1. Product core introduction

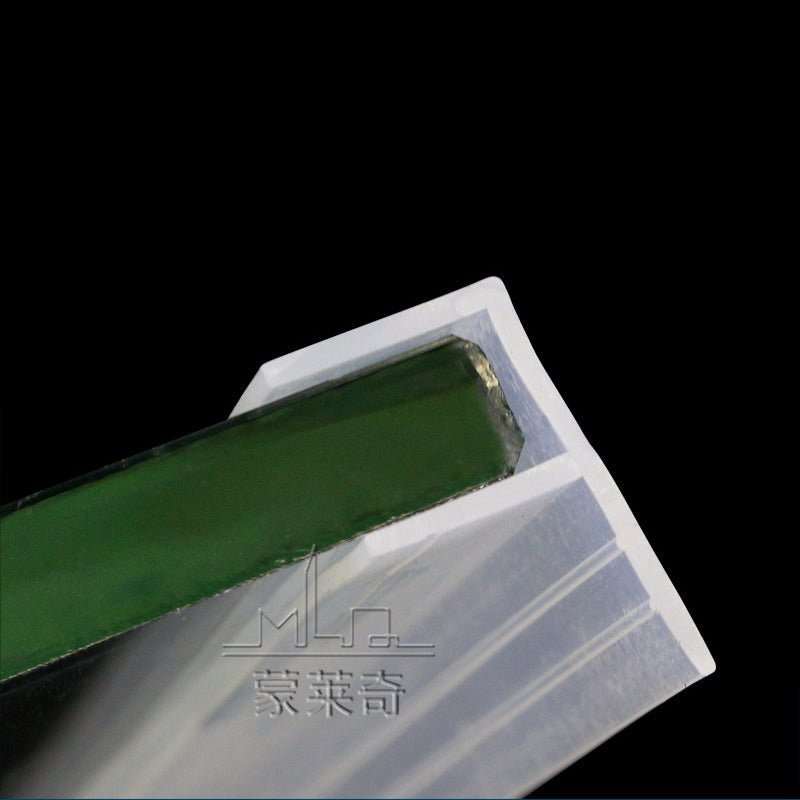

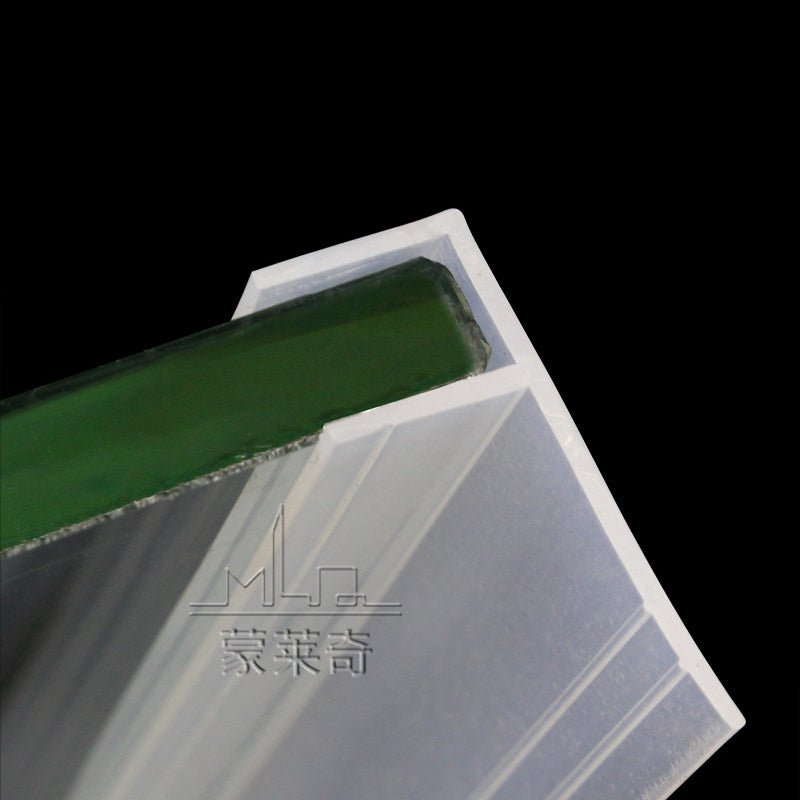

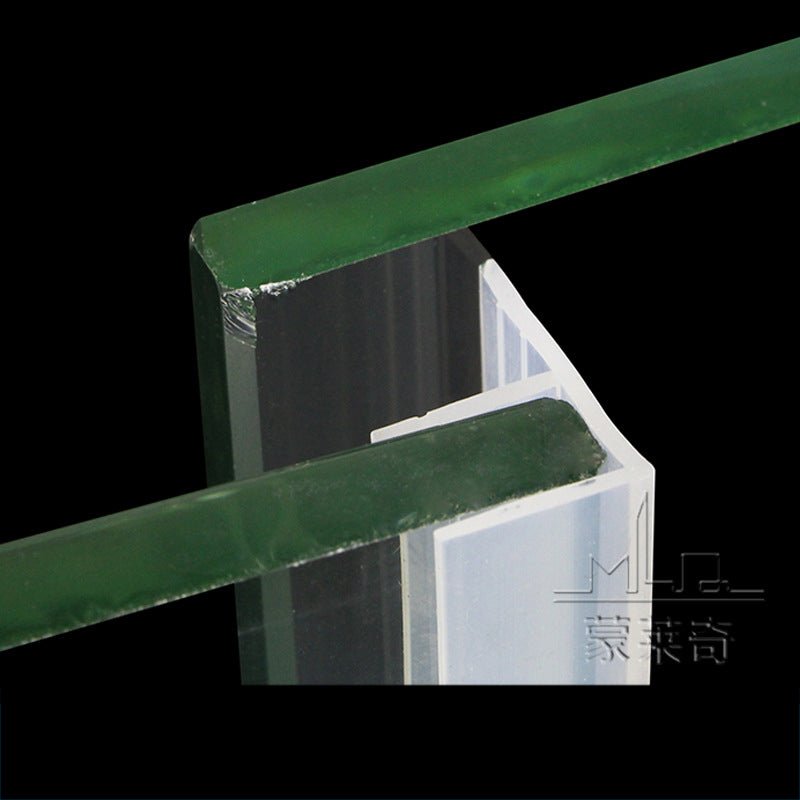

HomeDIYer presents a silicone rubber product designed for frameless glass applications. As a premium sealing material, it provides a reliable and long-lasting solution for frameless glass installations. Its excellent adhesion, flexibility and weatherability ensure a tight and long-lasting seal. Whether it's a glass shower enclosure, balcony railing or other frameless glass project, you can rely on this silicone rubber to meet your sealing needs and enhance the overall aesthetics and functionality of your space.

2. The main characteristics of the product

Outstanding adhesion performance: It has strong adhesion to glass, metal, plastic and other common materials, and can form a solid bond at the joints of frameless glass, glass and frame, effectively preventing gaps, shedding or leakage at the sealing place, ensuring the reliability and stability of the seal, and maintaining a close adhesion even under the influence of external forces, temperature changes and humidity over a long period of time. Even under the influence of long-term external forces, temperature changes and humidity, it can maintain a close adhesion state, providing a solid sealing guarantee for the frameless glass structure.

Excellent Flexibility: It has good flexibility and elasticity, and is able to expand and contract with the thermal expansion and contraction of the glass as well as undergo moderate deformation when it is impacted by external forces without rupture, breakage or loss of sealing effect. This flexibility makes it in a variety of complex use of the environment and working conditions can always maintain a tight package and sealing of the glass, effectively buffer the external stress on the sealing part of the impact of the seal to extend the service life of the seal to reduce the risk of sealing failure due to the rigidity of the material, for the safe use of the frameless glass to protect the safety of the use of the glass.

Excellent weather resistance: it can withstand the long-term erosion of various harsh natural environmental factors such as ultraviolet rays, high temperature, low temperature, humidity, oxidation, etc., and is not easy to aging, cracking, discolouration or deterioration. Whether in the strong sunshine outdoor balcony, high temperature and humid bathroom environment, or cold and dry winter climate conditions, can maintain stable physical and chemical properties, to ensure that the sealing performance is durable and reliable, to reduce the need for frequent maintenance and replacement due to environmental factors, for the long term use of frameless glass to provide a reliable guarantee to reduce the cost of use and maintenance difficulties.

Good chemical stability: It has strong resistance to common chemicals such as acids, alkalis, salts, detergents, disinfectants, etc., and will not have chemical reactions with these substances leading to performance degradation or sealing failure. This makes it able to resist the erosion of various chemical substances it may come into contact with during use, maintaining the integrity and effectiveness of the seal, and is suitable for a variety of different application scenarios, such as laboratory glass equipment sealing, glass partition sealing of industrial plants, etc., to meet the requirements of different industries for the chemical stability of sealing materials.

3. Product use scene

Commercial glass partition: In commercial office space, hotel lobby, shopping malls and other places, frameless glass partition is widely used to divide the space and create a transparent and open visual effect.H-type seals are used in the splicing and edge fixing parts of the glass partition, which can ensure the airtightness and watertightness of the partition, improve the sound insulation and privacy of the indoor space, and add a modern and fashionable atmosphere to the commercial environment to meet the requirements of commercial premises.

4. Product use instructions

Preparation:

Ensure that the frameless glass surface to be sealed is clean, dry and free of oil, dust and impurities. You can use detergent and clean rags to clean the glass surface thoroughly, and then dry it with a clean towel or dry it naturally to ensure that the silicone rubber can fully contact with the glass surface and form a good adhesion effect.

According to the size and shape of the sealing area, prepare the appropriate tools, such as glue gun, scraper, scissors, etc., and check the integrity and cleanliness of the tools to ensure that the tools can be used properly and will not adversely affect the quality of the silicone rubber and the sealing effect.

Choose the appropriate specifications and models of HomeDIYer silicone rubber products, according to the product manual to understand its scope of application, curing time, operating temperature and other parameters, to ensure that the product meets the specific requirements of the frameless glass sealing project.

Construction Steps:

Install the silicone rubber hose on the glue gun, follow the instructions in the product manual to correctly adjust the glue speed and pressure of the glue gun to ensure even and smooth glue dispensing.

In the sealing parts of frameless glass, such as joints, edges, etc., slowly and continuously extrude silicone rubber along the seams to ensure that the silicone rubber is filled with full and even, to avoid defects such as broken glue, bubbles or voids. For vertical or inclined sealing parts, you can use from top to bottom or from one side to the other side of the sequence of glue, to ensure that the silicone rubber under the action of gravity can fully fill the gap and form a good sealing shape.

Using a spatula or other suitable tools, trim the surface of the extruded silicone rubber smooth and flat, so that it closely fits the glass surface, and remove the excess silicone rubber. In the process of trimming, pay attention to the operation of moderate strength, to avoid excessive extrusion lead to silicone rubber and glass surface adhesion decreased or sealing performance is impaired, and at the same time to ensure that the appearance of the sealing parts of the neat, beautiful.

According to the requirements of the curing time of silicone rubber products, after the construction is completed, avoid touching, moving or force on the sealing part, to ensure that the silicone rubber can be fully cured in a stable environment to achieve the best sealing performance. In general, the initial curing time of silicone rubber ranges from a few hours to a day, and full curing may take several days, depending on the product formulation, ambient temperature, humidity and other factors.

Precautions for use:

During the curing process of silicone rubber, keep the construction site well ventilated, but avoid strong wind blowing directly on the sealing part, so as not to affect the curing quality and shape of silicone rubber. At the same time, care should be taken to avoid silicone rubber coming into contact with water, oil, solvents and other substances to prevent its surface from being contaminated or sealing performance affected.

Silicone rubber should be cleaned up in time after use of the residual silicone rubber on the glue gun and other tools, so as not to affect the next use of the tool after curing. Special cleaning agents or solvents can be used to clean the tools, but care should be taken to choose cleaning agents that do not chemically react with silicone rubber and follow safe operating procedures to avoid contact with skin and eyes.