1. Product core introduction

The HomeDIYer KBPC3510 is a 35A 1000V bridge rectifier diode belonging to the MGR Rectifier Bridge KPPC series. The KBPC3510 is a 35A 1000V bridge rectifier diode belonging to the MGR Rectifier Bridge KPPC series, which is mainly used for efficiently converting AC power to DC power, and is suitable for a wide range of power supply applications due to its high current rating and voltage rating, providing reliable and stable rectification for all kinds of electrical equipment.

2. The main characteristics of the product

High current carrying capacity: Rated current is up to 35A, which can meet the rectification requirements of larger power equipment, suitable for industrial areas such as welding machines, motor drives, high-power power supplies and other equipment that need to handle large currents, to ensure stable operation under high loads, effectively avoiding damage to components due to overloading of the current, to provide reliable current conversion for the normal operation of the equipment to ensure that the overall power system to enhance the processing capacity and stability of the system. Improve the overall power processing capability and stability of the system.

High voltage withstand performance: 1000V voltage withstand level, can withstand high voltage peaks, can be used in voltage fluctuations or high-voltage environment of the electrical system, such as industrial power grid power conversion equipment, high-voltage DC transmission system rectifier link, etc., to ensure safe and reliable work under high voltage conditions, to prevent damage due to voltage breakdown, enhance the adaptability and reliability of the product in complex voltage environment, broaden its scope of application. It enhances the adaptability and reliability of the product in the complex voltage environment and widens its application scope.

High-efficiency rectification characteristics: the use of advanced semiconductor manufacturing process and optimised circuit design, with excellent rectification efficiency, can be efficiently converted from AC to DC, reduce energy loss, improve power utilisation, in the energy consumption is increasingly concerned about today, help to reduce the operating costs of the equipment and energy consumption, to contribute to energy saving and environmental protection, and at the same time for the power supply efficiency of the equipment requires a higher quality solution. Stable and reliable quality

Stable and Reliable Quality: Strict quality testing and production process control ensure stable and reliable performance. The internal diode chip and package structure have good heat dissipation performance and mechanical strength, which can maintain stable electrical performance under long-time continuous operation and different environmental conditions, reduce performance fluctuations and failure chances due to component aging and temperature changes, etc., provide a solid foundation for long-term stable power conversion, and reduce the maintenance cost and downtime of the equipment.

3. Product use scene

Industrial power supply system: In industrial production, it is widely used in all kinds of power supply equipment, such as switching power supply, linear power supply, industrial charger, etc., to provide stable DC power supply for industrial equipment. For example, in the automated production line of a factory, it provides the required DC power supply for control systems, motor drives, sensors and other equipment to ensure the normal operation of the production line; in the power supply of industrial robots, it meets the demand for high-power and high-precision power supply to ensure the stable work and precise operation of robots, and improve the efficiency and quality of industrial production.

New energy power generation field: used in solar photovoltaic power generation system and wind power generation system, the inverter converts unstable DC power into stable AC power and feeds into the power grid. The DC power generated by solar panels needs to be rectified and inverted before it can be connected to the power grid for users' use. KBPC3510 rectifier bridge can efficiently complete the work of rectification link to ensure the stable conversion and transmission of power, improve the power generation efficiency and reliability of new energy power generation system, promote the effective use of clean energy, and facilitate the development of sustainable energy.

Maintenance and transformation of electrical equipment: When repairing or upgrading old electrical equipment, it is ideal as a replacement for the original rectifier components. The rectifier components in many traditional equipment may not be able to meet the current working requirements due to old age, outdated technology or performance degradation. KBPC3510's high-current, high-voltage capability and reliable performance can enhance the power conversion efficiency and stability of the equipment, prolong the service life of the equipment, reduce the cost of equipment renewal, save money and resources for the enterprise, and at the same time, improve the performance and competitiveness of the equipment.

4. Product use instructions

Preparation before installation:

Check the appearance of the rectifier bridge for defects such as breakage, deformation, oxidation or bending of the pins, if there are any problems, contact the supplier for replacement to ensure that the quality of the KBPC3510 rectifier bridge used is intact and undamaged.

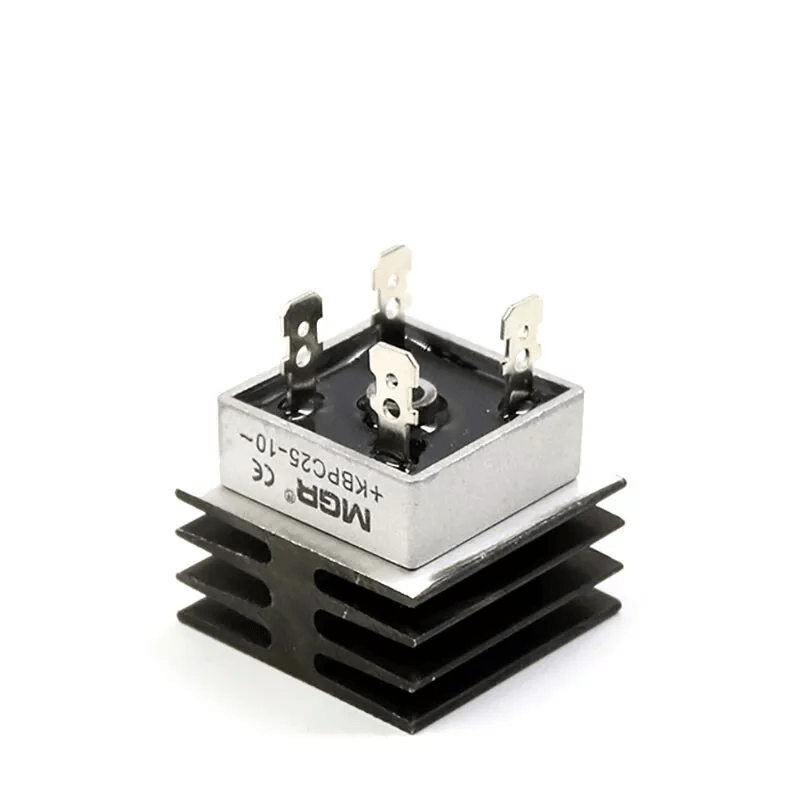

According to the circuit design and application requirements, prepare suitable heat sinks (such as heat sinks), because in high current operation will generate a certain amount of heat, good heat dissipation conditions to help ensure the normal operating temperature and performance stability of the rectifier bridge. At the same time, prepare the appropriate installation tools, such as screwdrivers, wrenches, pliers, welding equipment (if applicable), etc., to ensure the accuracy and applicability of the tools, so as to avoid damage to the rectifier bridge during the installation process.

Installation and Connection:

Mount the KBPC3510 rectifier bridge on the heat sink, ensuring close contact for heat dissipation. Use screws to secure the rectifier bridge to the heat sink, taking care to tighten them moderately to avoid damaging the component housing.

Connect the AC input and DC output correctly according to the pin markings of the rectifier bridge and the circuit schematic. Usually, the pins marked with ‘~’ or ‘AC’ are AC inputs, connected to the AC power supply; the pins marked with ‘+’ and ‘-’ are DC outputs. The pins marked with ‘+’ and ‘-’ are DC output terminals, connecting to the load or subsequent circuit components. Pay attention to the correctness and firmness of the wiring to avoid problems such as wrong wires, false connections or short circuits. After the wiring is completed, check whether all the connections are reliable, ensure that the wires are not damaged and well insulated, and prevent the occurrence of faults caused by poor electrical connections.

Debugging and testing:

After completing the installation and wiring, conduct a preliminary power-on test of the circuit. Use a multimeter and other electrical test instruments to measure the voltage at the DC output, check whether there is a normal DC voltage output, and whether the voltage value is as expected. At the same time, observe whether the rectifier bridge has abnormal heat, smoke, odour and other phenomena during the working process, if there is any problem, immediately disconnect the power, and check whether there is any failure in the wiring, heat dissipation device and the rectifier bridge itself, and make adjustments and repairs accordingly.

Precautions for use:

Regularly check and maintain the rectifier bridge to see if there is any abnormality in its appearance, such as heat, discolouration, deformation of the shell and so on. At the same time, check whether the heat sink is working properly, make sure that the contact between the heat sink and the rectifier bridge is good, and that there is no accumulation of dust and debris to affect the heat dissipation effect. If it is found that the heat dissipation is poor or the rectifier bridge shows signs of overheating, the heat sink should be cleaned up in time or other heat dissipation measures should be taken, such as increasing fan cooling, etc., in order to ensure that the rectifier bridge operates within the normal operating temperature range and prolong its service life.

During operation, the rectifier bridge should be avoided to be subjected to voltage, current and temperature shocks that exceed its rated parameters. For example, do not connect an AC power supply with too high a voltage or a load that exceeds the rated current to avoid damaging the internal diode components. At the same time, care should be taken to prevent the rectifier bridge from working continuously for a long time in a high-temperature environment. If the ambient temperature is too high, additional cooling measures should be considered to ensure that its operating performance and reliability are not affected.

When the rectifier bridge is used in a system with high requirements for electromagnetic compatibility, attention should be paid to the adoption of appropriate electromagnetic interference suppression measures, such as connecting suitable filter capacitors, inductors and other components at the AC input and DC output, in order to reduce the electromagnetic interference generated during the rectification process on the other electronic equipment and control system, and to ensure that the electromagnetic compatibility of the entire system complies with the relevant standards and requirements, and operates stably and reliably.