1. Product core introduction

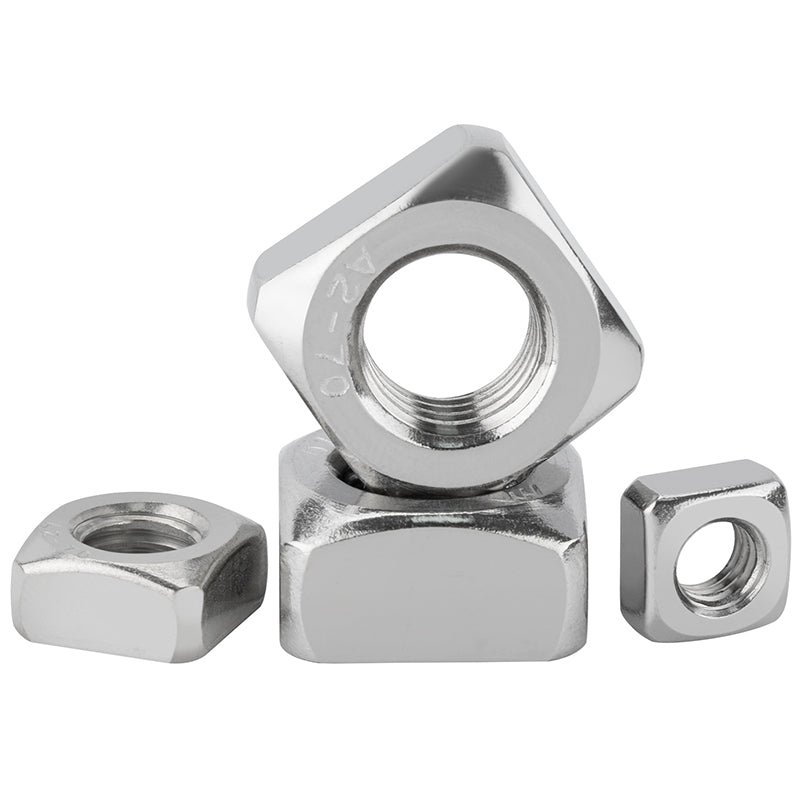

1.HomeDIYer is proud to introduce a range of 316 Stainless Steel Square Nuts, customized for the home DIY enthusiast. These nuts play a key role in your creative projects, whether you're building elaborate furniture or repairing and assembling small equipment, providing a solid and reliable connection solution.

We select high-quality 316 stainless steel, a material known for its excellent corrosion resistance in the stainless steel family. Careful design and rigorous manufacturing processes ensure that each nut delivers outstanding performance, from tiny M3 sizes to larger M12 sizes, to meet the needs of your diverse projects and provide a solid foundation for your DIY creations.

2. The main characteristics of the product

1.Top grade 316 stainless steel material: 316 stainless steel contains molybdenum element, which makes its corrosion resistance far more than ordinary stainless steel. Whether it's in a humid kitchen, a bathroom full of moisture, or outdoors on a terrace and other harsh environments, it can effectively resist various chemicals, such as salt spray, acid and alkali solutions, etc. It ensures that the nut maintains its structural integrity and aesthetics for a long period of time, and provides a long-lasting and durable connection for your DIY projects.

2. Unique square design: The square shape design is not only for aesthetics, but also for its functionality. Compared with round nuts, the four flat surfaces of square nuts can form a larger contact area with the connected parts, which evenly disperses the pressure during the tightening process and reduces the pressure on the surface of the parts, effectively preventing the connected parts from being dented or deformed. At the same time, the larger friction force also makes the nut more stable after tightening, less likely to be loosened by vibration or external force, providing reliable stability for your DIY structure.

3. Highly accurate size specification: Every size from M3 to M12 is manufactured according to strict international standards, ensuring that the dimensions of the nuts are precise and accurate. The threaded part is processed with very high precision, and fits closely with the supporting bolts, which is smooth and fluid when installing, and can be easily screwed in without excessive force, avoiding installation difficulties or poor connection caused by dimensional deviation, greatly improving your DIY work efficiency and installation quality.

4. Excellent mechanical properties: 316 stainless steel gives the nut excellent mechanical properties, with high strength and toughness. It performs excellently when withstanding various tensile, pressure and shear forces, and can meet the strict requirements of different DIY projects for connecting parts. Whether it is used for fixing the frame of heavy furniture, connecting precision mechanical equipment, or building outdoor metal structures, it can stably and reliably play its connecting role to ensure the safety and reliability of the whole structure.

3. Product use scene

HIGH-END FURNITURE CUSTOMIZATION & RESTORATION: 316 Stainless Steel Square Nut is the ideal connector when making high quality wood or metal furniture, such as luxury dining tables, exquisite cabinets, classical style bedding, etc.. Its excellent corrosion resistance ensures that furniture used in wet environments such as kitchens and bathrooms will not suffer structural or aesthetic damage due to rusting of the nut. In furniture restoration, if you want to improve the quality and durability of old furniture, use this product to replace the original ordinary nuts, can make the furniture a new look, and at the same time extend its service life, show your taste and craftsmanship.

Precision equipment maintenance and DIY electronic equipment production: For the maintenance of some small precision equipment, such as home computers, small audio equipment, precision instruments, etc., as well as the production of DIY electronic equipment, such as homemade small drones, intelligent robots, etc., the high precision and reliability of these nuts are crucial. They can ensure the tight connection between various parts inside the equipment, the stability of electronic signal transmission and the normal operation of the equipment, providing solid hardware support for your scientific and technological creative projects.

Outdoor facilities construction and maintenance: When you build awnings, barbecue grills, small gardening tool racks and other facilities in the outdoor area, the corrosion resistance and high strength of 316 stainless steel square nuts show their advantages. It can resist the erosion of rain, sunshine, wind and sand and other natural factors, and keep the structure stable for a long time without replacing the nuts frequently, which saves you the maintenance cost and time, and lets you enjoy the fun of outdoor life to the fullest.

4. Product use instructions

Accurate selection of specifications: Carefully select the right size of 316 stainless steel square nuts according to the size of the bolts involved in your DIY project and the specific application scenario. Ensuring that the thread size of the nut matches the bolt exactly is a critical step in ensuring a strong and stable connection. You can refer to the design drawings of the project or actually measure the hole diameter and thread parameters of the connected parts to select the most suitable nut size.

Preparation before installation: Before installing the nuts, make sure to thoroughly clean the surface of the connected parts to remove oil, dust, rust and other impurities. Wipe with a clean cloth or clean with a suitable detergent to ensure that the surface is flat, smooth and dry. This will significantly improve the friction and fit between the nut and the component, resulting in a tighter and more reliable connection, and will also help to prevent corrosion problems due to impurities remaining after the nut has been installed.

Correct installation method: Align the nut with the threaded end of the bolt, and gently screw it in by hand for a few turns first to ensure that the threads are initially aligned and screwed in smoothly. Then, choose a suitable tool, such as a wrench or socket wrench (according to the size of the nut and tightening requirements to choose the appropriate specifications), in accordance with the clockwise direction to gradually tighten the nut. During the tightening process, the force should be applied evenly to avoid excessive force on one side resulting in thread damage or deformation of the connected parts. For some projects with strict requirements on tightening torque, it is recommended to use a torque wrench and operate according to the specified torque value to ensure the safety and reliability of the connection. Generally speaking, the tightening torque required for nuts of smaller sizes (e.g. M3 - M6) is relatively small, while those of larger sizes (e.g. M8 - M12) require a larger tightening torque, but the specific value should be adjusted appropriately according to the actual use, material and structure of the components and other factors.

Regular inspection and maintenance: After completing the installation of the nut, carefully check whether the connection part is firm and whether the nut is tightened in place. The stability of the connection can be initially tested by gently shaking or applying certain external force. During long-term use, especially in harsh environments or projects with frequent stress, the nuts should be checked regularly. If any sign of looseness is found, the nut should be tightened in time. If rust or corrosion spots are found on the surface of the nut, it should be cleaned and maintained according to the actual situation, and replacement of the nut should be considered if necessary, in order to ensure the structural safety and normal operation of the whole DIY project.