Set Screws Collection at HomeDIYer

Secure your projects with HomeDIYer’s Set Screws Collection. Whether you’re fixing a door handle, assembling machinery, or repairing a shower fixture, our set screws are designed for precision and durability. Choose from stainless steel set screws for corrosion resistance, metric set screws for international standards, or specialized cup point set screws for heavy-duty applications.Self-Drilling Design

Sharp drill points eliminate pre-drilling needs, saving 50% installation time on metal/wood surfaces

Corrosion-Resistant

Zinc-plated & stainless steel options with rust-proof coating for outdoor applications

Enhanced Grip

Dual-thread design provides 30% better holding power compared to standard screws

Recommended Product Category

Homediyer’s drilling screws are engineered for effortless installation in metal, wood, and masonry. Featuring a self-drilling tip, these screws eliminate the need for pre-drilling, saving time and effort. Choose from stainless steel or zinc-plated finishes for corrosion resistance. Ideal for roofing, framing, and HVAC applications.

- Materials: Stainless steel, zinc-plated, carbon steel

- Types: Hex head, Phillips, flat head

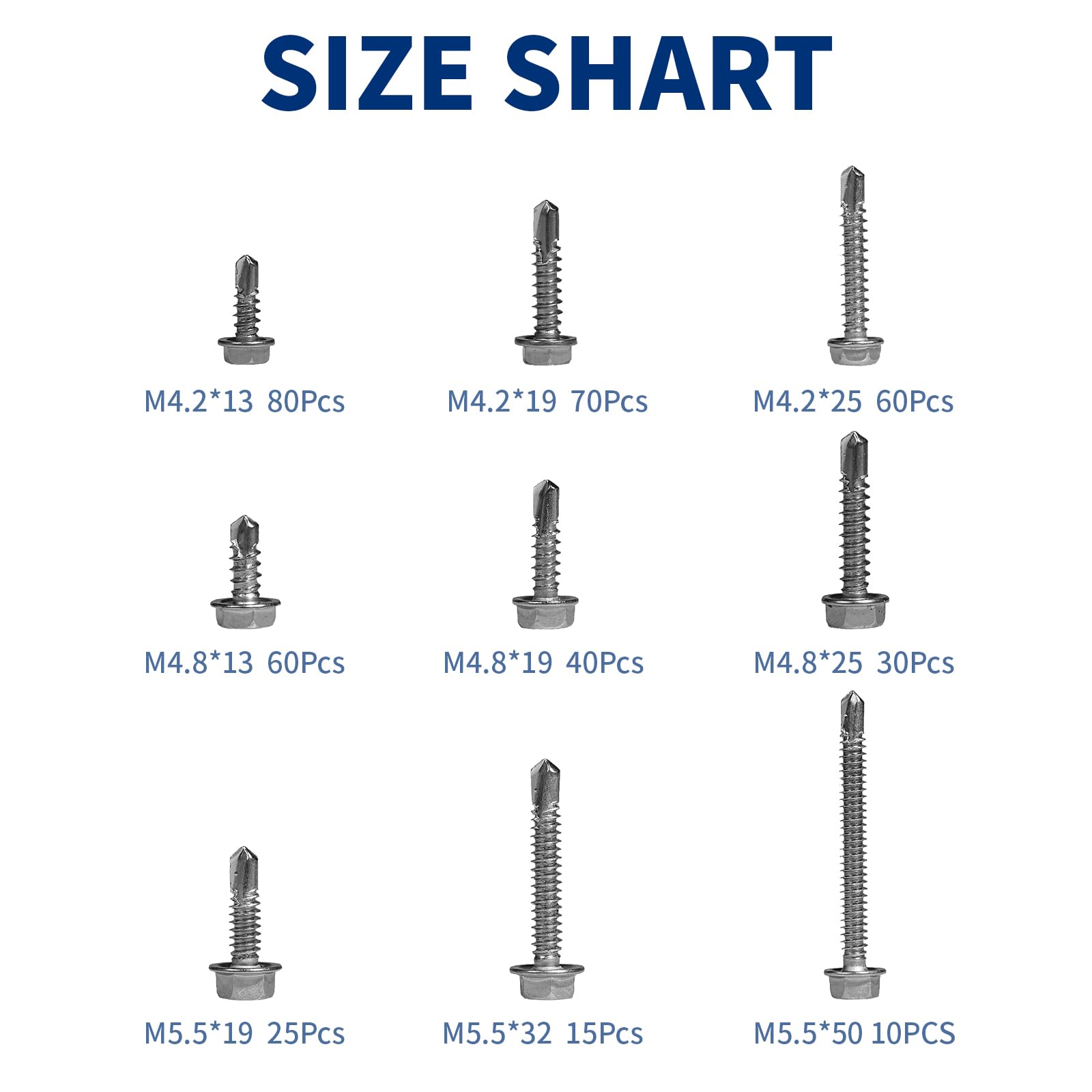

- Sizes: #8 to #14, lengths ½” to 3”

- Features: Anti-rust coating, self-tapping threads, sharp drill points

The Complete Guide to Set Screws: Types, Sizes, and Removal Tips

Set screws are small but mighty fasteners used to secure components in place without protruding heads. From door handle set screws to allen set screws in machinery, they’re essential for both DIYers and professionals. However, choosing the wrong size or type—or dealing with a stripped screw—can turn a simple task into a headache. This guide covers everything you need to know, including how to select the right set screw and troubleshoot common issues.

1. What Are Set Screws?

Set screws are headless fasteners designed to hold parts in place by applying pressure against a surface. Key features include:

- Headless Design: Flush installation for unobstructed machinery or furniture.

- Drive Types: Allen (hex), Torx, or slotted drives for tool compatibility.

- Tip Styles: Cup point, flat point, or dog point for different grip strengths.

Common Uses:

- Securing door handles or shower fixtures.

- Locking pulleys, gears, or shafts in machinery.

- Fastening collars or couplings in automotive parts.

Pro Tip: For high-vibration environments, use dog point set screws with a detent tip to prevent loosening.

2. Types of Set Screws and Their Uses

Allen Set Screws (Hex Drive)

- Best For: Machinery, automotive, and furniture.

- Example: M3 set screws for small electronics or M6 set screws for heavy equipment.

Cup Point Set Screws

- Best For: Permanent installations (e.g., shaft collars).

- Example: Creates a dimple in the shaft for a secure grip.

Stainless Steel Set Screws

- Best For: Outdoor or corrosive environments (e.g., marine applications).

Metric Set Screws

- Best For: International projects requiring ISO standards.

3. How to Choose the Right Set Screw

Follow these steps to avoid stripped threads or poor performance:

- Material Compatibility

- Size and Thread Pitch

- Tip Style

Quick Reference: Use a set screw size chart to match screw dimensions to your project.

4. How to Remove a Stripped Set Screw

Stripped screws are a common frustration. Here’s how to tackle them:

- Use a Screw Extractor Set

- Apply Heat

- Lubricate

Pro Tip: For delta shower handle set screws, avoid over-tightening to prevent stripping.

5. FAQs About Set Screws

Q: What’s the difference between a grub screw and a set screw?

A: They’re often used interchangeably, but grub screws typically have a blunt tip.

Q: How to find set screws near me?

A: Search for “set screws Home Depot” or shop our Set Screws Collection online.

Q: Can I reuse set screws?

A: Yes, but inspect threads for wear. Replace if damaged.

Q: What size set screw for a door handle?

A: Most door handles use #8-32 or M4 set screws.

6. Where to Buy Set Screws

At HomeDIYer, we offer:

- Stainless steel set screws (indoor/outdoor use).

- Metric set screw assortments (M3 to M12).

- Specialty screws like cup point or dog point set screws.

Local Retailers: Find set screws at Ace Hardware or Lowe’s for urgent needs.

Conclusion

Whether you’re fixing a door knob set screw or securing industrial machinery, choosing the right set screw—like stainless steel set screws for durability or allen set screws for precision—ensures a secure, long-lasting hold. For stubborn screws, a screw extractor set can save the day. Explore our Set Screws Collection for high-quality options and expert support.

How to Use Drilling Screws

- Select the Right Screw: Match screw length/diameter to material thickness.

- Prepare the Surface: Clean debris from the drilling area.

- Align the Screw: Position perpendicular to the surface.

- Drive the Screw: Use a drill/driver at medium speed. Apply steady pressure until the head sits flush.

- Safety Tip: Wear goggles to protect against metal/wood splinters.

Where to Use Drilling Screws

- Metal Roofing: Secure sheets without pre-drilling.

- Wooden Decks: Attach joists with corrosion-resistant screws.

- Drywall to Metal Studs: Self-drilling tips simplify installation.

- DIY Furniture: Assemble frames with flush-finish heads.