1. Product core introduction

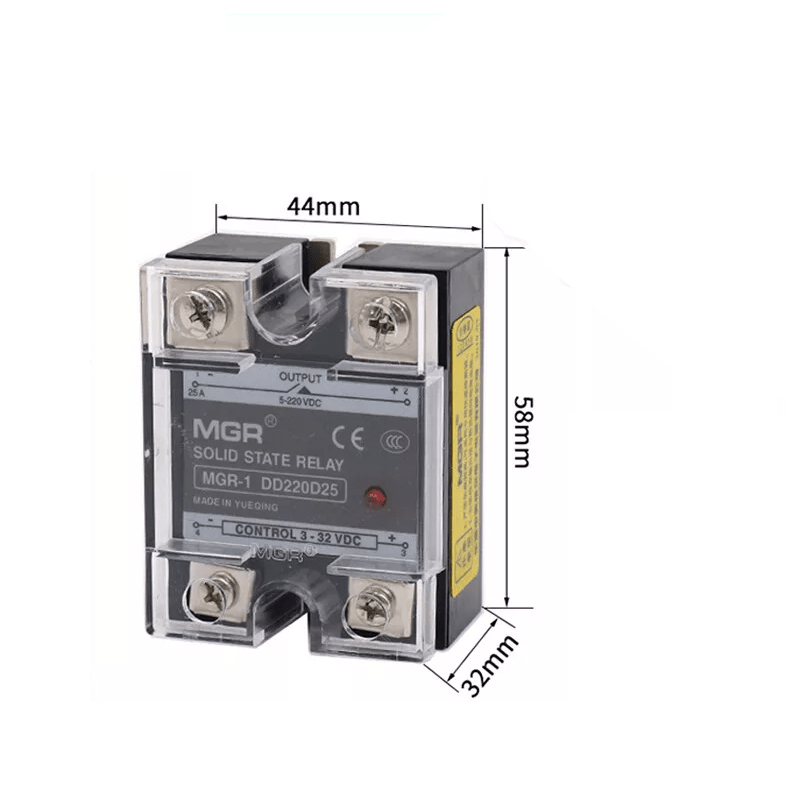

HomeDIYer presents this solid state relay module SSR with a current range of 10 - 150 amps for DC - DC, DC - AC single-phase application scenarios and a control voltage of 3 - 32V DC As an MGR single-phase solid state relay, it provides reliable and efficient switching for a wide range of electrical systems and can handle different power levels and voltage conversion requirements, whether it is for industrial, automotive or power electronics applications to achieve precise and stable control. The MGR single-phase solid state relays provide reliable and efficient switching for a wide range of electrical systems, handling different power levels and voltage conversion requirements for precise and stable control in industrial, automotive and power electronics applications.

2. The main characteristics of the product

Wide Current Adaptation Range: With a wide current carrying capacity of 10 - 150 amps, it can meet a wide range of equipment needs from low power to high power. Whether it is low-current circuits in small electronic equipment or high-current loads in industrial-grade large-scale equipment, it can find the right current specification to ensure stable and reliable operation under various power demands, avoid equipment failures due to insufficient or excessive current capacity, and provide precisely adapted current-switching solutions for different electrical systems to enhance the compatibility and reliability of the system.

Multi-functional voltage conversion: It supports DC-DC and DC-AC single-phase conversion, which can adapt to complex and variable voltage requirements. In practical applications, it can convert DC to AC for AC loads, or convert between different DC voltage levels to meet the voltage requirements of specific equipment, expanding the scope of application of the relay, enabling it to play a role in more diverse electrical environments, providing users with convenient and flexible voltage conversion and control functions, and optimising the design and operational efficiency of the entire electrical system.

Wide Control Voltage Range: The 3 - 32V DC control voltage range makes it compatible with many common control signal sources. Both low-voltage microcontroller outputs and converted medium-voltage control signals can effectively drive the relay to work, facilitating users to seamlessly integrate the relay according to the voltage conditions of the existing control system without the need for additional complex voltage conversion circuits, which reduces the complexity and cost of the system design, and enhances the applicability and ease of use of the relay on different control platforms.

Fast and precise switching: Advanced solid-state technology is used to achieve fast and precise switching action. Compared with traditional relays, its response time is significantly shorter, and it can complete the on and off of the circuit in an instant, ensuring precise control of the load, especially suitable for application scenarios that require high switching speed and control precision, such as high-frequency motor drive, precision power management, etc., to improve the working efficiency and performance of the equipment, and to satisfy the stringent requirements of the modern electrical system for high-speed and high-precision control.

High reliability and stability: The internal structure is well-designed, with high-quality semiconductor components and stable circuit layout, providing excellent anti-interference capability and stability. In a variety of complex electrical environments, it can resist voltage fluctuations, electromagnetic interference and other unfavourable factors to ensure stable and reliable working conditions, reduce the chance of malfunctions and failures due to external interference, provide a solid guarantee for long-term continuous operation of the electrical system, reduce the cost of maintenance of the equipment and downtime, and improve the production efficiency and overall reliability of the system.

3. Product use scene

Industrial automation control: In industrial production lines, it is widely used in motor control, heating system and power management of automation equipment. For motors of different powers, suitable relay specifications can be selected according to their rated currents to achieve precise start, stop and speed control; in heating equipment, precise control of heating element current flow and breakage to achieve precise adjustment of temperature to meet the strict requirements of process parameters during industrial production; at the same time, in the power supply switching and distribution of automation equipment, to ensure a stable and reliable supply of electricity to improve At the same time, in the power switching and distribution of automation equipment, it ensures stable and reliable power supply, improves production efficiency and product quality, and guarantees the stable operation of industrial automation system.

Automotive electronic system: In the automotive electrical system, it is used to control various electronic equipments in automobiles, such as lights, electric seats, window lifting motors, automotive air-conditioning compressors and so on. Its wide current range and multi-functional voltage conversion capability can adapt to the complex characteristics of the automotive power supply system, achieve efficient control of different loads, enhance the performance and reliability of the automotive electronic system, and provide a more comfortable and safe driving experience for the driver and passengers, as well as to meet the requirements of automotive electronic equipment for miniaturisation, high reliability and energy saving, which plays an important role in modern automotive electronics technology.

Power electronic equipment: In power conversion equipment, inverters, UPS (uninterruptible power supply) and other power electronic devices, as a key switching element, responsible for the realisation of the conversion and control of electric energy. It can convert DC power into AC power, supply power to AC loads, or switch and regulate between DC power sources of different voltage levels to ensure that the power electronic equipment outputs stable and reliable power to meet the requirements of various electronic equipment on power quality and voltage adaptability, which has an important position in the application of power electronics, and provides a strong support for guaranteeing the stability and reliability of power supply.

4. Product use instructions

Preparation before installation:

Check the appearance of the relay module for defects such as breakage, deformation, oxidation or bending of the pins, etc. If there are any problems, contact the supplier for replacement in time to ensure that the quality of the SSR solid state relay used is intact and undamaged.

Determine the installation position of the relay according to the actual application scenario and the requirements of the control system, and prepare suitable installation tools, such as screwdrivers, spanners, pliers, heat sinks (if required), etc. Ensure the precision and applicability of the tools to avoid damaging the relay in the installation process. At the same time, make sure that the installation environment is in line with the working conditions of the relay, avoiding high temperature, humidity, strong magnetic field and other unfavourable factors that may affect its performance.

Installation and connection:

Mount the solid state relay on a suitable heat sink (e.g. metal heat sink). If the operating current is high, good heat dissipation conditions are essential to ensure that the relay operates within the normal operating temperature range. Use screws to secure the relay to the heat sink, taking care not to over tighten as this may damage the relay case.

According to the pin definition of the relay and the electrical connection requirements of the control system, connect the control signal input terminal (corresponding to 3 - 32V DC control voltage) to the control source and the load terminal (connecting DC or AC load according to the application scenario) to the corresponding electrical equipment using wires of suitable specifications, paying attention to the correctness and firmness of the wiring, avoiding problems such as connecting the wrong wires, false connections or short-circuits. After the wiring is completed, check whether all the connections are firm and reliable, and make sure that the wires are not damaged and have good insulation to prevent malfunctions caused by poor electrical connections.