1. Product core introduction

HomeDIYer, a reliable brand in the home DIY field, brings you this high-quality 304 Stainless Steel Plum Blade Pan Head Machine Screw.

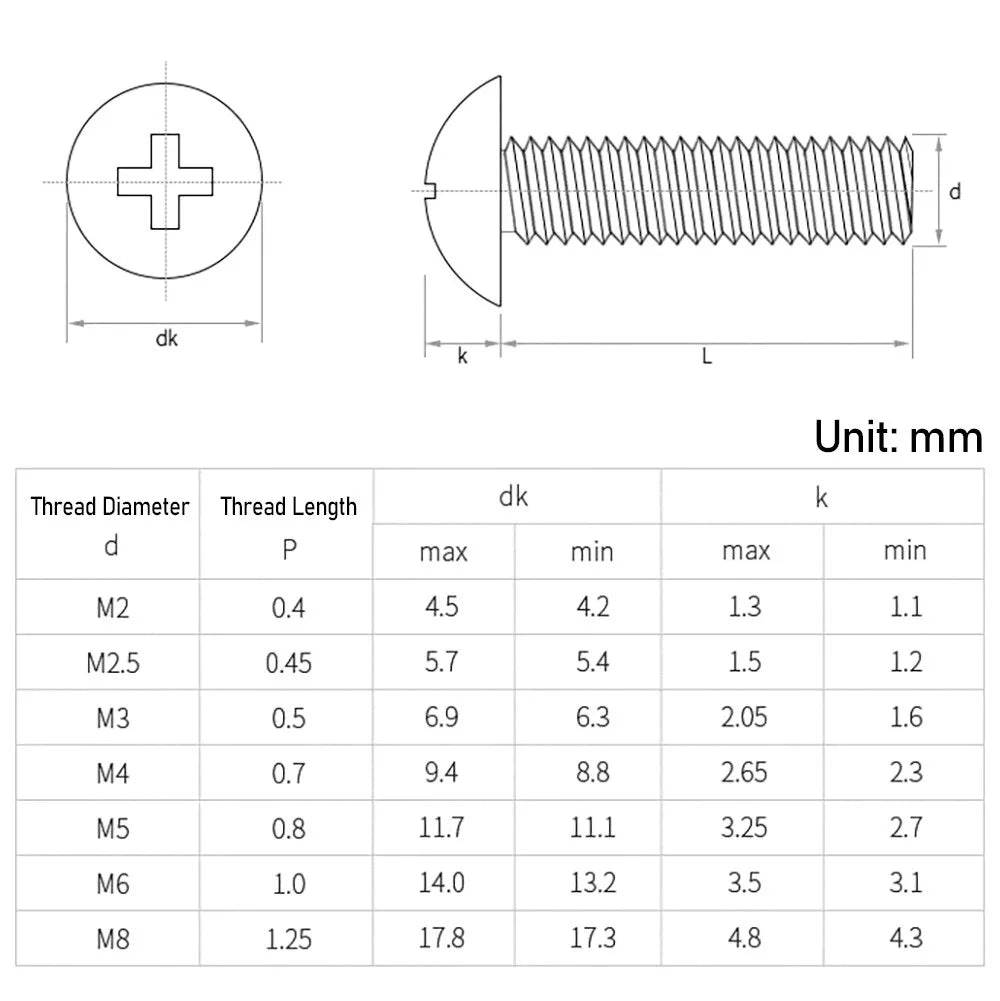

It comes in a wide variety of sizes, from fine M2 to practical M6, and in lengths ranging from 3mm for compact sizes to 100mm for extended lengths. This wide selection of specifications makes it possible for you to find the right screws to meet your complex home DIY needs and provide a solid foundation for your creative realization, whether you are carrying out delicate DIY projects for electronic devices or building large furniture frames.

Made of genuine 304 stainless steel, through strict quality control and professional processing technology, to ensure that each screw has a stable and reliable performance, is an indispensable high-quality accessory for your home DIY projects.

2. The main characteristics of the product

High-quality 304 stainless steel material: made of 304 stainless steel with excellent corrosion resistance, able to resist the erosion of water vapor, humidity and common chemicals in daily life, maintain the structural integrity and appearance of the screws in the long term, effectively prevent rust, greatly extend the service life of the product, so that your DIY work lasts as long as the new, reducing the cost of maintenance in the later stage.

Advantage of plum groove design: the unique design of plum groove, compared with the traditional cross slot or one-slot, can provide greater torque transmission, the contact between the screwdriver and the slot is more tight and stable, effectively preventing the phenomenon of slippage, so that the screws are easier and more convenient to install and dismantle, even in the narrow space or the need for a larger tightening force, can be operated smoothly, to improve the efficiency of your DIY work.

Plate head design features: The plate head design is not only beautiful and generous, but also has a larger contact area with the fixed parts, which can disperse the pressure and reduce the damage to the surface of the material, and at the same time, in some application scenarios that need to withstand greater tension or pressure, the plate head can provide better support and stability to ensure a more reliable tightening effect, making your DIY projects more solid and durable.

Precise Dimensional Tolerance: Advanced production equipment and exquisite manufacturing process ensure that the dimensional tolerance of the screws in diameter (M2 - M6) and length (3mm - 100mm) is controlled within a very small range, and the screws work accurately and precisely with other components, fit tightly and are not easy to loosen after installation, which greatly improves the overall quality and safety of your DIY projects and ensures the structural stability of your creative works.

3. Product use scene

DIY and Repair of Electronic Devices: When making small electronic device housings, assembling circuit boards or repairing electronic products, the smaller sizes of M2 - M4 screws can accurately fix each component without damaging the precision electronic components due to oversized screws. The non-magnetic properties of stainless steel will not interfere with the normal operation of electronic equipment, ensuring stable performance, safety and reliability of electronic equipment, to meet the detailed requirements of your electronic DIY projects.

Furniture assembly and restoration: Whether you are assembling wooden tables, chairs, cabinets or restoring old furniture, M3 - M6 screws can play an important role. Longer lengths (e.g. 50mm - 100mm) can be used to penetrate thick wood and securely fasten it, ensuring the stability of the furniture structure, while shorter lengths are suitable for fixing thinner sheets or connecting small furniture components such as drawer guides, cupboard hinges, etc. The M3 - M6 screws can be used in a wide range of applications, from furniture assembly to restoration. The design of the plum blossom disk head not only ensures the firmness of the connection, but also adds to the beauty of the furniture, making your home decor more exquisite.

HOME DECOR INSTALLATION: When installing decorative picture frames, wall-mounted shelves, curtain rails and other home decorations, these screws come in a variety of sizes to perfectly fit different decorative pieces and installation scenarios. Smaller M2 and M2.5 screws can be used to fix thin and light decorative panels, while M4 - M6 screws can be used to bear heavier decorative items or penetrate the wall for fixing to meet different load-bearing requirements. Plum groove's ease of operation makes you more relaxed during the installation process, and quickly creates a warm, comfortable, beautiful and generous home environment.

HANDMADE CREATIVE DIY PROJECTS: If you are passionate about handmade metal, wood or plastic crafts, this screw can be used as a key element for connecting and fixing. For example, to make a metal model, the screws can firmly connect the various metal parts, and its stainless steel luster and the shape of the disk head can also add a sense of sophistication to the work; in wooden handicrafts, you can also choose the appropriate specifications according to the needs of different parts, showing your unique craftsmanship and creative talent.

4. Product use instructions

Tool preparation: According to the specifications of the screws (M2 - M6), choose the corresponding size of the plum screwdriver to ensure that the bit fits closely with the screw's plum groove, to avoid slipping or damaging the screw groove and screwdriver bit due to the inappropriate bit that leads to unscrewing.

Preparation before installation: Before installation, clean the surface of the parts to be fixed, remove dust, oil, rust and other impurities to ensure that the screws and parts can be in close contact with each other to obtain good friction and fastening effect. For harder materials (such as metal) or parts that need to withstand greater pressure, it is recommended to pre-drill pilot holes slightly smaller than the diameter of the screws according to the diameter of the screws using the appropriate drill bit, which can reduce the resistance when screwing in the screws to prevent cracking of the material and to ensure that the screws can be installed smoothly in place.

Installation process: Align the screws with the pre-drilled holes (if any) or directly with the position where they need to be fastened, and then slowly screw them in perpendicular to the mounting surface using a plumb bob screwdriver. At the beginning, gently rotate the screwdriver so that the screws initially enter the holes. After confirming that the screws are correctly positioned and perpendicular, gradually increase the force and tighten the screws smoothly. In the process of tightening, pay attention to the uniform application of force to avoid uneven force resulting in screw tilt or damage to the threads. For longer screws, if you feel that it is difficult to screw in, you can pause appropriately to check whether the screw is vertical and whether there is any foreign matter blocking the hole, if necessary, you can use a small amount of lubricant to assist screwing in, but be careful to avoid the lubricant contamination of other parts.

Removal steps: If you need to remove the installed screws, also use a suitable screwdriver, insert the head of the screwdriver into the screw's plum groove, and then rotate the screwdriver counterclockwise to gradually loosen the screw. During the loosening process, keep the screwdriver perpendicular to the screw to prevent slipping. If the screw is tight because it has not been disassembled for a long time or because it is rusty, you can drop in an appropriate amount of rust remover or lubricant and wait for a few moments before attempting to unscrew it, which will help to minimize the resistance during disassembly and protect the threads of the screws and the mounting parts from damage.