1. Product core introduction

HomeDIYer has always been committed to providing high-quality, precision-fit hardware accessories for home DIY enthusiasts, and this 304 stainless steel pan head machine screw is one of the professional-grade products we have carefully created.

The screws are precisely positioned in M8 size, with lengths ranging from 16mm to 20mm, which may seem like a relatively narrow range of options, but they are optimized for specific high-strength and high-stability DIY needs. Whether you are assembling industrial-style furniture, repairing and reinforcing machinery, or any other project with stringent screw specifications, we can provide you with a reliable fastening solution to help you turn your ideas into practical results.

We use top quality 304 stainless steel as raw material, combined with strict quality inspection process and exquisite processing technology, to ensure that each screw has excellent performance and reliable quality, and become a solid support for your home DIY projects.

2. The main characteristics of the product

High-quality 304 stainless steel material: 304 stainless steel is known for its excellent corrosion resistance, can effectively resist the erosion of moisture, acid and alkali and other harsh environments, even if the screws are exposed to long-term outdoor or wet indoor environments, but also maintain the structural integrity of the screws are not easy to rust, which greatly extends the service life of the product, provides your DIY works with long-lasting tightening force, reduces the cost of late maintenance and replacement frequency. Precise dimension tolerance: adopting advanced technology, the screws are made of high quality materials.

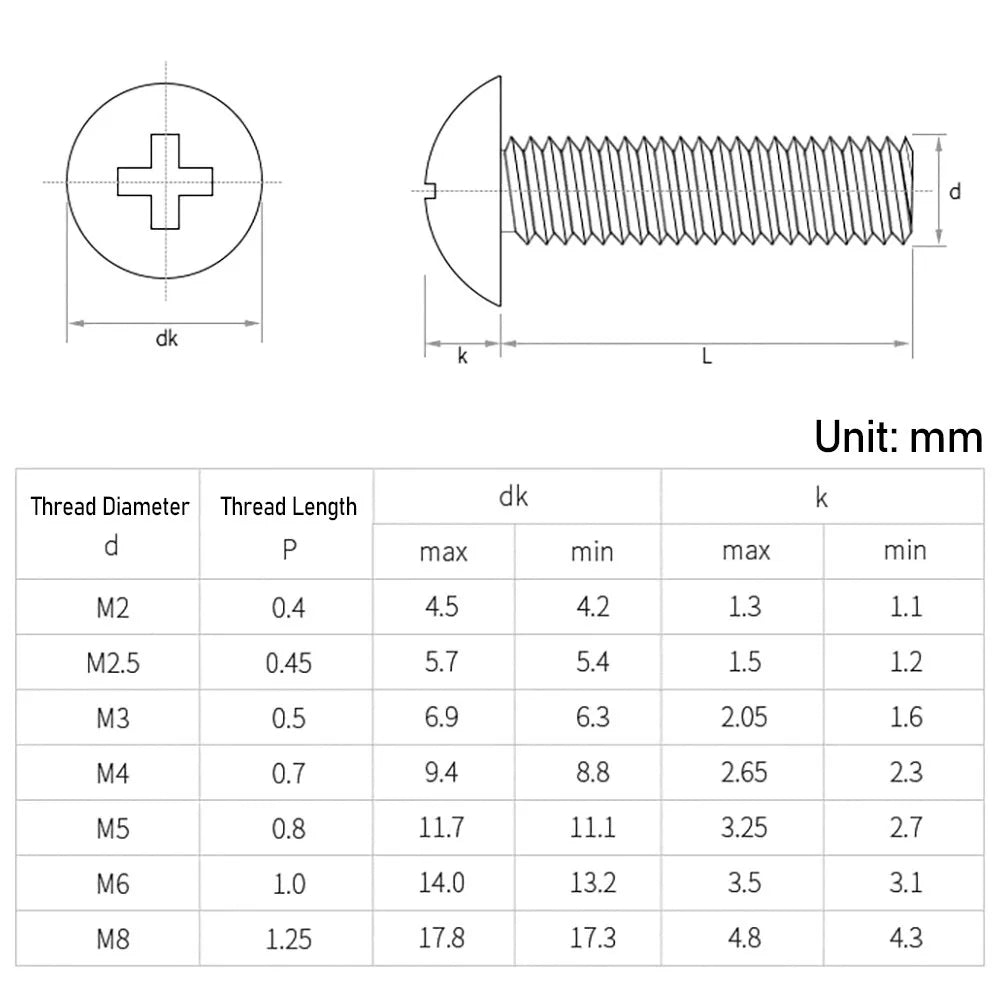

Precise dimensional tolerances: using advanced production equipment and precision manufacturing process to ensure that the dimensional tolerances of M8 diameter and 16mm - 20mm length are controlled within a very small range, and the matching precision with other supporting components is extremely high, strong stability after installation, able to withstand greater tension and pressure, effectively preventing loosening and displacement, to ensure the safety and reliability of your DIY projects, to ensure the structure of the tight connection and the overall stability of the product. Stability.

Advantage of plum groove design: The unique design of plum groove, compared with the traditional cross slot or one-slot, the contact between the screwdriver and the groove is more compact and stable, which can provide greater torque transmission and effectively prevent slipping phenomenon, so that the installation and removal of screws is easier and more convenient. Even in the case of requiring a larger tightening force, it can ensure the accuracy and efficiency of the operation, so that you can be more comfortable in the DIY process and improve work efficiency.

Plate head modeling features: plate head design is not only beautiful and generous, but also with a larger contact area with the fixed parts, can disperse the pressure, reduce the damage to the surface of the material, and at the same time in some application scenarios that need to withstand a large tensile force or pressure, the plate head can provide better support and stability, to ensure that the tightening effect is more reliable, so as to make your DIY projects more durable and to enhance the overall structure of the stability and safety. safety.

3. Product use scene

Industrial Style Furniture Making: For DIY enthusiasts who pursue individuality and fashion, making industrial style furniture is a popular choice. This M8 size stainless steel pan head machine screws perfectly fits the hard style of industrial style. It can be used to assemble metal pipes and wooden desktops, metal frames and shelves, etc. Its longer 20mm length ensures sufficient fastening force when connecting thick materials to create unique and attractive industrial style desks, coffee tables, shelves and other furniture, adding a rough and delicate aesthetic to the home environment, showing your unique taste and creative talent.

Mechanical Equipment Repair and Reinforcement: These M8 stainless steel screws can play an important role in repairing or reinforcing some mechanical equipment at home (such as small treadmills, electric fans, bicycles, etc.). They can replace existing damaged screws or provide additional tightening force to ensure that critical parts of the equipment are securely attached. For example, when repairing a treadmill bracket, the 16mm - 20mm length can penetrate the metal parts and secure them tightly, restoring the equipment to its normal operating condition and extending its service life, as well as saving you money on repairs and ensuring the safe use of the equipment.

Heavy DIY project support structure: In some DIY projects that need to withstand a lot of weight or pressure, such as building a small outdoor storage shed, making your own indoor heavy-duty shelves, etc., M8 size screws can provide enough strength and stability. The shorter 16mm length can be used to fix the shelves and frames of the shelves to ensure the stability of the internal structure, while the 20mm length can be used to fix the shelves to the wall or the floor, providing all-around stable support, so that your DIY projects can withstand heavier items to meet the actual needs of use.

4. Product use instructions

Preparation of tools: Make sure to choose the screwdriver with the specifications of M8 screws, and make sure that the size and shape of the screwdriver bit fits the screw's socket precisely, so as to avoid slipping when screwing the screws, damaging the screws and the screwdriver bit, and to ensure the smooth operation of the screws.

Preparation before installation: Before installing the screws, carefully clean the surface of the parts to be fixed, remove dust, oil, rust and other impurities to ensure that the screws and parts can be in close contact with each other to obtain the best friction and fastening effect. For harder metal materials or parts that need to withstand greater pressure, it is recommended to pre-drill pilot holes slightly smaller than the diameter of the M8 screws using a suitable drill bit, which will help the screws screw in more easily, while minimizing the risk of damage to the material, ensuring a smooth installation process, and improving the accuracy and stability of the installation.

Installation process: Align the screws with the pre-drilled holes (if any) or directly with the position where they need to be secured, then insert the plumb bob screwdriver vertically into the plumb bob slot of the screws and slowly start to unscrew the screwdriver so that the screws initially enter into the holes. At the initial stage of screwing in, gently apply force to ensure that the screw can enter vertically and smoothly, avoid tilting or twisting. As the screw gradually enters, gradually increase the rotational force, but be careful to maintain an even application of force to prevent damage to the screw threads or cracking of the fixed parts due to excessive force. If in the screwing process encountered greater resistance, you can pause appropriately to check whether the screw is vertical and whether there are foreign objects in the hole blocking, if necessary, you can use a small amount of lubricant coated in the screw threads, but be careful to avoid lubricant contamination of other parts or affect the tightening effect, to ensure that the screws can be securely mounted in place, to achieve the desired effect of fastening.

Removal Procedure: If you need to remove an installed M8 screw, first insert a suitable plunge screwdriver into the plunge slot of the screw, making sure that the tip of the cutter fits tightly into the slot. Then, slowly rotate the screwdriver counterclockwise to loosen the screw gradually. During the loosening process, keep the screwdriver vertical to prevent slippage. If the screw has not been disassembled for a long time or affected by other factors and become more tight, you can first drop the appropriate amount of rust remover or lubricant around the screw, wait for a period of time, so that the lubricant is fully penetrated, and then try to unscrew the screw, which can greatly reduce the difficulty of disassembly, and at the same time to protect the screws and the threads of the parts being fixed from damage, so as to facilitate the subsequent adjustments or maintenance work you carry out.