1. Product core introduction

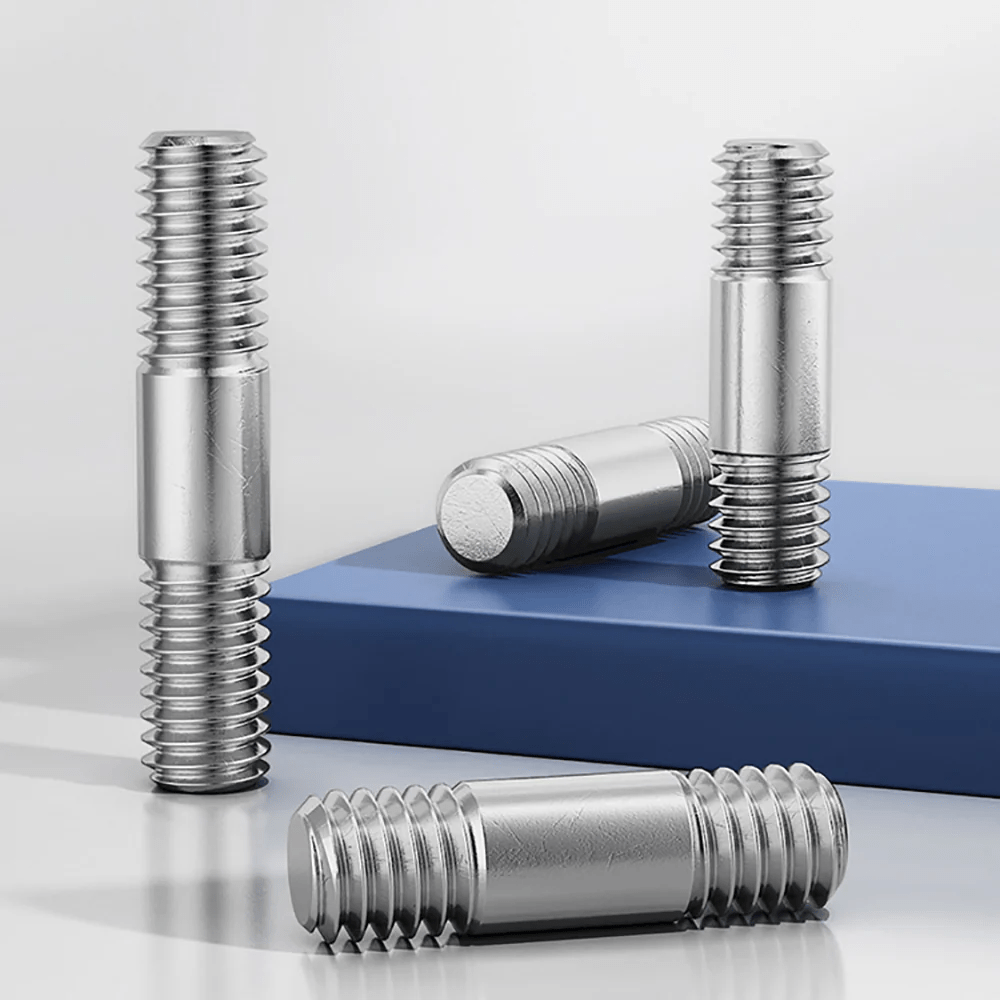

HomeDIYer's 304 stainless steel double-head eyebolt is available in M3, M4, M5, and M6 specifications. Carefully crafted with selected high-quality 304 stainless steel, it meets the diverse connection needs of home DIY enthusiasts and small projects with its excellent performance, and is a reliable guarantee for stable and efficient connection.

2. The main characteristics of the product

1. High-quality material: Made of 304 stainless steel, it has good corrosion resistance and high strength, can be used stably in common environments, is not easy to rust and deform, and can maintain good mechanical properties for a long time to ensure the reliability of the connection.

2. Various specifications: It provides different specifications of M3, M4, M5, and M6. According to different connection objects and load requirements, the appropriate size can be accurately selected to meet various connection scenarios from fine to conventional.

3. Double-head design: The unique double-head structure has threads on both ends, which is convenient for direct connection with different components without the need for intermediate adapters, greatly simplifying the installation process and improving work efficiency.

3. Product use scene

1. Small furniture assembly: When assembling small tables, chairs, shelves and other furniture, choose bolts of corresponding specifications according to the thickness and load-bearing capacity of the components to enhance the stability of the furniture structure and improve the use experience.

2. Electronic equipment repair: When repairing electronic devices such as mobile phones and tablets, small-size bolts such as M3 and M4 can be used to fix internal components, and 304 stainless steel will not corrode electronic components.

3. Model making: When making models such as aircraft models and car models, bolts of different specifications can be used to connect various components to meet the model's requirements for connection strength and precision, making the model stronger and more refined.

4. Product use instructions

1. Installation preparation: According to project requirements, accurately select bolts of appropriate specifications from M3 to M6. Prepare matching screwdrivers, wrenches and other tools. Carefully clean the surface of the connecting parts, remove dust, oil, etc., to ensure that the connection surface is clean and flat.

2. Installation steps: Slowly screw one end of the bolt into the threaded hole of the fixed part and tighten it to a moderate degree. Align the part to be connected with the other end of the bolt, screw on the nut, and then tighten it evenly with a tool to achieve the appropriate degree of tightening.

3. Debugging and operation: After the installation is completed, gently shake the connection part to check whether it is firm and whether there is any sign of looseness. For load-bearing parts, perform a simple load-bearing test. If any problems are found, adjust or replace the bolts in time