1. Product core introduction

The HomeDIYer 2/3/4/5/6/8 Multi-Conductor Shielded Cable with 18/20/22 - 28AWG Tinned Copper Signal Wire is a professional and practical cable in grey. The cables are designed to provide DIY enthusiasts with reliable signal transmission solutions, whether it's for building electronic devices in the home or connecting signals in small industrial environments, and are a key guarantee of signal transmission thanks to their stable performance.

2. The main characteristics of the product

Diversified core options: 2 to 8 core configurations to meet the needs of different levels of complexity of signal transmission. From simple two-way signal transmission to multi-channel data interaction, users can choose flexibly according to the actual project, effectively avoiding idle resources or over-configuration, so that the wiring is more accurate and efficient, to adapt to a variety of personalised application scenarios.

High-quality tinned copper signal cable: The signal cable is made of tinned copper with excellent conductivity, which can minimise signal loss and ensure accurate signal transmission. At the same time, the tinned layer provides good protection against oxidation and corrosion for the copper wire, which can maintain stable electrical performance for a long time even in harsh environments, greatly enhancing the durability and reliability of the cable, and reducing the post maintenance costs.

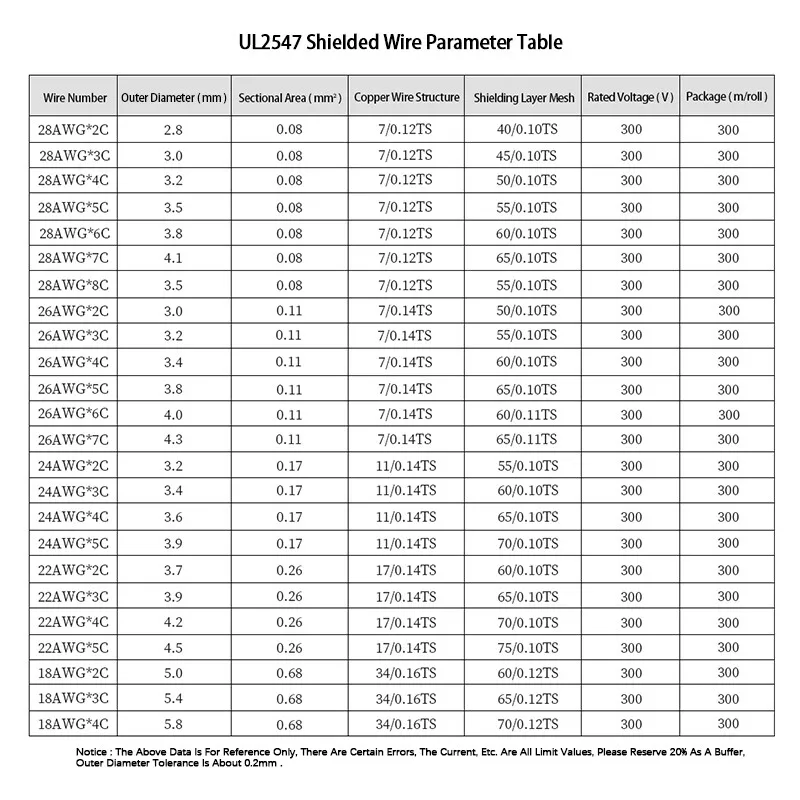

Precise AWG specification range: Covering 18/20/22 - 28AWG multiple precision specifications, each corresponding to a specific wire diameter and electrical characteristics. Users can precisely select the most suitable AWG specifications according to the specific signal transmission distance, current carrying requirements and the compatibility of the connected equipment, so as to optimise the performance of the entire electrical system, and to meet the quality of the signal transmission while achieving the rational use of resources and effective control of costs.

Excellent shielding performance: Equipped with professional shielding layer, it can effectively block external electromagnetic interference (EMI) and radio frequency interference (RFI), and build a stable and pure signal transmission channel for internal signal lines. This enables the cable to ensure reliable transmission of weak signals in areas with complex electromagnetic environments, such as factory floors, electronic equipment concentration areas, and the periphery of communication base stations, etc. It significantly reduces the probability of signal distortion, BER, etc., and strongly guarantees the accuracy and stability of data transmission and enhances the operational reliability of the entire system.

Practicality of grey appearance: the grey appearance design not only gives the cable a professional, low-key visual image, but also has excellent versatility and concealment. In all kinds of industrial, commercial and civil environments, grey cables can naturally integrate into the surrounding environment, reduce the sense of visual abruptness, facilitate unified planning and marking management in the wiring process, help to improve the construction efficiency and the overall aesthetics of the wiring, and add a delicate and professional atmosphere to the user's project.

3. Product use scene

Smart Home System Integration: In the construction of smart home, it is used to connect smart lights, smart sockets, smart curtains, smart sensors and other devices to achieve stable signal transmission and collaborative work between devices. Its shielding performance effectively avoids electromagnetic interference generated by various types of electrical equipment in the home environment, ensuring that smart devices can accurately receive and execute control commands, creating a convenient, comfortable and intelligent home life experience for users.

Electronic equipment research and development and maintenance: for electronic equipment developers, in the design and testing of electronic circuits, the cable can be used as a key component of internal signal transmission, to ensure stable signal transmission and accurate measurement, to help the smooth progress of product development. In the field of electronic equipment maintenance, its multi-core structure and easy-to-operate features facilitate maintenance personnel to quickly replace the faulty cable and restore the normal operation of the equipment, which is widely used in the maintenance scenarios of various types of electronic equipment, such as computer motherboards, mobile phones, tablet PCs, game consoles and so on.

Small industrial automation projects: in the automated production lines of small factories, such as automated packaging equipment, small CNC machining centres, intelligent warehousing and logistics equipment, etc., connecting controllers, sensors, actuators and other components to ensure accurate transmission of control signals and feedback signals, and to ensure the efficient and stable operation of the production line. Even under the electromagnetic interference in the industrial environment, it can reliably transmit signals, improve production efficiency and product quality, and provide strong support for the automation upgrading of small industrial enterprises.

Audio-video equipment installation and commissioning: in the home theatre system, professional recording studios, broadcasting stations, video monitoring systems and other audio-video equipment wiring installation, used to connect the audio and video signal lines between the speakers, amplifiers, mixing consoles, cameras, video monitors and other equipment. Its good shielding performance can effectively resist external electromagnetic interference, to ensure high-fidelity reproduction of audio signals and video signals, clear and stable transmission, to bring users high-quality audio-visual enjoyment.

4. Product use instructions

Pre-installation Preparation:

Carry out a comprehensive appearance inspection of the cable to see if there is any physical damage such as breakage, scratches, flattening, etc., and pay special attention to whether the shielding layer is intact and undamaged. If any abnormality is found, stop using it immediately and contact the supplier for replacement to ensure that the quality of the cable used is reliable.

According to the actual application scenarios and equipment connection requirements, carefully determine the number of cable cores and AWG specifications required, and prepare the corresponding connection terminals, wire stripping tools, crimping pliers, soldering irons (if soldering operations are involved) and other installation tools. Ensure the accuracy and applicability of the tools to avoid damage to the cable during installation due to improper tools, affecting its performance and service life.

Wiring and connection:

When carrying out wiring operations, the cable route should be planned in advance according to the actual installation path and environmental conditions to avoid excessive bending, twisting or stretching of the cable. For the parts that need to be bent, be sure to keep the bending radius of the cable not less than 3 times the outer diameter (specific multiples can refer to the product specification), to prevent the internal structure of the cable from being damaged, which in turn affects the signal transmission performance.

When connecting with the equipment, firstly, use the wire stripping tool to carefully strip off the insulation layer at the end of the cable to reveal the appropriate length of tinned copper signal wire (generally according to the requirements of the connection terminal, the length of the exposed length of about 5 mm), and then insert the signal wire into the connection terminal, and use the crimping pliers for firm compression, to ensure that the connection is reliable and the contact is good. If the connection is made by welding, the appropriate solder and welding process should be used to ensure that the solder joints are firm, smooth and free from false soldering. After the connection is completed, use insulating tape or heat-shrinkable tubing to carefully insulate the connection to prevent leakage and short-circuit accidents and ensure electrical safety.

Precautions for use:

Strictly follow the rated voltage and current parameters specified in the product specification to use this cable, and do not exceed their maximum values, so as not to cause electrical safety accidents, causing damage to equipment or endangering personal safety, and at the same time avoid problems such as degradation of signal transmission quality due to overloading. When connecting multiple devices, the total power and current should be accurately calculated to ensure that the cable can safely and stably carry the load.

Avoid as much as possible the cable contact with high temperature, open flame, humidity, corrosive chemicals and other harsh environmental conditions. If used in special environments, such as outdoors, high-temperature workshops, chemical sites, etc., appropriate protective measures should be taken in advance, such as the use of fireproof, waterproof, corrosion-resistant wire troughs or casings to properly protect the cable in order to extend the service life of the cable to ensure that it can still maintain a stable performance performance in harsh environments.

Regularly inspect the connection parts and overall appearance of the cables to see if there is any looseness, oxidation, breakage, etc.. If any problems are found, they should be repaired or replaced in a timely manner to ensure that the cables are always in normal working condition and guarantee the reliability of signal transmission. When carrying out equipment maintenance or overhaul, attention should also be paid to the protection of the cable to avoid unnecessary damage caused by human negligence.