1. Product core introduction

HomeDIYer 304 Stainless Steel Anchored Swivel Jaw Eye Connector from M4 to M20 This high-quality connector is made of durable 304 stainless steel and features a swivel jaw eye design for all types of applications that require chain link fasteners. It offers excellent strength, corrosion resistance and flexibility to ensure a reliable connection.

2. The main characteristics of the product

High-quality 304 stainless steel material: 304 stainless steel is selected, which has good corrosion resistance, can maintain stable performance in humid, acid and alkali and other harsh environments, not easy to rust, effectively extend the service life, suitable for outdoor facilities, marine engineering, chemical equipment and other occasions with high requirements for rust prevention, to ensure that the connection parts of the long term reliability, reduce maintenance costs and failure of the connection due to rust, and at the same time, ensure the It also ensures the safety and stability of the product in various environments.

Advantage of rotating jaws: The unique structure of rotating jaws enables the connector to rotate freely when connecting chains or other accessories, avoiding stress concentration due to twisting of chains, reducing wear and fatigue damage, and improving the service life of chains, as well as facilitating the connection and operation at different angles, which enhances the flexibility and convenience of use, and is suitable for a variety of complex working environments and applications, such as lifting equipment, ship mooring, overhead lifting, etc. equipment, ship mooring, aerial work, etc.

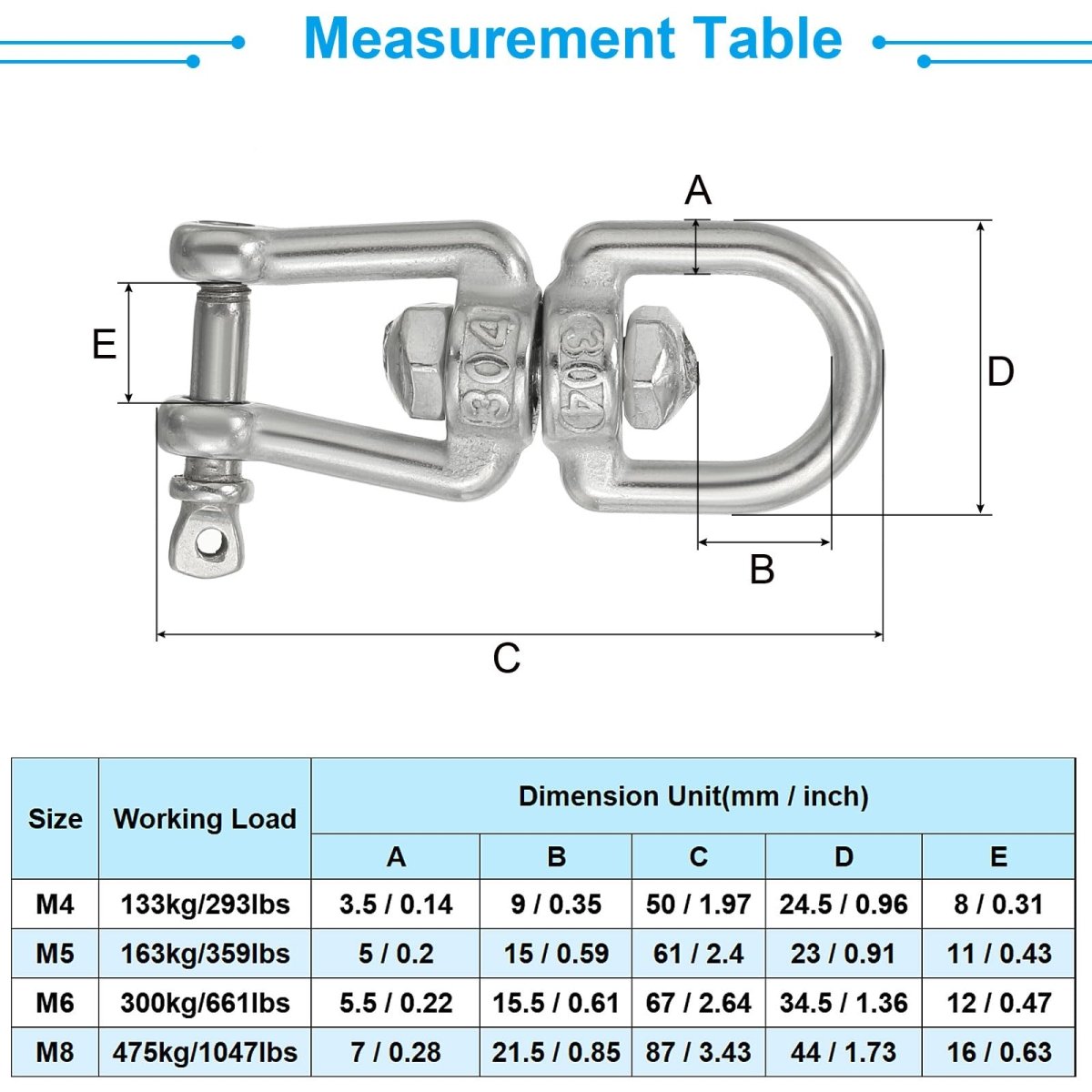

Precise size: M4 to M20 sizes are available to meet different load capacity and size requirements of the application scenarios, to ensure precise matching with various chains, ropes, rings and other components, whether it is a small DIY crafts, light lifting in home renovation, or medium-sized lifting equipment in industrial production, you can find the right specifications, so that users can easily choose according to the actual needs to improve installation efficiency and connection quality, and achieve accurate and precise connection quality. Installation efficiency and connection quality, to achieve accurate and reliable fastening effect, to protect the safe operation of equipment or projects.

High strength and reliability: After careful design and manufacture, the connector has high strength and load-bearing capacity, able to withstand large tensile and impact forces, not easy to deform or fracture under normal conditions of use, to ensure that the connection of the firmness and stability of a variety of occasions that require a reliable connection to provide a solid guarantee to reduce the risk of safety accidents arising from the failure of the connecting parts for the field of higher safety requirements, such as building construction, mining, mining, and other industries. It is suitable for areas with high safety requirements, such as construction, mining, logistics and transport.

3. Product use scene

DIY and home decoration: In home DIY projects, such as building patio swings, installing hammocks, fixing balcony drying racks, etc., it can be used for connecting chains and support structures, and its stainless steel material is beautiful and rust-resistant, and its rotating jaws are designed to facilitate adjusting the angle of the chain to ensure a solid installation and safety in use; in home decoration, it is used for lifting lamps and light items such as decorative hangings, which can satisfy the demand of home decoration for small-scale lifting operations. In home decoration, it is used for lifting light objects such as lamps and decorative hangings, which can meet the demand for small lifting operations in home decoration, provide convenience and support for the arrangement and transformation of home environment, and also enhance the safety and stability of home furnishings.

Outdoor leisure and sports equipment: widely used in outdoor leisure facilities, such as tents, awnings, camping hammocks, etc., as well as sports equipment, such as climbing ropes, fitness equipment connection and fixation, its corrosion resistance and high strength to adapt to outdoor complex climatic conditions and frequent use of scenarios, to ensure that the equipment in the use of the process of safety and reliability for outdoor enthusiasts to provide safe and comfortable leisure and sports experience, to meet people's demand for outdoor activities, to provide convenience and support for the layout and transformation of the home environment, while enhancing the safety and stability of household goods. It provides outdoor enthusiasts with a safe and comfortable leisure and sports experience and meets people's demand for outdoor activities.

Industrial and commercial applications: in industrial production, it is used for chain connection of cranes, hoists, conveyor belts and other equipments, as well as bundling and lifting of goods, which can withstand large working loads and ensure efficient and safe industrial production; in the commercial field, such as installation of shelves in shopping malls, suspension of billboards, and handling of goods in logistic warehouses, etc., it also plays an important role, with its reliable performance and diversified specifications. Its reliable performance and diversified specifications can meet the needs of different commercial scenarios, improve the efficiency and safety of commercial operations, and provide strong support for the development of enterprises.

4. Product use instructions

Preparation before installation:

Check the appearance of the connector for cracks, deformation, scratches and other defects to ensure that the product quality is intact. Also check whether the required specifications match the actual application scenarios, and replace them in time if there are any problems, so as not to affect the installation effect and use performance.

According to the material, shape and size of the connected parts, choose the appropriate installation tools, such as spanners, pliers, screwdrivers, etc., and make sure that the tools are clean, sharp and function properly, so as not to cause damage to the connector or the connected parts during the installation process.

Use a cleaning cloth or appropriate solvent to clean the surface of the connected parts, remove oil, rust, dust and other impurities, and ensure that the surface is dry, flat and smooth to ensure that the connector and the connected parts can be tightly adhered to each other to achieve a good connection and improve the stability and reliability of the connection.

Installation steps:

Pass the chain or other connecting parts through the rotating jaws of the connector, make sure that the parts are centred in the eyes and there is no twisting or winding phenomenon, and reserve a suitable length according to the actual needs for subsequent connection and fixing operations.

If you need to use with other accessories (such as nuts, bolts, rings, etc.), the corresponding accessories will be installed in the connector's threaded portion or connection parts, use the appropriate tools in accordance with the specified tightening torque or connection method for fastening, to ensure that the connection is firm and reliable, to prevent the use of the process of loosening or falling off.

After the installation is completed, check the connection part of the connector again to make sure that the connection between the chain and the connector is tight and there is no sign of loosening, and at the same time check whether the rotation of the rotating jaws is flexible and free, if there is any stagnation or unsmoothness, it should be adjusted in time or eliminate the faults to ensure that the connector can work normally in the process of using it to play its due role.

Precautions for use:

In the process of use, regularly check the connector connection parts whether there are signs of loosening, deformation, wear and tear, especially after the equipment is subjected to vibration, shock, frequent load changes or long-term use, such as found that the problem should be taken in a timely manner to take appropriate measures to repair or replace, to ensure that the connection is safe and reliable. For connectors in industrial equipment, it is recommended to carry out regular inspection and maintenance in accordance with the maintenance cycle of the equipment, such as cleaning the connection parts, lubricating the rotating jaws, checking the connector's load-bearing capacity, etc., in order to extend its service life and ensure the normal operation of the equipment.

Avoid the connector to withstand loads exceeding its rated carrying capacity. In the process of design and use, the specification and model of the connector should be reasonably selected according to the actual working conditions to ensure that it can withstand the applied tension, pressure or impact to prevent the connector from breaking or being damaged due to overloading, which may cause safety accidents. At the same time, attention should be paid to avoid the use of connectors in harsh environmental conditions (such as high temperature, low temperature, strong winds, heavy rain, etc.), so as not to affect its performance and life.

When storing and handling the connector, avoid collision, extrusion or friction with other hard objects to prevent the surface of the connector from being scratched, deformed or damaged, which will affect its appearance and performance. Store the connector in a dry, ventilated environment without corrosive gases and keep it in a proper place so that it can be kept in good condition when it is used next time.