1. Product core introduction

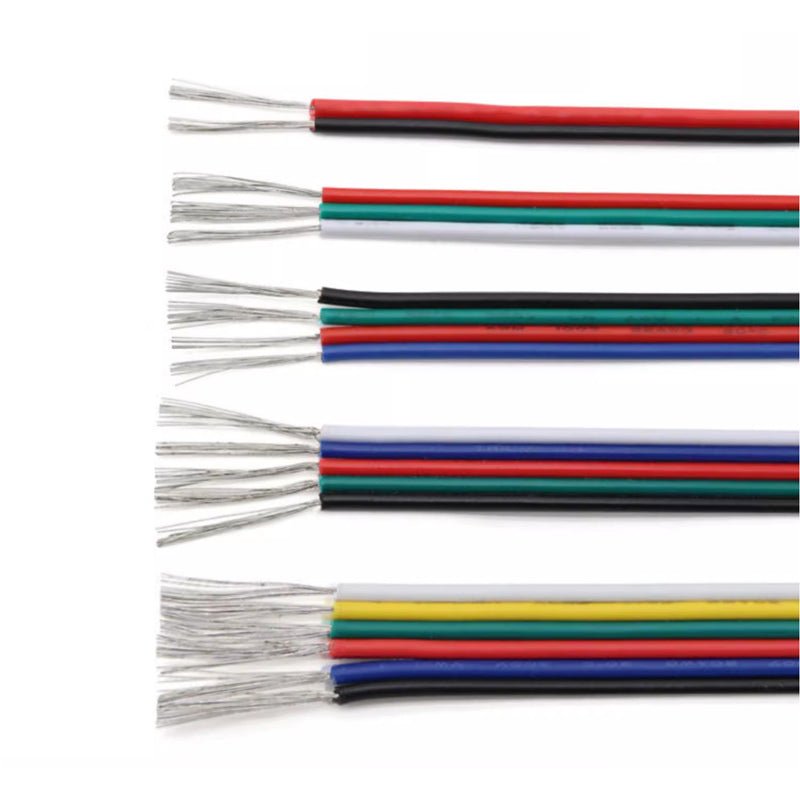

This Flat Ribbon Cable LED Connector Hookup Cable is a high quality product specially designed to meet the needs of modern lighting and electronic equipment connection. Made of flexible PVC with 18/20/22AWG options, it is designed to provide a reliable, convenient and efficient solution for internal and external connections of various LED lighting systems and electronic devices.

2. The main characteristics of the product

High quality flexible PVC material:

High-quality flexible PVC is chosen as the insulation layer and jacket material, which has good flexibility and abrasion resistance, and can be used stably for a long time under different environmental conditions.

PVC material also has good insulating properties, can effectively isolate the current, prevent the occurrence of leakage phenomenon, to protect the electrical safety in the process of use, so that you do not worry.

Precise AWG specification:

Provide 18/20/22AWG three kinds of specifications, each specification corresponds to a specific wire diameter and electrical performance parameters. Users can accurately select the appropriate AWG gauge according to the current carrying requirements, signal transmission requirements and equipment compatibility in actual applications, ensuring that the cable meets the performance requirements without wasting resources or over-performance, and achieving the best price/performance ratio and system performance optimisation.

Flat Ribbon Design:

The unique flat ribbon structure provides higher space utilisation and better heat dissipation than traditional round cables. In the narrow space wiring more convenient and fast, can effectively reduce the cable space, make the wiring more neat and beautiful, especially for the space requirements of the electronic equipment internal connection and some compact lighting installation scenarios.

LED connector hook design:

Equipped with specially designed LED connector hooks, it greatly facilitates the connection operation with LED fixtures. The hook design enables the cable to be connected to the LED strip or module quickly and securely without the need for complicated tools and tedious operation steps, saving installation time and labour costs, even non-professionals can easily complete the connection process, improving work efficiency.

At the same time, this hook connection also has good anti-vibration performance, which can effectively reduce the connection loosening caused by vibration or shaking, to ensure the stability and reliability of the LED lighting system in a variety of operating environments, to provide you with a long-lasting and stable lighting effect.

3. Product use scene

Home Lighting Decoration:

In home decoration, it can be used to connect all kinds of LED light strips, such as ceiling light strips in the living room, bedside light strips in the bedroom, cabinet light strips in the kitchen and so on, to create a warm, comfortable and personalised lighting atmosphere. Its flexible PVC material and flat ribbon design make the cable can be easily hidden in small gaps without affecting the overall decoration, and at the same time to meet the requirements of safety and stability of the home lighting system.

Commercial display lighting:

In the lighting design of shopping malls, shops, exhibition halls and other commercial places, it is widely used in the connection of display cabinets, windows, billboards and other lighting facilities. Its ability to carry a large current ensures a stable power supply for a large number of LED lamps and lanterns, providing sufficient and even light for the display of commodities, attracting customers' attention and enhancing the display effect and commercial value of commodities.

Electronic equipment manufacturing and maintenance:

In the production process of electronic equipment, such as computer motherboards, LCD screens, game consoles and other internal circuit connections, its accurate AWG specifications and reliable electrical performance, to meet the strict requirements of electronic equipment for signal transmission and power supply, to ensure the normal operation and stable performance of the equipment.

The cable is also ideal for repairing and upgrading electronic equipment. Its easy installation and removal makes it easy for maintenance personnel to quickly replace damaged cables or extend lines, reducing maintenance costs and time and improving the efficiency and availability of equipment maintenance.

4. Product use instructions

Pre-installation Preparation:

Carefully check the appearance of the cable for any defects such as breakage, scratches, flattening, etc. If there are any problems, you should contact the supplier for replacement. At the same time, confirm whether the purchased cable specification (18/20/22AWG) meets the actual usage requirements.

According to the installation scenario and the connected equipment, prepare the appropriate tools, such as scissors, wire strippers, screwdrivers and so on. Ensure the sharpness and accuracy of the tools to avoid unnecessary damage to the cables during operation.

Wiring and connection:

In the wiring process, the cable should be reasonably planned according to the actual installation path and space, avoiding excessive bending, twisting or stretching of the cable. For the parts that need to be bent, try to keep the bending radius not less than [X] times the thickness of the cable (specific multiples can refer to the product specification), in order to prevent the internal structure of the cable from being damaged, affecting the electrical performance.

When connecting LED fixtures, first insert one end of the cable into the LED connector hook, make sure it is inserted in place and a ‘click’ sound is heard to indicate a solid connection. Then, depending on how and where the luminaire is to be installed, fix the cable along the intended path. Fixing materials such as cable ties, cable ducts or adhesive tapes can be used to ensure that the cable is neat and stable and will not be loosened or displaced by external forces.

If splicing or extension of cables is required, use suitable terminals or soldering tools to ensure good conductivity and insulation at the connection points. After the splicing is completed, carefully insulate the connection parts, which can be wrapped with insulating tape or heat-shrinkable tubing to prevent leakage and short-circuit accidents.

Precautions for use:

The rated voltage and current of this cable should be used in strict accordance with the parameters on the product specification, and should not exceed the maximum value stipulated therein, so as not to cause electrical safety accidents. When connecting multiple LED fixtures, pay attention to calculating the total power and current to ensure that the cable can withstand the load.

Avoid exposing the cables to harsh environmental conditions such as high temperature, humidity, corrosive chemicals, etc. If the cables need to be used in special environments, such as outdoor or humid environments, appropriate protective measures should be taken, such as the use of waterproof, sunscreen, corrosion-resistant trunking or casing to protect the cables, in order to prolong the service life of the cables and to ensure that the performance of the cable is stable.

Regularly check the connection parts and overall appearance of the cable to see if there is any looseness, oxidation, breakage and so on. If problems are found, they should be repaired or replaced in time to ensure the normal operation and electrical safety of the cables.