1. Product core introduction

Welcome to the 304 Stainless Steel Black Hexagon Socket Cup Head Headless Screws product page created exclusively for you by HomeDIYer. These screws are tailor-made for home DIY enthusiasts, covering M3, M4 and M5 sizes, which can meet your fastening needs in all kinds of small projects. Whether you are making delicate handmade jewelry, repairing household objects or assembling personalized furniture models, these screws will be your reliable connection partner. Made of high-quality 304 stainless steel with stylish black finish, they not only have excellent rust-resistant performance, but also add a unique texture and professional atmosphere to your DIY works, so that your creativity can be easily realized and you can enjoy the fun and sense of achievement brought by DIY.

2. The main characteristics of the product

1. High-quality 304 stainless steel: 304 stainless steel is chosen as the raw material, this material has good corrosion resistance, can effectively resist the erosion of water vapor, oxidation and other factors in daily life, to ensure that the screws remain good performance and appearance after long-term use, there will be no rust, corrosion caused by the damage or loosening, to provide a long-lasting and stable fastening guarantee for your DIY projects.

2. Black beautiful and durable coating: the surface is treated with a special black coating, which not only makes the screws look more fashionable and beautiful, but also further enhances their abrasion and corrosion resistance with various materials and styles of DIY works. This coating has strong adhesion and is not easy to peel off, even in the case of frequent use and friction, it can remain intact and extend the service life of the screws.

3. Advantage of hexagonal cup head design: the design of hexagonal cup head facilitates the use of the corresponding hexagonal wrench for operation, compared with the traditional screwdriver slot head, it can withstand greater torque and is not easy to slip the silk phenomenon, so that you can tighten or loosen the screws with more ease and save energy, and at the same time, it also improves the precision and safety of the operation to ensure that the screws can be securely fixed in the required position.

4. Cup head headless delicate construction: headless design makes the screws flush with the connected surface after installation, there will be no protruding part to affect the overall appearance or cause scratching, collision and other problems, especially suitable for the appearance of demanding fine DIY projects, such as wooden crafts, small metal ornaments, etc., so that your work is more delicate and delicate, showing the professional level of production standards.

3. Product use scene

1.Small Furniture Assembly and Maintenance:When making small wooden furniture, such as bookshelves, jewelry boxes, children's tables and chairs, etc., M3, M4, M5 screws can be used to connect the various components, such as fixing the table legs to the tabletop, connecting the drawer guides to the cabinets and so on. Its high-quality materials and appropriate specifications can ensure that the furniture structure is stable, withstand the daily use of opening and closing, moving and other operations, while the black appearance can also be blended with a variety of wood colors, adding a simple and stylish atmosphere. These screws are also ideal for repairing old furniture, such as replacing loose connections, and can quickly restore the function and stability of the furniture.

2.DIY electronics production and modification: when you carry out DIY production of electronic products, such as homemade small speakers, intelligent equipment shell, electronic models, etc., need to fix the circuit board, shell, bracket and other components, this screws precision size and good conductivity (304 stainless steel with a certain degree of conductivity) to meet the requirements of the screws of electronic products. Its black appearance can also be compatible with the modern design of electronic products, making your work more professional and beautiful. When modifying and upgrading existing electronic products, such as replacing internal accessories or adding expansion modules, these screws can be easily disassembled and reinstalled, providing convenience for your creative modifications.

3.Creative handmade jewelry and crafts production: for handmade enthusiasts, the production of jewelry, metal crafts, leather products, etc., often need to use small and delicate screws to connect the various components. 304 stainless steel black hexagon socket head cap screws M3, M4, M5 specifications are suitable for these delicate handmade projects, they can be used to fix the beads, connecting the metal piece, an ornament accessories, etc., not only to ensure the firmness of the work, but also to ensure that the work is not only a good choice. etc. Not only can they ensure the firmness of the work, but the black screws match with all kinds of materials and colors to show unique creativity and style, adding a sense of high class and individual charm to your handmade jewelry.

4. Product use instructions

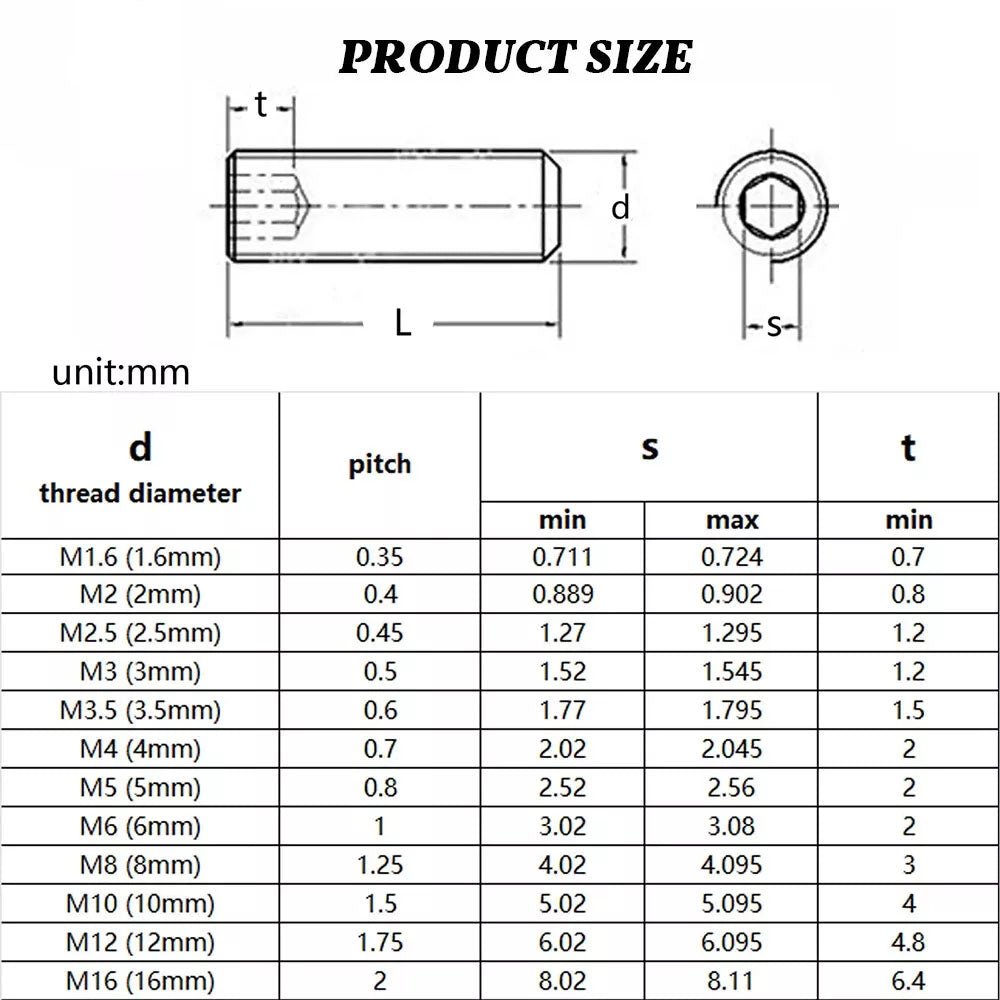

Tool preparation: According to the specifications of the screws (M3, M4, M5), choose the corresponding size of hexagonal wrench and make sure that the dimensional accuracy of the wrench matches perfectly with the hexagonal recess of the screws, in order to avoid slipping of threads or damage to the screws and wrenches in the process of operation. Check the wrench before use to make sure it is clean and undamaged, if necessary, clean the wrench and make sure its head is not deformed or worn.

Installation steps:

Pre-assemble the parts to be connected according to the design requirements, make sure that the holes of each part are aligned and that there are no debris or burrs in the holes, so as not to affect the smooth installation of the screws.

Select the appropriate specification (M3, M4 or M5) 304 stainless steel black hexagon socket cup head screws without head, align the threaded end with the holes of the pre-assembled parts, gently rotate the screws, so that they initially enter the holes, be careful not to exert too much force, so as not to damage the threads.

Insert the hexagonal wrench into the hexagonal groove of the screw, keep the wrench perpendicular to the screw, and then gradually apply an even force in a clockwise direction to tighten the screw slowly. During the tightening process, pay attention to the bonding of the connected parts to ensure that they fit tightly without gaps or deflections. For different materials and usage scenarios, the degree of tightening can be adjusted appropriately, but it is generally recommended to tighten until the parts are firmly connected and will not cause deformation or damage to the material due to over-tightening. For example, when connecting wooden parts, tighten until the surface of the wood is slightly concave; when connecting metal parts, the torque can be increased appropriately according to the actual situation, but care should be taken to avoid exceeding the material's tolerance limit.

Disassembly method: If you need to disassemble the screws, first use the hexagonal wrench to insert into the hexagonal groove of the screws, and then slowly rotate the wrench in the counterclockwise direction to gradually loosen the screws. During the disassembly process, it is also necessary to keep the wrench perpendicular to the screw and apply force evenly to prevent the screw from slipping or being damaged by the connected parts due to uneven force. When the screws are loosened to a certain extent, you can remove them by hand, and take care to save the removed screws so that they will not be lost.

Caution:

Before using the screws, carefully check their appearance for any defects, cracks, coating flaking, etc. If there is any quality problem, please do not use them, and you should contact our customer service for replacement in time.

Avoid exposing the screws to strong acids, alkalis and other highly corrosive chemical environments, although 304 stainless steel has a certain degree of corrosion resistance, long-term exposure to these substances may affect the performance and appearance of the screws.

When storing screws, it is recommended that they be placed in a dry, ventilated, light-proof environment, and it is best to use ziplock bags or small boxes to categorize and store them, and mark the specifications and models of the screws, so that the next time you use them, you can quickly find the products you need. At the same time, it is necessary to avoid mixing screws with other metal items to prevent scratching and collision, resulting in coating damage or screw deformation.