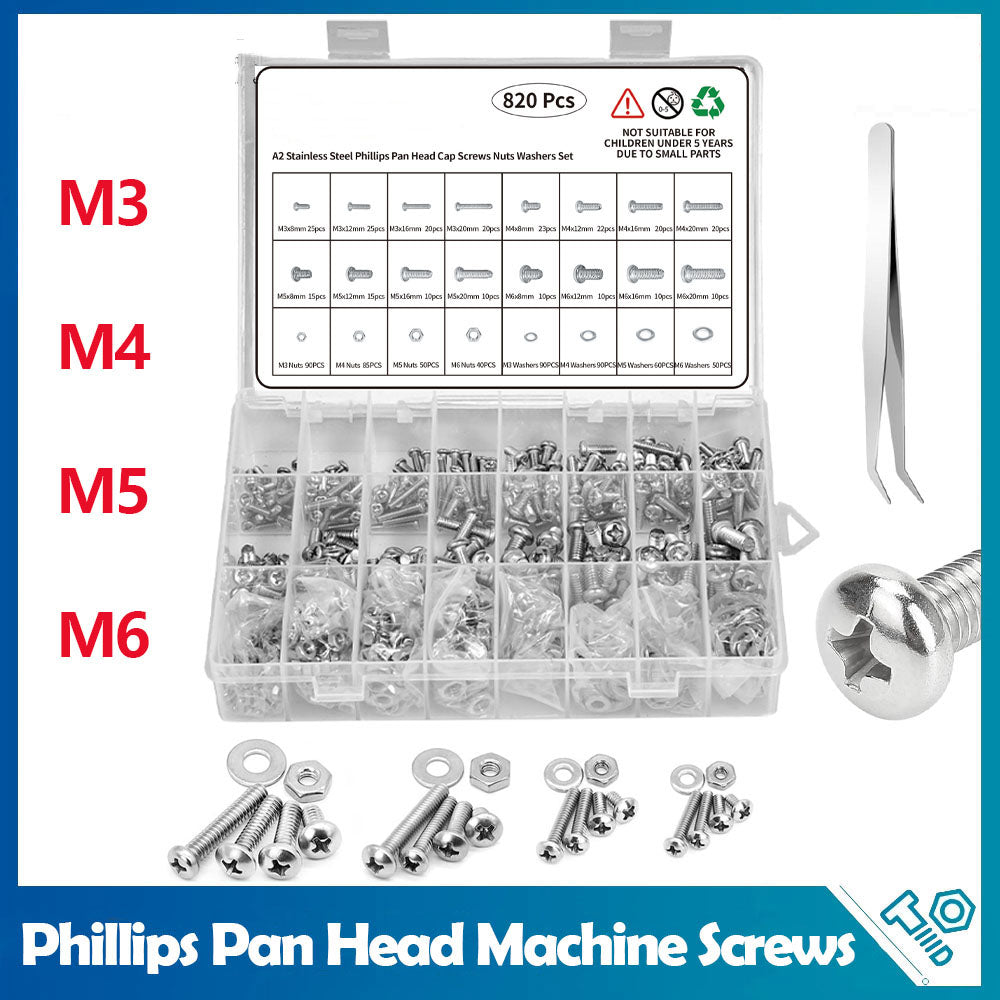

At HomeDIYer, we stock a wide range of machine screws, including:

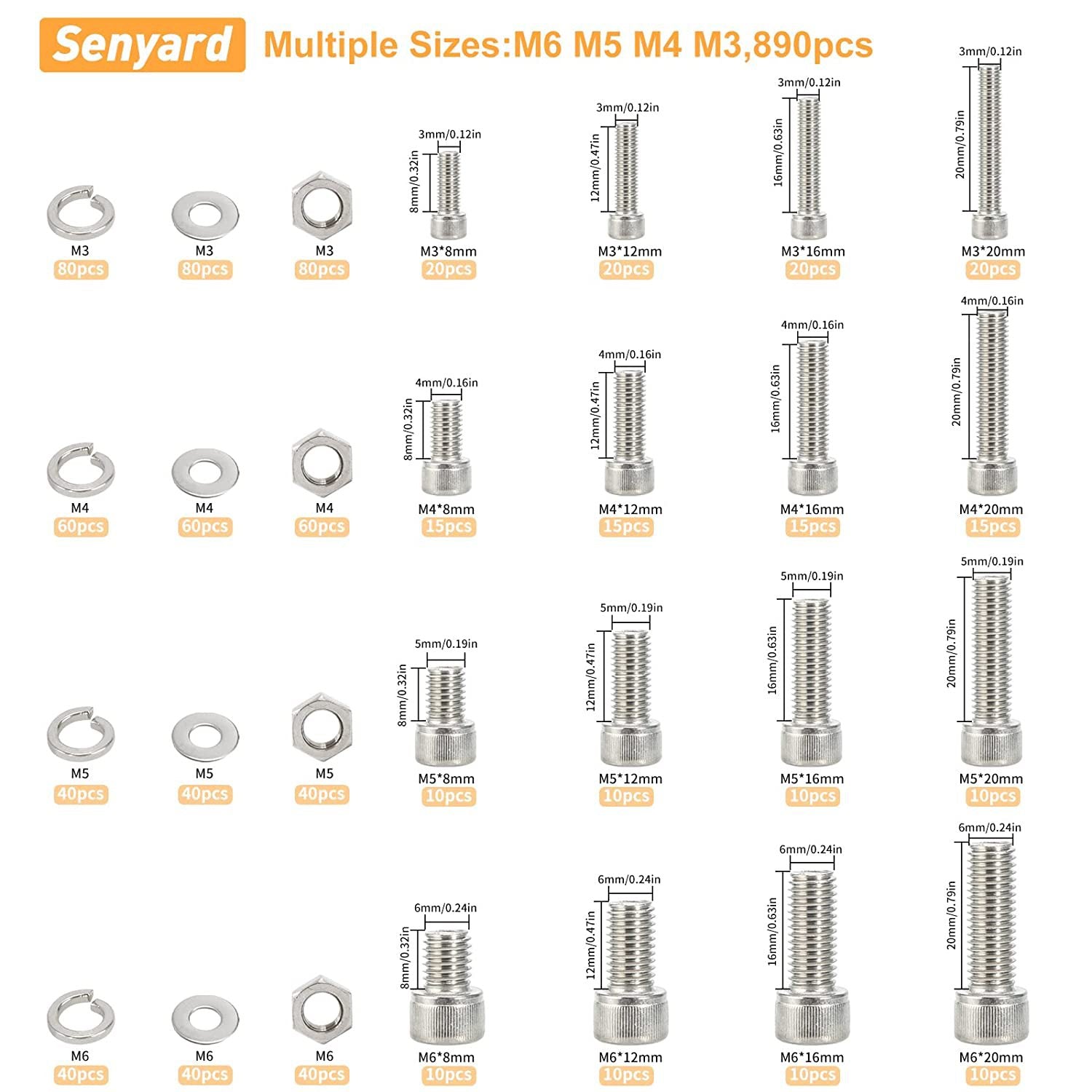

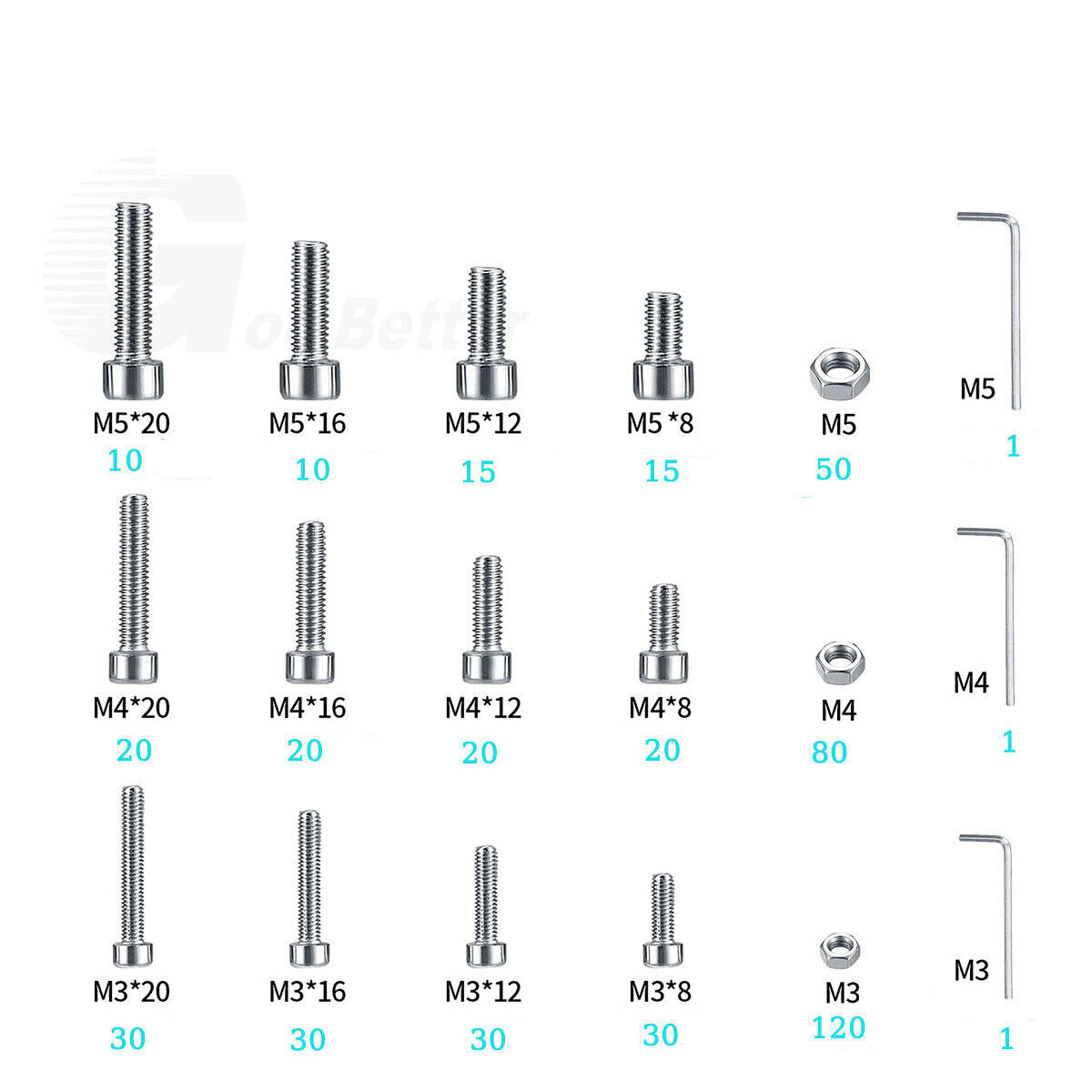

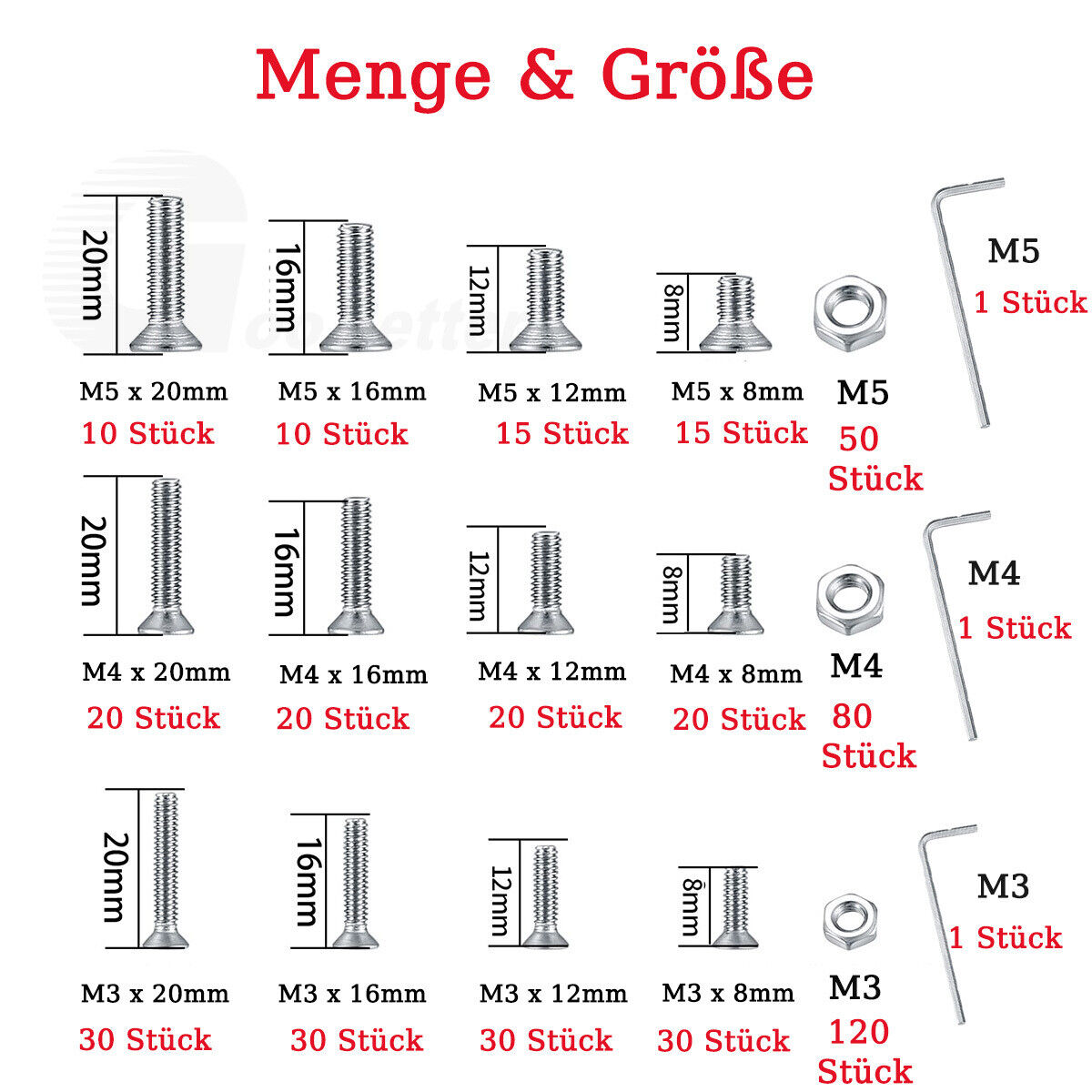

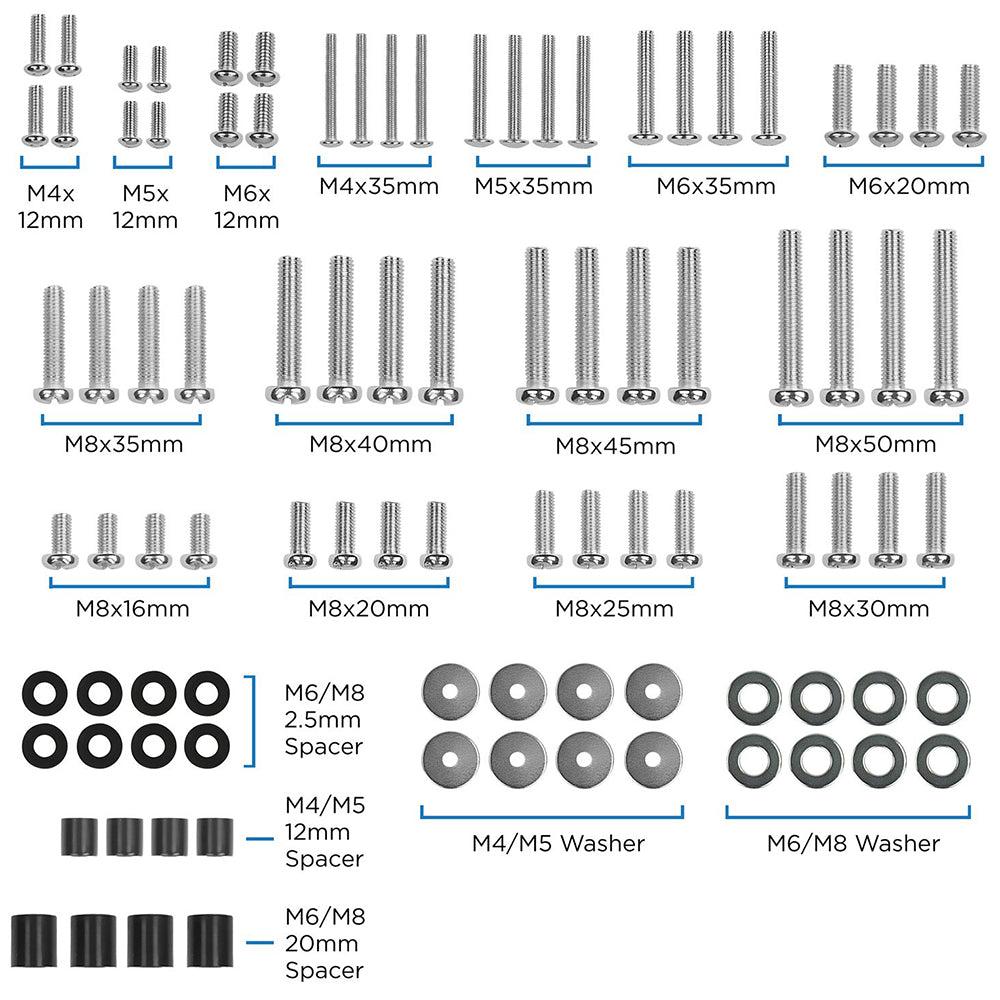

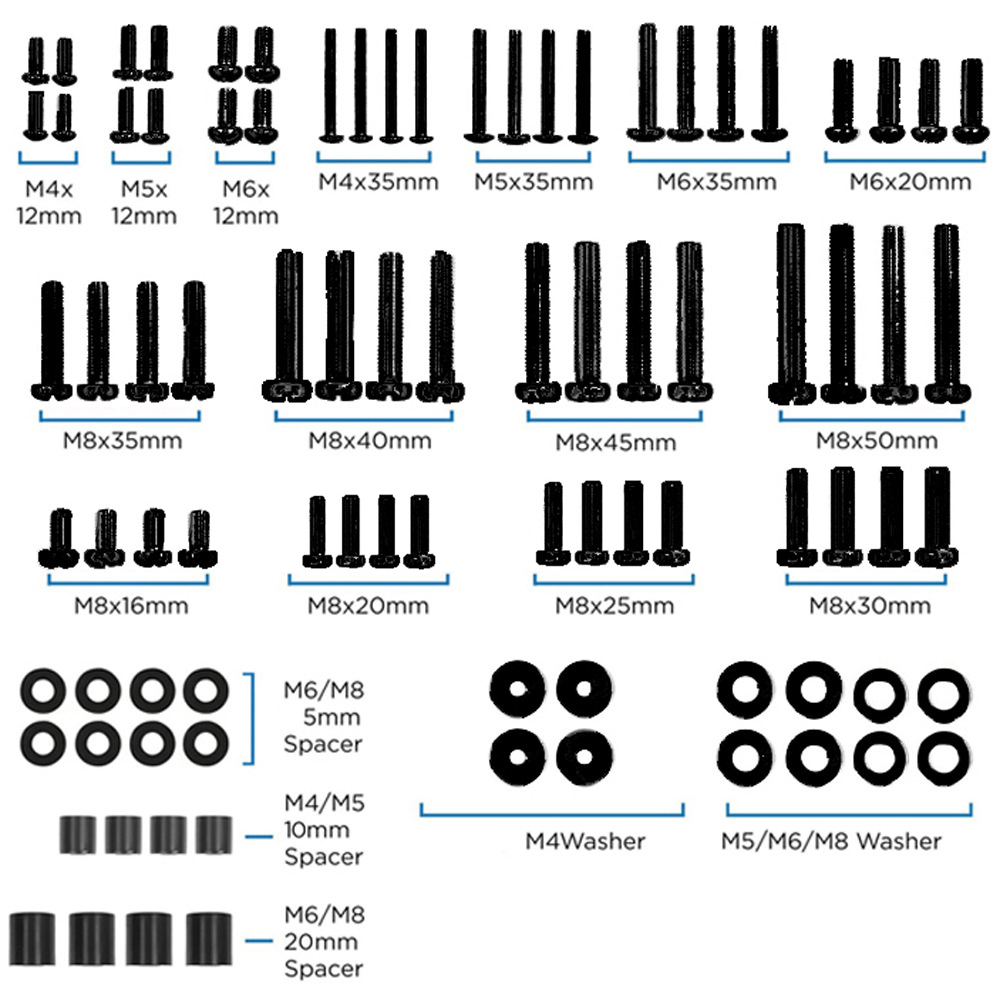

- Metric machine screws (M4, M6, M8)

- Hard-to-find sizes like 8-32 machine screws

- Bulk machine screw assortments for versatile projects

Local Options: Search for “machine screws near me” to find in-store pickup at hardware retailers.

7. FAQs About Machine Screws

Q: What’s the closest machine screw to 1/8 inch?

A: A #8 machine screw (0.164” diameter) is the nearest SAE size.

Q: Can I use machine screws in wood?

A: Yes, but pre-drill a pilot hole and pair with a nut for stability.

Q: How do I prevent rust on stainless steel machine screws?

A: Choose 316-grade stainless steel for maximum corrosion resistance.

Conclusion

Whether you’re a DIY beginner or a seasoned pro, mastering machine screw sizes, types, and applications will elevate your projects. Bookmark this guide for quick access to machine screw charts and expert tips. Ready to shop? Explore our collection of stainless steel, brass, and specialty machine screws at HomeDIYer.

How to Install Machine Screws

- Prepare the Threaded Hole: Ensure the hole is clean and matches the screw’s diameter.

- Align the Screw: Insert the screw into the hole or pair with a nut.

- Use the Right Tool: Drive with a screwdriver, hex key, or socket wrench depending on the head type.

- Tighten Securely: Apply steady pressure until snug, but avoid over-torquing.

- Pro Tip: Apply thread-locking fluid for vibration-prone applications.

Common Uses for Machine Screws

- Electronics Assembly: Secure circuit boards or device housings.

- Industrial Machinery: Fasten motor parts or conveyor systems.

- Automotive Engines: Attach sensors or brackets in tight spaces.

- DIY Furniture: Reinforce joints with hidden socket-head screws.