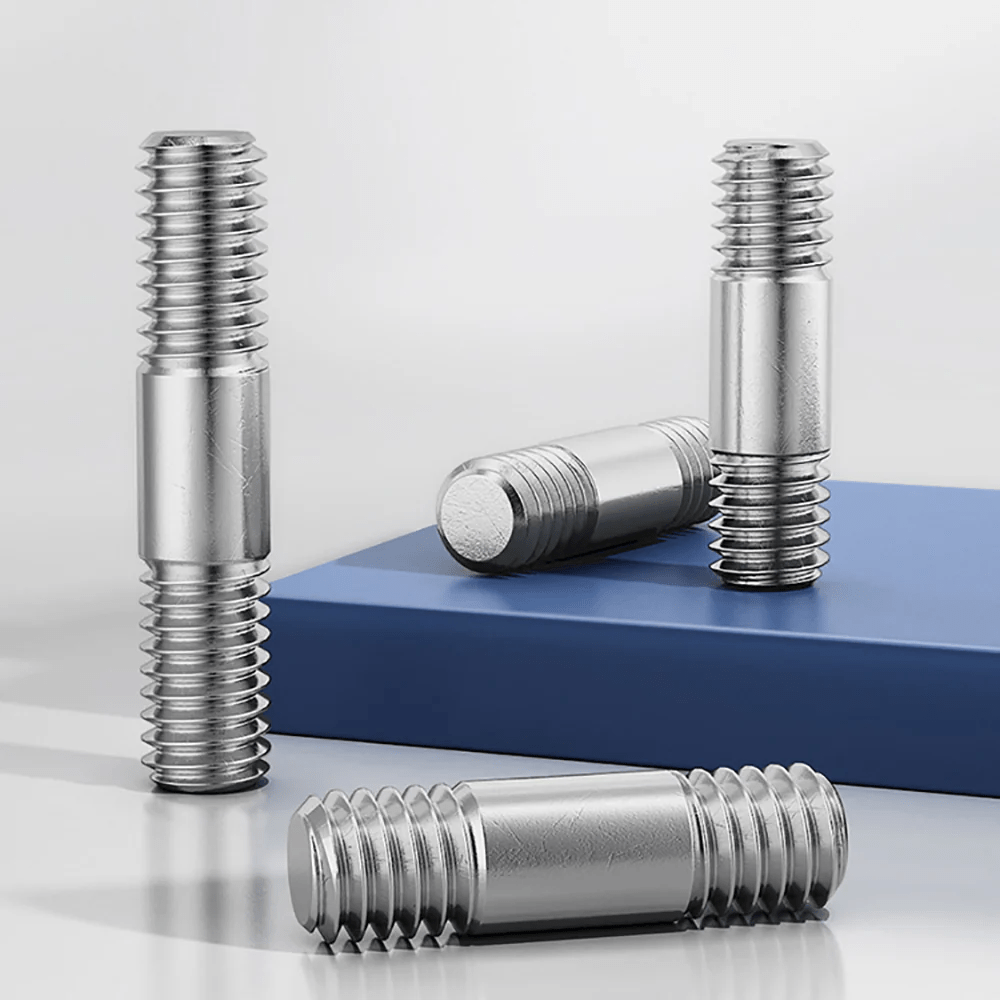

1. Product core introduction

316 stainless steel double end screws (eye bolts) are available in M6, M8, M10, M12, M14, and M16. Made of high-quality 316 stainless steel, it is designed to meet the connection needs of home DIY enthusiasts in different projects. It is a practical and reliable hardware accessory.

2. The main characteristics of the product

1. High-quality material: 316 stainless steel is selected, which has excellent corrosion resistance, high temperature resistance and high strength. It can be used for a long time in harsh environments, is not easy to rust or deform, and ensures the stability of the connection.

2. Multiple specifications: M6-M16 are provided to meet the needs of screw sizes for different projects. Whether it is small furniture assembly or large equipment fixation, suitable specifications can be found.

3. Double-head design: The unique double-head structure is convenient for connection with other components in different scenarios, without the need for additional adapters, simplifying the installation process and improving work efficiency.

4. Exquisite workmanship: After fine processing, the threads are clear and regular, and fit tightly with the nuts to ensure a firm connection and not easy to loosen.

3. Product use scene

1. Home decoration: When installing household items such as chandeliers, wall cabinets, curtain rods, etc., double-head screws of different specifications can be used to fix them to ensure that the items are firmly installed and safe to use.

2. Outdoor facility installation: If you install outdoor clothes drying racks, awnings, fences, etc., 316 stainless steel can withstand harsh outdoor environments and ensure the stability and durability of the facilities.

3. Mechanical maintenance and assembly: During the maintenance and assembly of small machinery, stud screws can be used to connect different parts to meet the connection requirements of mechanical structures.

4. Product use instructions

1. Installation preparation: Select stud screws of appropriate specifications according to project requirements. Prepare corresponding tools, such as wrenches, screwdrivers, etc. Clean the surface of the connecting parts to ensure cleanness and flatness.

2. Installation steps: Screw one end of the stud screw into the threaded hole of the fixed part and make sure it is tightened. Then align the other part to be connected with the other end of the screw, screw on the nut, and use the tool to tighten the nut to make the connection tight.

3. Debugging and running: After the installation is completed, check whether the connection parts are firm and whether there is any looseness. For connections that bear weight, perform appropriate load-bearing tests to ensure safety and reliability.