1. Product core introduction

HomeDIYer's 304 stainless steel lifting eye bolts are available in M5, M6, M8, M10, and M12 specifications. Made of high-quality 304 stainless steel, they are designed to meet the lifting and fixing needs of home DIY enthusiasts in different scenarios, and are also suitable for some small industrial scenarios with low load-bearing requirements.

2. The main characteristics of the product

1. High-quality material: 304 stainless steel is selected, which has excellent corrosion resistance. It can be used stably in a humid and corrosive environment, is not easy to rust, and ensures the safety and reliability of long-term use.

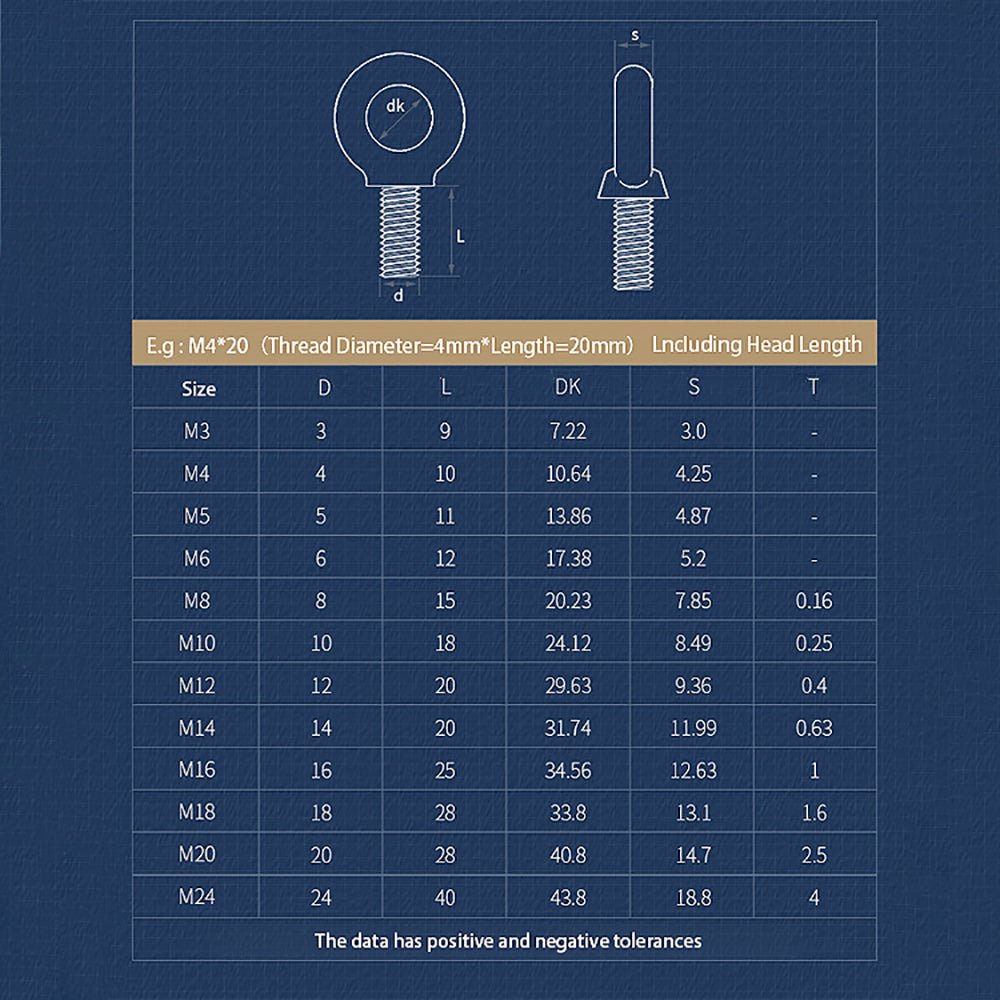

2. Rich specifications: M5, M6, M8, M10, M12 are provided. According to different lifting weights and connection requirements, the appropriate size can be flexibly selected to meet diverse practical applications.

3. Exquisite design: The unique lifting ring design is convenient for connection with various lifting tools such as ropes and hooks, and can effectively disperse the stress during lifting to ensure the stability of the lifting process.

4. Fine craftsmanship: After fine processing, the thread is standard and precise, and it fits tightly with the nut. The surface of the lifting ring is smooth and flawless, ensuring that there will be no loosening, slipping and other problems during use.

3. Product use scene

1. Daily use in the home: In the home, when moving small furniture, hanging heavy decorative paintings, etc., you can choose the appropriate specifications of the lifting ring bolt according to the weight of the object, and easily achieve lifting and fixing.

2. Model making and display: During the model making process, it is used to fix model parts or hang display models. Different specifications can be adapted to models of different sizes and weights to meet the needs of model enthusiasts.

3. Small equipment installation: In small industrial or office environments, it is used to install and fix some small equipment, such as small ventilation fans, small lamps, etc., to provide reliable connections.

4. Product use instructions

1. Installation preparation: According to the weight of the lifting or fixing object and actual needs, select the appropriate specifications of the eyebolt. Prepare suitable installation tools such as wrenches.

2. Installation steps: Screw the threaded end of the eyebolt into the pre-drilled threaded hole, and tighten it slowly and evenly with a wrench to ensure that the bolt is firmly installed and the eyebolt can rotate freely without looseness.

3. Debugging and operation: After the installation is completed, perform a simple test lift or check the fixation. Observe whether the connection between the eyebolt and the object is firm and whether the eyebolt rotates smoothly. If there is any problem, adjust or replace the bolt in time.