1. Product core introduction

HomeDIYer 304 Stainless Steel Spring Pins, known as Sellock Roll Pins, are available in sizes M6 - M12. Made from durable 304 stainless steel, they offer excellent resilience and reliable fastening properties, making them ideal for a variety of scenarios that require secure and flexible connections. Whether it's a DIY project or an industrial machine, rely on these Sellock Roll Pins to get the job done right.

2. The main characteristics of the product

High-quality 304 stainless steel material: 304 stainless steel is selected, which has good corrosion resistance, can maintain stable performance in humid, acid and alkali and other harsh environments, not easy to rust, effectively extend the service life, suitable for outdoor facilities, marine engineering, chemical equipment and other occasions with high requirements for rust prevention, to ensure that the connection parts of the long term reliability, reduce maintenance costs and failure of the connection due to rust, and at the same time, ensure the It also ensures the safety and stability of the product in various environments.

Outstanding elasticity design: the unique elastic structure enables it to expand and contract within a certain range, effectively cushioning and absorbing vibration, reducing wear and fatigue damage between components, and improving the stability and durability of the connection; and in the process of installation, it can better adapt to the size tolerance of the holes to ensure a close fit, and it is not easy to be loosened or fall off even when subjected to shocks or vibrations, which provides a strong guarantee for the normal operation of the equipment. Provide a strong guarantee for the normal operation of the equipment.

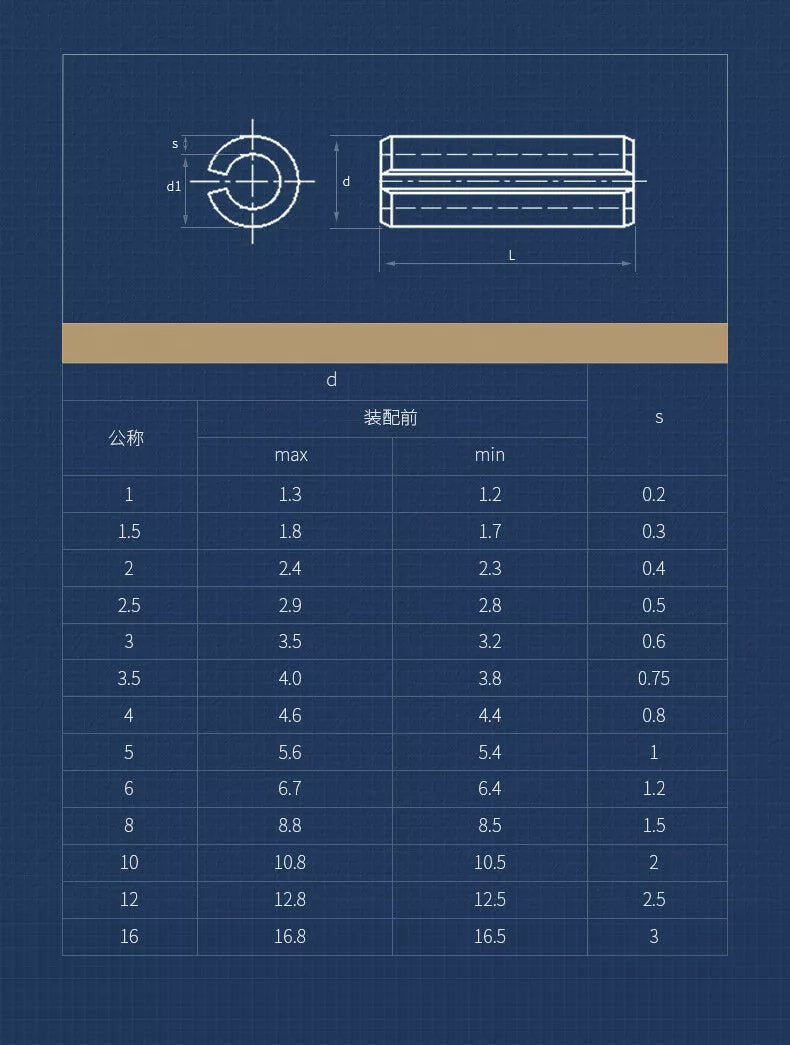

Accurate dimensions: M6 to M12 sizes are available to meet the needs of different hole diameters and application scenarios, to ensure precise matching with various mechanical components, whether small precision instruments or large industrial equipment, you can find the appropriate specifications of spring pins, to achieve accurate and reliable connection, improve installation efficiency and overall performance of the equipment, to provide users with a wider range of application options.

Reliable fastening performance: After careful design and manufacture, the spring pin can rely on its own elasticity to generate enough friction after inserted into the hole, firmly fixed in the hole, effectively preventing the relative displacement between the components to ensure the firmness of the connection; even when subjected to large tensile force, pressure or shear force, it can also maintain a stable connection state, reducing the risk of failure due to connection loosening, suitable for applications that require high connection reliability. This reduces the risk of failure due to loosening of the connection and is suitable for applications requiring high reliability of the connection, such as automotive engines, machine tools, aerospace components, etc.

3. Product use scene

DIY and small machinery repair: in family DIY projects, such as making small metal crafts, repairing bicycles, assembling furniture, etc., it can be used to connect various metal parts, and its elasticity and easy-to-install features can meet the creative and practical needs of DIY enthusiasts, complete various connection tasks conveniently and quickly, and at the same time, let the user experience the fun and sense of achievement of mechanical connection during the process of doing it. In the maintenance of small machinery, such as power tools, gardening equipment, etc., it is used to replace damaged pins and restore the normal operation of the equipment, and its reliable performance and a variety of specifications can quickly solve mechanical problems, improve the maintenance efficiency, and reduce the cost of maintenance.

Industrial manufacturing and mechanical equipment: In industrial production, it is widely used in the manufacture and assembly of various mechanical equipment, such as automobile manufacturing, machine tool processing, engineering machinery and other fields. In the automotive engine piston pin connection, transmission gear fixed, machine tool spindle box parts connection, etc., the spring pin can withstand the vibration and impact generated by the high-speed operation, to ensure the precise fit between the components and stable operation, improve the efficiency of industrial production and product quality, to provide strong support for the development of industrial manufacturing.

Aerospace and high-end equipment: in the field of aerospace, used for aircraft engine parts connection, landing gear assembly, aircraft structural components fixed and other key parts, its high strength, corrosion resistance and reliable elasticity of the connection to meet the aerospace equipment on the lightweight, high-performance and high-reliability of the strict requirements to ensure flight safety; in the manufacture of high-end equipment, such as precision instruments, satellite equipment, etc., spring pins of high precision and stability also play an important role. In high-end equipment manufacturing, such as precision instruments, satellite equipment, etc., the spring pin's high precision and stability also plays an important role in ensuring the normal operation and precise control of the equipment under complex working conditions, and enhancing the technical level and international competitiveness of China's high-end equipment.

4. Product use instructions

Installation Steps:

Align one end of the spring pin with the hole of the connected part, and then gently tap the other end of the spring pin with an appropriate tool (such as a punch and hammer) to gradually insert it into the hole. During the insertion process, pay attention to keep the spring pin vertical and avoid skewing it to ensure that it is evenly stressed and enters the hole smoothly.

When the spring pin is fully inserted into the hole, its ends should be flush with or slightly below the surface of the connected part (according to the specific application requirements). At this point, the spring pin can be slightly adjusted with the appropriate tool to make it in the right position in the hole to ensure a tight and stable connection.

After the installation is complete, check the connection area of the spring pins to see if the spring pins are in place, if the fit between the spring pins and the connected parts is tight, and if there are any signs of loosening. If necessary, the reliability of the connection can be tested by applying some external force (such as tension, pressure or torque), but be careful not to exceed the rated load capacity of the spring pin.

Precautions for use:

In the process of use, regularly check the connection parts of spring pins for signs of looseness, deformation, corrosion, etc. Especially after the equipment has been subjected to vibration, shock, temperature changes or long-term use, if problems are found, corresponding measures should be taken in time to repair or replace them, so as to ensure that the connection is safe and reliable. For spring pin connections in industrial equipment and important structures, it is recommended to carry out regular inspection and maintenance in accordance with the maintenance cycle of the equipment, such as cleaning the connection part, checking the elasticity performance, measuring the change of aperture, etc., in order to ensure the normal operation of the equipment and the stability of the structure.

Avoid spring pins to bear loads exceeding their rated carrying capacity. In the process of design and use, the specifications and models of spring pins should be reasonably selected in accordance with the actual working conditions to ensure that they can withstand the applied tensile force, pressure or shear force, and to prevent overloading leading to breakage, deformation of the spring pins or damage to the connected parts, which will lead to safety accidents. At the same time, be careful to avoid the use of spring pins in harsh environmental conditions (such as high temperature, high humidity, strong acid and alkali, etc.), so as not to affect its performance and life, if necessary, should take appropriate protective measures (such as the use of high-temperature or corrosion-resistant spring pins of stronger material, the connection part of the protective treatment, etc.).

When storing and handling the spring pins, avoid collision, extrusion or friction with other hard objects to prevent the surface of the spring pins from being scratched, deformed or damaged, which will affect its appearance and performance. Store the spring pins in a dry, ventilated environment free of corrosive gases and keep them properly so that they can be kept in good condition for the next use. At the same time, we should pay attention to the different specifications of the spring pin classification storage, easy to find and use, to avoid confusion specifications and lead to installation errors, affecting the use of the effect and safety.