I was surprised these performed so well on my granite counter top considering the price! I thought I would go through all 5 bits but I successfully drilled through using only one bit. And it was sharp from start to finish!

I used plenty of water to lubricate, and took a few breaks to let the bit cool down.

The bit is having a hard time punching the hole

in my stainless steel kitchen sink. Gets real hot, real quick. I have to stop and let It cool. Taking forever.

The quality on these post screws seems to be really well. The size is perfect for small projects like leather and kydex. They look great. They seem to hold up very well. I have no issues with their performance. I've ordered several packs and I will continue to order.

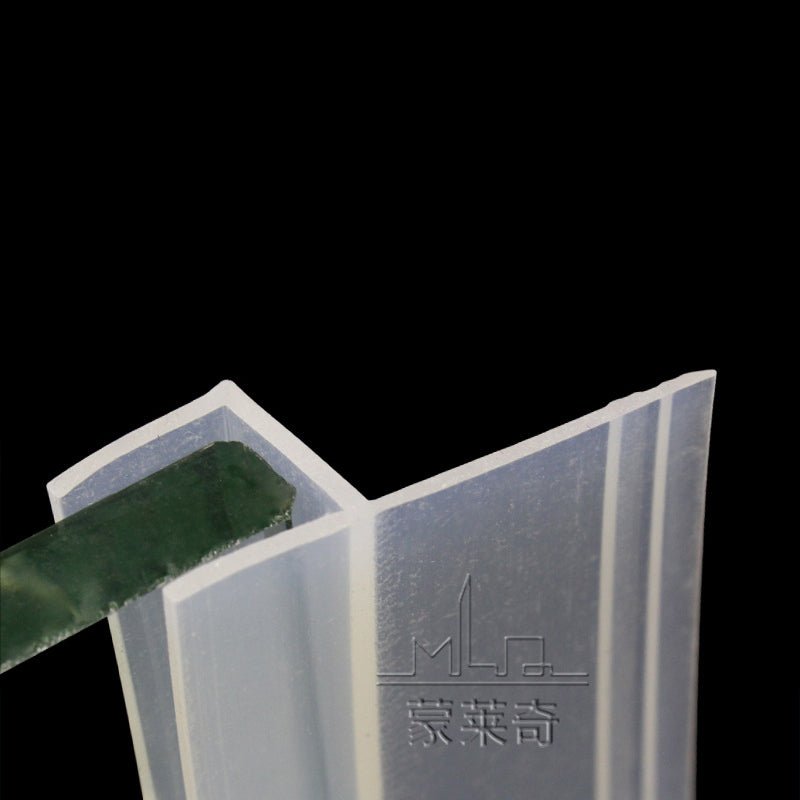

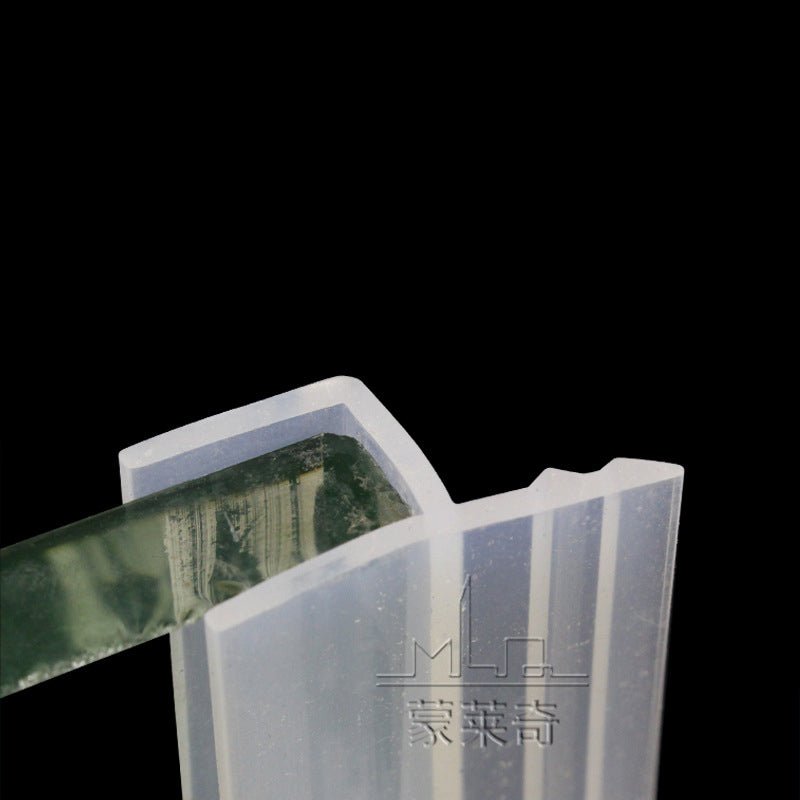

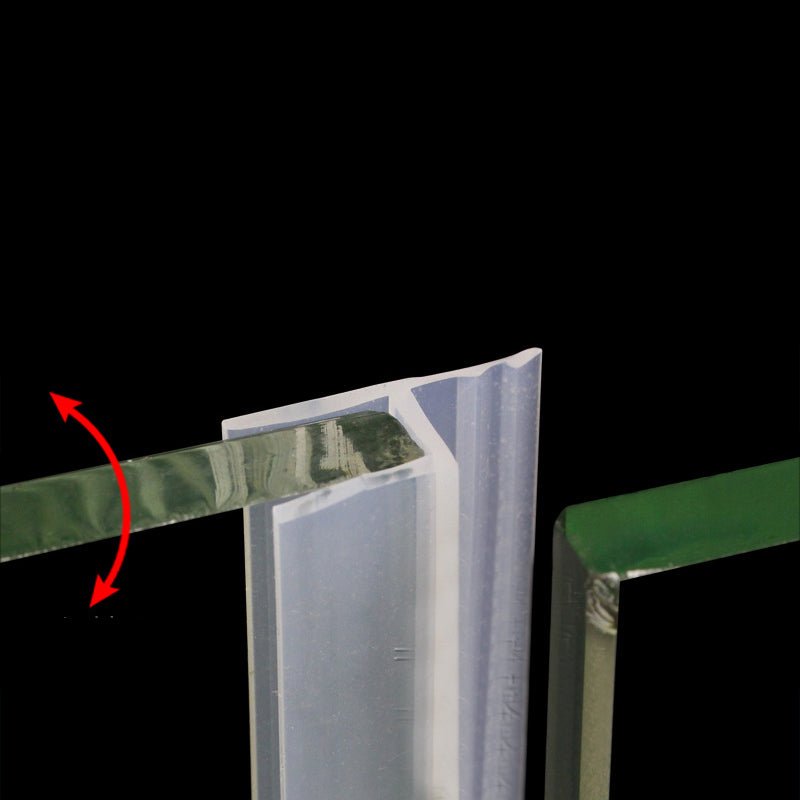

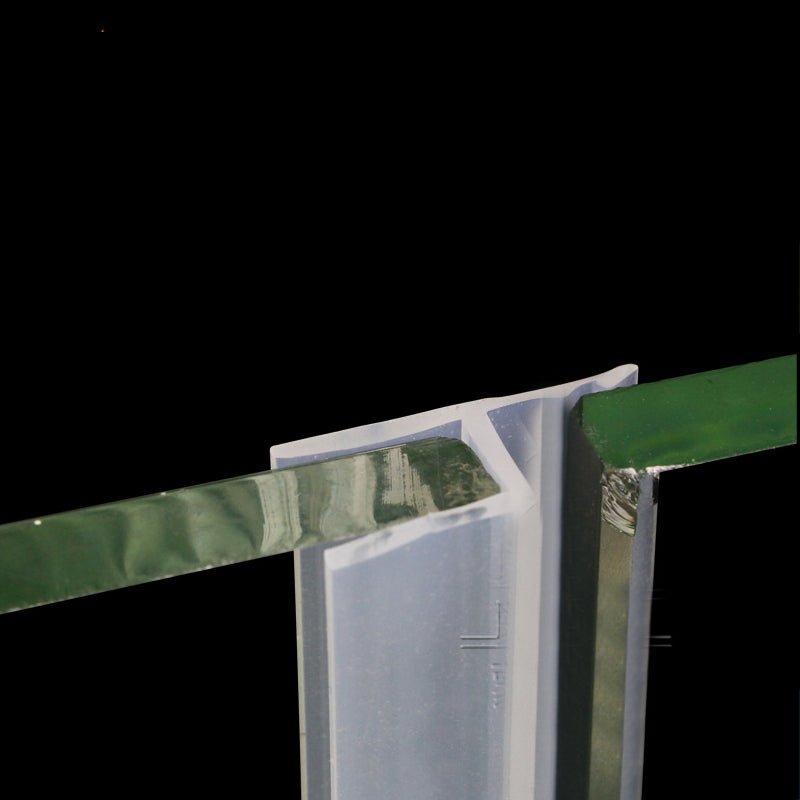

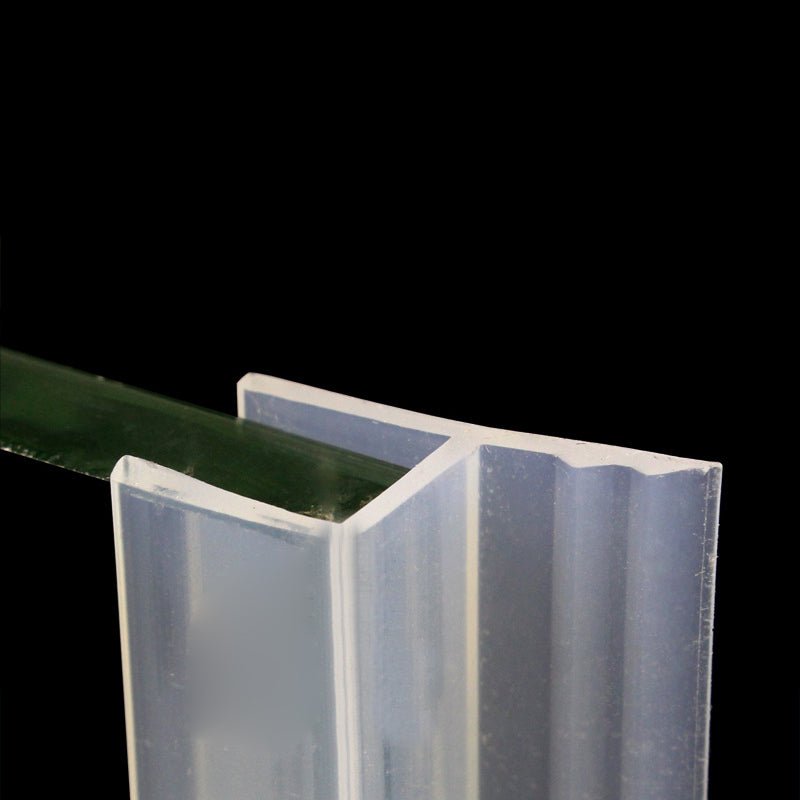

Very surprised by how simple and effective this is.

Easy to separate halves that you squeeze around the bolt.

Has a keychain, not really something I want to carry around.

Tested for various bolts and it works fine. Like it - I recommend it.