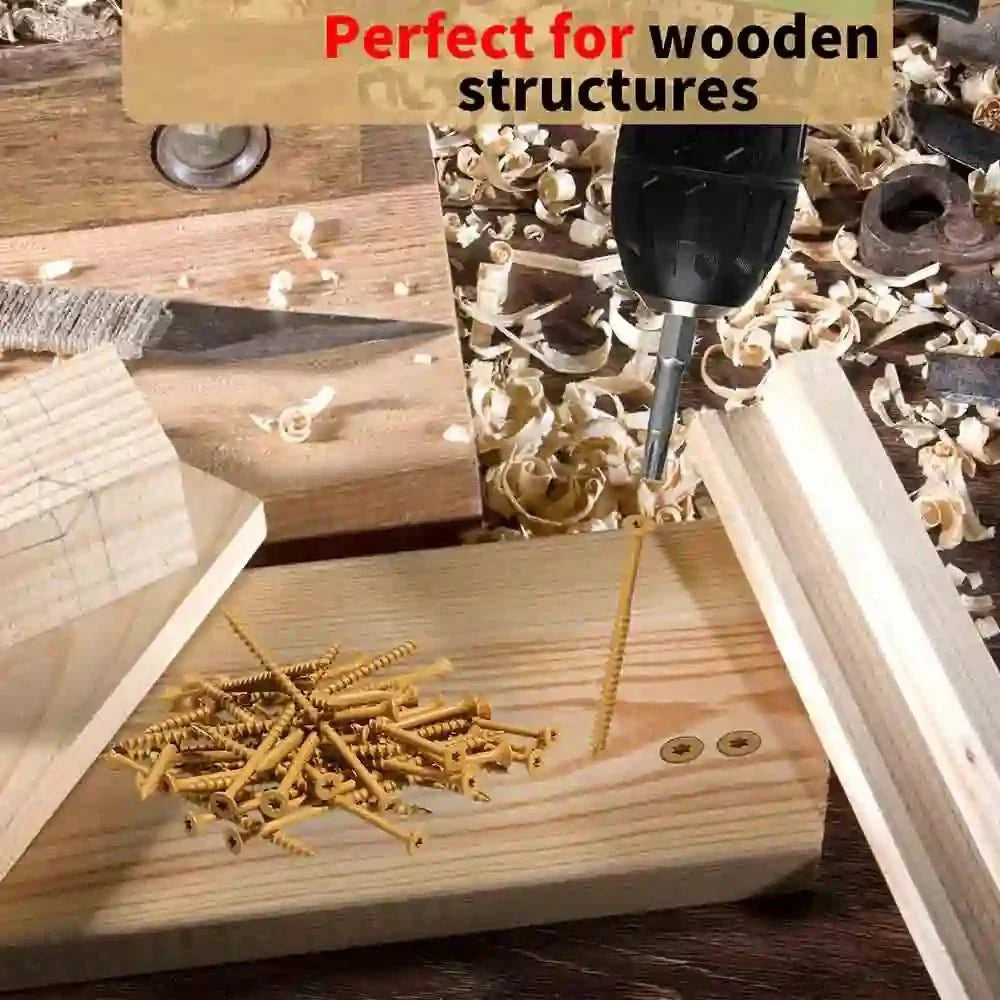

Picture this: You’re building a backyard deck in Texas heat, assembling IKEA furniture in a New York apartment, or crafting a barn door for your Midwest farmhouse. Suddenly—crack. A screw splits the wood, strips its head, or snaps under pressure. Sound familiar? Choosing the right screw for wood isn’t just about finishing your project—it’s about avoiding costly mistakes and safety hazards. Let’s cut through the confusion and find the perfect fastener for your needs.

Why "Generic" Screws Fail American Woodworkers

Most hardware-store bargain bins are filled with drywall or sheet metal screws—not true wood screws. These lack critical features for gripping wood fibers, leading to:

-

Splitting (especially in oak, maple, or pressure-treated pine).

-

Stripped heads (thanks to cheap Phillips drives).

-

Rust stains on your cedar deck or white-painted shiplap.

Pro Tip: If you’ve ever bought screws from a big-box store’s "assorted hardware" aisle, you’ve likely faced these issues.

The American Standard: 5 Must-Have Features of Wood Screws

-

Coarse, Deep Threads

-

Bites aggressively into Southern yellow pine, Douglas fir, and other common US lumber.

-

Avoid: Fine-threaded "all-purpose" screws (they’re for metal!).

-

-

Sharp, Self-Tapping Tip

-

Crucial for dense hardwoods (like hickory) or resinous pressure-treated wood.

-

No more pre-drilling 200 holes for a fence!

-

-

Unthreaded Shank

-

Pulls wood pieces tightly together (e.g., face-framing cabinets or table legs).

-

Fun Fact: This design originated in 19th-century American furniture factories.

-

-

Torx (Star) or Square Drive

-

Phillips = strip city. Torx/Square = no-cam-out perfection.

-

Why Americans love it: Works flawlessly with impact drivers (our #1 tool).

-

-

Corrosion Resistance

-

Outdoor projects (decks, fences): Stainless steel or ceramic-coated deck screws (look for "triple-coated" brands like GRK or TimberLOK).

-

Indoor/humid areas: Zinc-plated or brass wood screws.

-

Avoid: Plain steel screws—they’ll stain cedar decks and teak furniture.

-

Top 5 Wood Screws Americans Actually Use

-

Deck Screws

-

Best for: Pressure-treated lumber, composite decking, pergolas.

-

Key Features: Self-countersinking head, star drive, corrosion-proof coating.

-

-

Pocket-Hole Screws

-

Best for: DIY furniture, cabinet face frames, hidden joints.

-

Why Americans swear by them: Kreg Jig compatibility (a garage staple).

-

-

Construction Screws

-

Best for: Framing, subfloors, sheathing.

-

Look for: #9 or #10 gauge, 2–3" length, Phillips-drive alternatives.

-

-

Trim Head Screws

-

Best for: Crown molding, baseboards, delicate crafts.

-

Pro Secret: Use with filler putty for invisible finishes.

-

-

Specialty Woodworking Screws

-

Best for: Fine furniture, cutting boards, heirloom projects.

-

American-Made Gems: Hillman brass screws, Spax multi-material designs.

-

Real Talk: 3 US-Specific Buying Tips

-

"Pressure-Treated" = Must Use Stainless or Coated

-

The chemicals in PT lumber (ACQ, MCQ) corrode plain steel fast. Save your deck!

-

-

Length Matters

-

General rule: Screw should penetrate the bottom board by 1" (e.g., 1.5" screw for ¾" boards).

-

-

Skip the Phillips

-

Torx (T25) or Square (SQ2) drives dominate pro job sites. Worth the extra $0.50 per box.

-

When to Pre-Drill (The American Way)

-

ALWAYS: Hardwoods (oak, walnut), near edges, or screws thicker than #8.

-

NEVER: Softwoods (pine, cedar) with self-drilling deck screws.

-

Tool Tip: Use DeWalt or Milwaukee combination pilot/countersink bits.

The Bottom Line

Whether you’re building a California redwood hot tub, a Florida pool enclosure, or a Vermont barn door—don’t gamble with generic screws. True wood screws, deck screws, and woodworking screws are engineered for your project’s safety, beauty, and longevity.

→ Ready to Build Like a Pro?

At HomeDIYer, we stock 100% American-compatible screws:

-

🇺🇸 Deck screws that laugh at rain, snow, and BBQ spills.

-

🔨 Pocket-hole screws for Kreg Jig warriors.

-

🪵 Fine woodworking screws for heirloom creations.

Shop Our Bestselling Wood Screws Now →