⚡ Product Core Introduction – Manual Motor Circuit Breaker

HomeDIYer introduces the GV2ME10C - 08C Manual Motor Circuit Breaker with a current range of 0.1A - 32A. Part of the GV2ME series, this breaker is designed for motor circuit protection. It prevents damage from overloads, short circuits, and phase loss—ensuring safe and efficient operation in industrial machinery, HVAC systems, and other motor-driven equipment. This breaker is a key component in ensuring the stable operation of motors.

🔑 Main Characteristics of the Manual Motor Circuit Breaker

🎯 Precise Current Protection Range

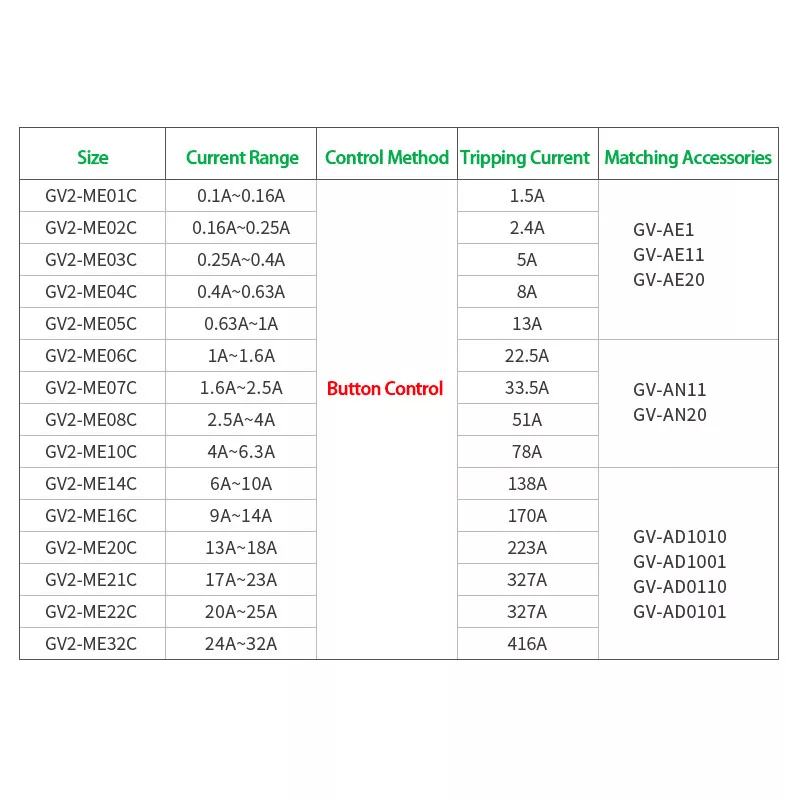

Adjustable current range from 0.1A to 32A, suitable for a wide variety of motors. Works with both small household motors (fans, washing machines) and large industrial motors (machine tools, pumps, compressors). It ensures a stable power supply during normal operation and provides fast disconnection if the current rises abnormally—effectively preventing burnout and extending motor life.

🛡️ Comprehensive Motor Protection Function

The breaker offers overload, short-circuit, and phase-loss protection. - During overload, it trips based on preset curves to avoid prolonged overheating. - In short-circuits, it trips instantly to stop high fault current. - For phase loss, it quickly detects and cuts off power, protecting the motor from damage. This reduces motor failures, downtime, and maintenance costs.

✋ Reliable Manual Operation Design

Features an easy-to-use manual operation mechanism. The handle clearly shows the breaker’s status (ON, OFF, or fault tripped), allowing operators to check at a glance. Manual operation is especially practical where direct motor start/stop control is needed. It increases reliability, flexibility, and ensures safety in emergencies.

💪 Durable Quality and Structure

Built with high-strength, flame-retardant materials resistant to heat, humidity, dust, and mechanical shock. Internal contacts use high-quality conductive, wear-resistant materials for sensitive and reliable performance—even under frequent switching. This extends service life and ensures long-term stability in motor protection.

🏭 Application Scenarios of GV2ME10C - 08C Manual Motor Circuit Breaker

🏗️ Industrial Manufacturing

Used in production lines of factories such as machining, automotive, and chemical industries. Provides reliable protection for motors driving machine tools, conveyor belts, fans, pumps, etc. Quickly disconnects faulty motors to protect the production line, ensuring efficiency and reducing losses.

🏢 Commercial and Civil Facilities

Ideal for HVAC systems in malls, hotels, and offices. Protects lift motors, fire pumps, and water pump motors in residential and commercial buildings. Ensures safe long-term operation, reduces maintenance, and improves facility reliability.

🌾 Agriculture and Breeding Industry

Suitable for irrigation pump motors, farm ventilation systems, and feed processing equipment. Withstands harsh environments like voltage fluctuations, dust, and humidity. Provides dependable protection, ensures smooth farming operations, and improves economic efficiency.

🛠️ Installation and Use Instructions

📋 Preparation Before Installation

- Check for defects (breakage, deformation, oxidation, cracks). Replace if damaged.

- Select the correct current setting (0.1A–32A) based on the motor rating.

- Use proper tools (screwdrivers, wrenches, strippers) to avoid damage.

⚙️ Installation and Connection

- Mount the breaker on the control box rail securely.

- Connect power to the input terminal (LINE) and motor wires to the output terminal (LOAD).

- Tighten all terminal screws to prevent poor connections and overheating.

🔎 Debugging and Testing

- Start the motor and check for smooth operation without abnormal noise or smoke.

- Use a clamp-on ammeter to confirm the motor current is within range.

- Simulate overload and short-circuit (with professional supervision) to test protection functions.

- Test phase-loss protection by disconnecting one phase and confirming trip response.

⚠️ Precautions for Use

- Regularly check the breaker for heat, smoke, discoloration, or odor.

- Inspect contacts—replace if worn or ablated.

- Perform comprehensive inspections every 6–12 months, depending on conditions.

📊 Specifications – Manual Motor Circuit Breaker

| Parameter |

Details |

| Model |

GV2ME10C - 08C |

| Current Range |

0.1A – 32A Adjustable |

| Protection Functions |

Overload, Short-Circuit, Phase Loss |

| Operation |

Manual, with Clear ON/OFF/Fault Indicator |

| Material |

High-Strength Flame-Retardant Housing |

| Application |

Industrial, Commercial, Civil, Agricultural Motors |

❓ FAQ – Manual Motor Circuit Breaker

Q1: Can this breaker replace a traditional MCCB?

A: No, this breaker is specifically designed for motor protection, not general distribution like MCCBs.

Q2: How often should it be maintained?

A: We recommend a check every 6–12 months, depending on usage and environment.

Q3: Does it protect against all three motor risks?

A: Yes, it covers overload, short-circuit, and phase-loss protection.