1. Product core introduction

HomeDIYer 304 Stainless Steel Square Washers in sizes from M3 to M20 are made of durable 304 stainless steel and provide excellent support and stability for a wide range of fastening applications, whether for DIY projects or industrial use. Increase the reliability of your connections with our square washers.

2. The main characteristics of the product

High-quality 304 stainless steel material: 304 stainless steel is selected, which has good corrosion resistance, can maintain stable performance in humid, acid and alkali and other harsh environments, not easy to rust, effectively extend the service life, suitable for outdoor facilities, marine engineering, chemical equipment and other occasions with high requirements for rust prevention, to ensure that the connection parts of the long term reliability, reduce the connection failure caused by rust, and at the same time, ensure that the product in a variety of At the same time, it ensures the safety and stability of the product in various environments and reduces the maintenance cost.

Precise square design: the standard square shape can provide a larger contact area, compared with round washers, it can better disperse the pressure and prevent the connected parts from local deformation or damage during the fastening process, especially suitable for connection scenarios that require high flatness and stability, such as the installation of precision instruments, mechanical equipment, etc., to ensure that the solidity and reliability of the connection.

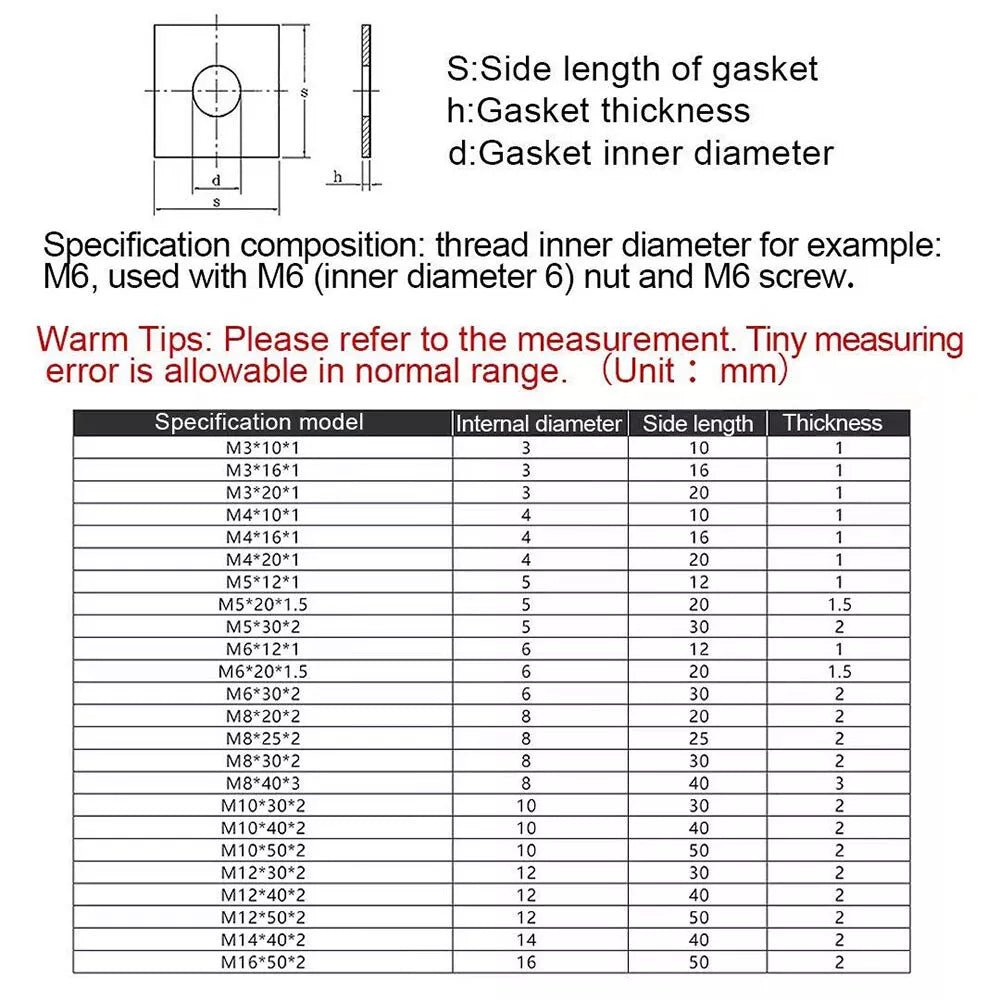

Wide range of sizes: covering M3 to M20 specifications to meet the diverse needs of different hole diameters and application scenarios, whether it is small electronic equipment or large industrial machinery, you can find the appropriate square washer specifications, to ensure that the precise match with a variety of standard bolts and nuts, to achieve accurate and efficient connection, providing users with a wider range of application options to facilitate the user's flexibility to choose according to the actual situation. Good surface treatment: the surface of the washer is made of high quality material.

Good surface treatment: the surface of the washer is finely treated, smooth and flat, without burrs, cracks and other defects, not only beautiful and generous, but also in the process of installation can reduce the wear and tear on other parts, but also helps to improve the friction between the washer and the connected parts, further enhance the stability and reliability of the connection, so that the installation process is more smooth.

3. Product use scene

DIY and home maintenance: in home DIY projects, such as assembling furniture, repairing bicycles, installing electrical equipment, etc., can be used in various bolt connection parts, its larger contact area can effectively disperse pressure, prevent furniture parts from being crushed, electrical equipment loosening and other problems, improve the quality and safety of DIY works; in home maintenance, such as repairing doors and windows, fixing the staircase handrail, etc., the use of 304 Stainless steel square washers can quickly solve the problems arising from unstable connections, extend the service life of household goods, reduce safety hazards, and provide protection for home life.

Automobile manufacturing and maintenance: in the process of automobile manufacturing, used for the engine, chassis, body and other parts of the bolt connection, can withstand the process of automobile driving vibration, bumps and impacts, to ensure that the connection between the parts is close and stable, to prevent the connection from loosening and cause failure, to ensure the overall structural strength of the car and driving safety; in automobile maintenance, such as replacement of engine parts, repair of the suspension system, etc., square In automotive maintenance, such as replacing engine parts, repairing the suspension system, etc., the square washer is an important accessory to ensure the quality of maintenance, which can effectively improve the reliability of the connection, reduce the risk of failure of the car in the subsequent use, and improve the durability of the car.

Industry and manufacturing: In industrial production, they are widely used in the manufacture and assembly of various mechanical equipment, such as machine tools, engineering machinery, power equipment and other fields. In the spindle box of machine tools, feeding mechanism, square washers are used to fix the bolt connection of key components to ensure the machining accuracy and stability of the machine tool; in the engine and hydraulic system of engineering machinery, it can prevent the bolt from loosening due to vibration and impact, ensure the normal operation of the equipment, improve the efficiency of industrial production and product quality, and provide strong support for the development of industrial manufacturing.

4. Product use instructions

Installation Steps:

Place the square washer on the bolt hole of the connected part, make sure the centre of the washer is aligned with the centre of the bolt hole.

Insert the bolt and screw on the nut, use appropriate tools to tighten the nut gradually according to the specified tightening torque, during the tightening process, pay attention to keep the bolt in a vertical state, avoid skewing, and make sure that the washer is uniformly loaded and closely fits on the surface of the connected parts to give full play to its role in dispersing pressure and stabilising the connection.

After the tightening is completed, check the connection parts to see whether the washers are installed in place, whether the nuts or bolts are tightened firmly, and whether there are any signs of loosening. If necessary, the tightening torque can be checked again to ensure the reliability of the connection.

Precautions for use:

In the process of use, regularly check whether the square washers in the connection parts have signs of loosening, deformation, corrosion, etc., especially after the equipment has been subjected to vibration, shock, temperature changes or long-term use, if problems are found, corresponding measures should be taken in a timely manner to repair or replace, to ensure that the connection is safe and reliable. For the connections in industrial equipment and important structures, it is recommended to carry out regular inspections and maintenance in accordance with the maintenance cycle of the equipment, such as cleaning the connection parts, checking the wear and tear of the gaskets, and testing the stability of the connections, etc., in order to ensure the normal operation of the equipment and the stability of the structure.

Avoid the square washer to withstand loads exceeding its design bearing capacity, in the design and use of the process, should be based on the actual working conditions of a reasonable choice of washer specifications and models, to ensure that it can withstand the applied pressure, tension and shear force, to prevent overloading resulting in damage to the washer, the failure of the connected parts, triggering a safety accident. At the same time, attention should be paid to avoid the use of square washers in harsh environmental conditions (such as high temperature, high humidity, strong acid and alkali, etc.), so as not to affect its performance and life, if necessary, should take appropriate protective measures (such as the use of high temperature or corrosion-resistant gasket material, protection of the connection parts, etc.).