e go-to choice for projects demanding lightweight durability and resistance to rust—whether you’re building a boat, restoring a vintage car, or assembling outdoor furniture. But using the wrong type or pairing them with incompatible metals can lead to costly corrosion. At HomeDIYer, we specialize in high-performance aluminum alloy screws designed to withstand harsh environments. In this guide, we’ll cover everything from material selection to installation best practices.

1. Why Aluminum Alloy Screws?

Aluminum alloys (e.g., 6061, 7075) offer unique advantages:

- Lightweight: 1/3 the weight of steel, reducing stress on structures.

- Corrosion Resistance: Naturally resistant to rust, ideal for marine or humid environments.

- Thermal Conductivity: Dissipates heat efficiently, perfect for engines or electronics.

Key Use Cases:

- Marine: Propeller mounts, deck hardware.

- Automotive: Engine components, custom bike frames.

- DIY: Outdoor furniture, solar panel mounts.

2. Types of Aluminum Alloy Screws

a. Zinc-Aluminum Coated Screws

- Enhanced corrosion resistance for saltwater applications.

- Example: Zinc-aluminum-coated alloy steel socket head screw.

b. Hex Socket Head Screws

- Precision tightening with hex keys (e.g., M3x8mm countersunk hex socket screw).

- Ideal for tight spaces in machinery or electronics.

c. Stainless Steel & Aluminum Combos

- Use stainless steel screws with aluminum alloys cautiously—add insulating washers to prevent galvanic corrosion.

3. Avoiding Galvanic Corrosion

When aluminum contacts dissimilar metals (e.g., steel), electrolysis can cause rapid rust. Fixes include:

- Insulation: Use nylon or rubber washers between aluminum and steel.

- Coatings: Apply anti-seize lubricant or anodize aluminum parts.

- Material Match: Pair aluminum with compatible metals like titanium or stainless steel (grade 316).

Warning: Avoid black-oxide alloy steel screws into aluminum without insulation—this combo accelerates corrosion.

4. Choosing the Right Screw Size

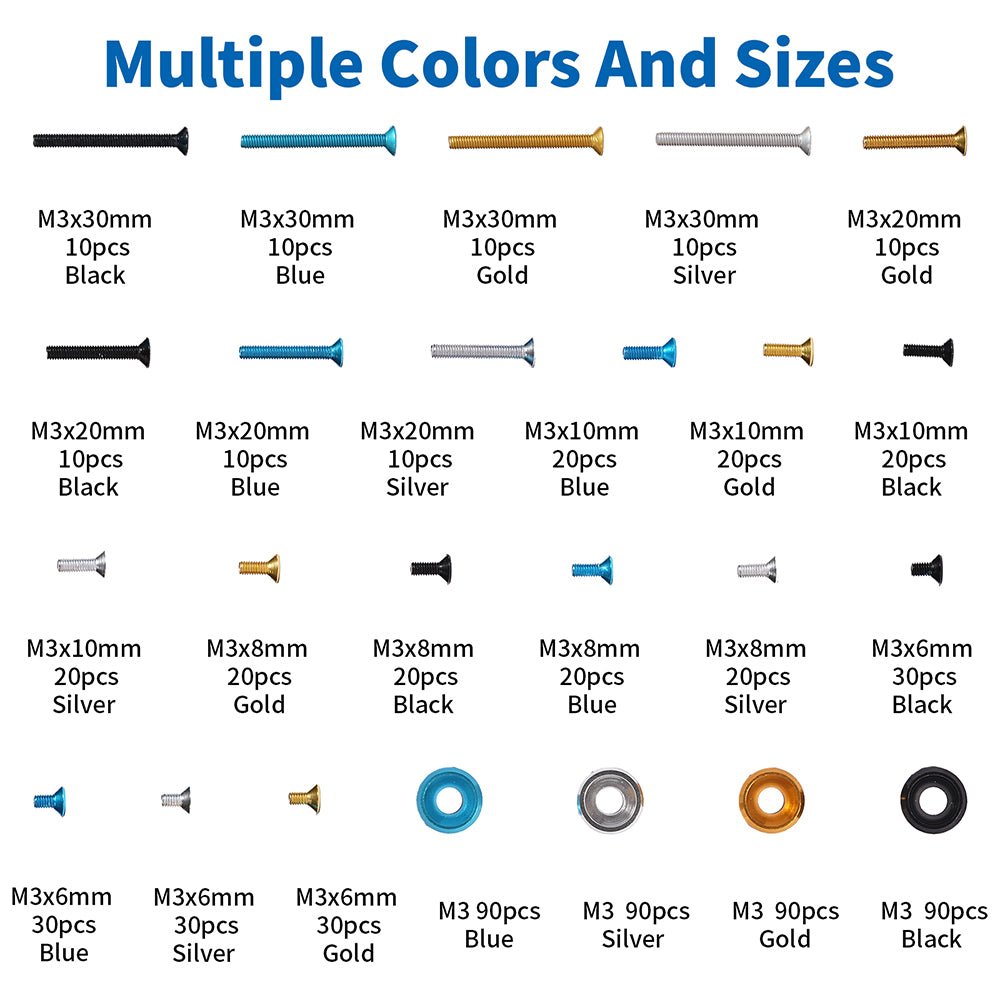

- M3 Screws: For lightweight assemblies (e.g., electronics, small brackets).

- M4 Screws: Handle medium loads (e.g., automotive panels, marine railings).

- Length Rule: Ensure threads engage at least 1.5x the screw diameter into the material.

Pro Tip: For T-slot beams, use aluminum alloy screws for T-slot beams with integrated washers.

5. Installation Best Practices

a. Pre-Drilling

- Always drill pilot holes slightly smaller than the screw diameter to prevent stripping.

- Use cutting fluid for hard alloys like 7075.

b. Torque Control

- Aluminum is softer than steel—over-tightening can strip threads. Use a torque wrench set to 75% of steel screw specs.

c. Thread Locking

- Apply low-strength threadlocker (e.g., Loctite 222) for vibrations, but avoid corrosive formulas.

6. FAQs Answered

Q: Can I use steel screws with aluminum?

A: Yes, but insulate the connection with nylon washers or coatings to prevent galvanic corrosion.

Q: What’s the best screw for saltwater environments?

A: Opt for zinc-aluminum alloy screws or marine-grade stainless steel (316) with protective coatings.

Q: How do I remove a stripped aluminum screw?

A: Use a screw extractor kit or gently drill out the screw with a left-hand drill bit.

7. Why Choose HomeDIYer Aluminum Alloy Screws?

- Marine-Grade Options: Zinc-aluminum coatings for saltwater durability.

- Precision Sizing: M3 to M6 screws with hex, Phillips, or Torx drives.

- Bulk Packs: Save on 500+ units for large-scale projects.

8. Pro Tips for Longevity

- Clean Regularly: Rinse salt or debris from screws in marine setups.

- Inspect Annually: Check for early signs of corrosion around joints.

- Store Dry: Keep screws in sealed containers with silica gel packs.

By mastering the nuances of aluminum alloy screws, you’ll ensure your projects stay lightweight, rust-free, and structurally sound—whether you’re crafting a custom boat or upgrading your workshop. Explore our Aluminum Alloy Screws Collection for premium fasteners engineered to last!