1. Product core introduction

HomeDIYer 304 Stainless Steel Square Angled Washers in sizes ranging from M6 to M30 are made from durable 304 stainless steel and are designed to provide excellent support and levelling capabilities, making them ideal for a wide range of applications where precise alignment and stability are critical. Whether it's a DIY project or an industrial installation, rely on our square mitre washers to get the job done right.

2. The main characteristics of the product

High-quality 304 stainless steel material: 304 stainless steel is selected, which has good corrosion resistance, can maintain stable performance in humid, acid and alkali and other harsh environments, not easy to rust, effectively extend the service life, suitable for outdoor facilities, marine engineering, chemical equipment and other occasions with high requirements for rust prevention, to ensure that the connection parts of the long term reliability, reduce maintenance costs and failure of the connection due to rust, and at the same time, ensure the It also ensures the safety and stability of the product in various environments.

Precise square bevelling design: The unique square bevelling structure enables it to provide precise angle adjustment when connecting, effectively compensating for the non-parallelism between the connected parts, ensuring that the connecting surfaces are closely fitted and the pressure is evenly distributed, improving the stability and reliability of the connection, which is suitable for occasions requiring high installation precision, such as the installation of machinery and equipment, and the erection of steel structures.

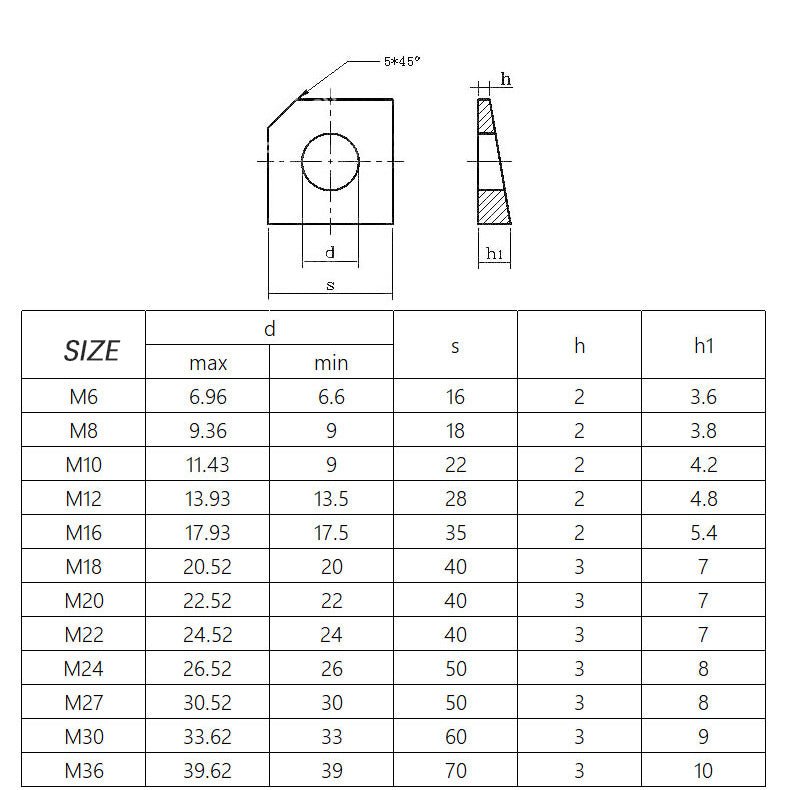

Wide range of sizes: Provide a wide range of sizes from M6 to M30 to meet the needs of different hole diameters and application scenarios, whether it is a small precision instrument or a large industrial equipment, you can find the right washer specifications, to ensure that it accurately matches with a variety of standard bolts and nuts, to achieve accurate and efficient connections, providing users with a wider range of application options, and facilitating the user to select the type according to the actual needs.

Good surface treatment: the surface of the washer is finely treated, smooth and flat, without burrs, cracks and other defects, which is not only aesthetically pleasing, but also reduces the wear and tear on other parts during the installation process, and also helps to improve the friction between the washer and the connected parts, which further enhances the stability and reliability of the connection.

3. Product use scene

DIY and home decoration: In home DIY projects, such as building wooden furniture, installing metal doors and windows, fixing electrical equipment, etc., it can be used to adjust the level and verticality of the connecting parts to ensure a solid structure of the furniture, smooth opening and closing of doors and windows, and smooth installation of electrical appliances, so as to improve the quality and safety of the DIY works; in home decoration, it is used for fixing handrails on the staircases, installing chandeliers, and assembling sanitary ware facilities. It can effectively solve the problems caused by uneven installation surface, make the home environment more beautiful and comfortable, and also enhance the stability and durability of home facilities.

Automotive maintenance and modification: In automotive maintenance, it is used for the installation and adjustment of engine, transmission, chassis and other components, which can compensate for the manufacturing tolerances and wear between components, ensure that the connection between components is tight and precisely aligned, and improve the performance and safety of the car; in the field of automotive modification, such as the installation of modified wheels, suspension upgrades, etc., the square bevelled washer can be used to optimize the angle of the components and the position of the installation. In the field of automobile modification, such as the installation of modified wheels, suspension upgrading, etc., square bevel washers can be used to optimise the installation angle and position of components, improve the handling performance and appearance of the car, and satisfy the needs of car owners for personalisation and high performance.

Industry and manufacturing: In industrial production, they are widely used in the manufacture and assembly of various mechanical equipment, such as machine tools, engineering machinery, power equipment and other fields. In the installation and debugging of machine tools, square inclined washers are used to adjust the level and precision of machine tools to ensure the machining accuracy and stability of machine tools; in the manufacture of engineering machinery, they are used for connecting large structural parts, which can effectively disperse the pressure and improve the load-bearing capacity and reliability of the structure; in the installation of electric power equipment, they are used to ensure the smooth installation of transformers, distribution cabinets, etc., and to guarantee the normal operation of the electric power system, which provides a strong support for the industrial Manufacturing development to provide strong support.

4. Product use instructions

Preparation before installation:

Check the appearance of the gasket for cracks, deformations, burrs and other defects to ensure that the product quality is intact. Also check whether the required specification matches the actual application scenario, and replace it in time if there is any problem, so as not to affect the installation effect and use performance.

According to the hole diameter of the connected parts and bolt specifications, select the appropriate 304 stainless steel square inclined washers specifications, and prepare the corresponding installation tools, such as spanners, screwdrivers, levels, etc. (according to the specific installation scenarios), to ensure that the tools are clean, sharp and functioning properly, so as to avoid damage to the washers or the connected parts in the installation process.

Use a cleaning cloth or appropriate solvent to clean the surface of the connected parts and bolt threads, remove oil, rust, dust and other impurities, and ensure that the surface is dry, flat and smooth, so as to ensure that the gasket can fit closely, achieve good support and levelling effect, and improve the stability and reliability of the connection.

Installation steps:

Place the square bevelled washers on the bolt holes of the connected parts, adjust the direction of the washers as needed so that the bevelled angle can effectively compensate for the non-parallelism of the connection surface.

Insert the bolt and screw on the nut, use appropriate tools to tighten the nut gradually according to the specified tightening torque, in the process of tightening, pay attention to keep the bolt vertical, avoid skewing, and at the same time, use the level meter and other tools to check the level and perpendicularity of the parts to be connected, according to the actual situation of the fine-tuning of the position and angle of the washer, to ensure that the connecting surface is closely adhered to the uniform distribution of pressure.

After tightening is completed, carry out a comprehensive inspection of the connection parts to see whether the washers are installed in place, whether the connected parts reach the expected level and verticality, whether the nuts or bolts are tightened securely, and whether there are any signs of loosening. If necessary, the tightening torque can be checked again and the connected parts can be marked appropriately for subsequent periodic inspection and maintenance.