1. Product core introduction

The 70C Stainless Steel Copper Core Pulley is an efficient helper in many areas of operation. Whether it's for the precise transmission of industrial machinery or the smooth opening and closing of doors and windows in the home, the unique combination of materials allows it to fulfil its role. In creative DIY projects, it can also be cleverly combined with fittings to expand the boundaries of functionality and provide key support for the realisation of complex design ideas, making it the ideal choice for those who are looking for outstanding performance.

Combining the durability of stainless steel with the excellent thermal conductivity of copper cores, they are crafted with meticulous care to provide powerful power and stable operation for all types of equipment and devices.

2. The main characteristics of the product

Ultra-durable: stainless steel shell provides excellent corrosion resistance, can withstand moisture, acid and alkali and other harsh environments, whether it is outdoor machinery and equipment for a long time by the wind and rain, or the kitchen, bathroom and other high humidity areas of the door and window pulley applications, are not easy to rust, wear and tear, to ensure long service life.

Efficient conduction: the built-in copper core gives full play to copper's excellent thermal conductivity, in some mechanical devices involving power transmission or the need for rapid heat dissipation, such as small motor-driven drive systems, electronic equipment cooling fan pulley components, can effectively conductive current, emit heat, to ensure the stable operation of the equipment, to avoid overheating failures.

Smooth operation: high-precision bearing design with high-quality surface treatment of the pulley, making the pulley in operation with minimal friction, smooth rotation, whether it is high-speed industrial equipment, or daily frequent opening and closing of doors and windows, can easily achieve smooth and silent operation, enhance the user experience.

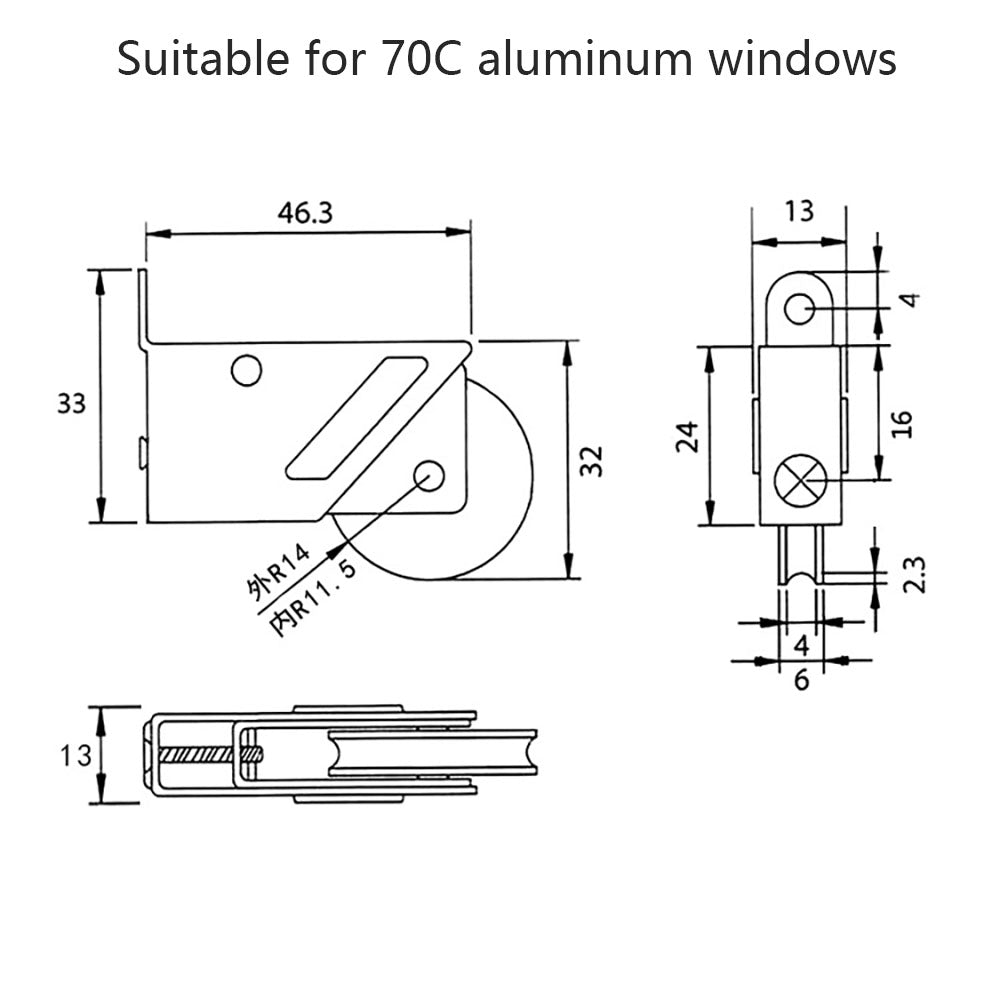

Precise adaptation: provide a variety of specifications and sizes to meet the needs of different machinery, doors and windows, whether it is heavy-duty transmission of large-scale industrial machinery, or the fine installation of various types of doors and windows in the family home, commercial premises, you can find a perfect match for the model, strong versatility.

Stable load-bearing: with strong load-bearing capacity, thanks to the high strength of stainless steel and optimised structural design, it is not easy to be deformed when it is under greater pressure, ensuring the stable operation of equipment, doors and windows, etc., and will not be jammed or shaken due to the compression of heavy loads.

3. Product use scene

Industrial Manufacturing: In automated production lines, packaging machinery, textile machinery and other equipment, it is used as a transmission pulley to accurately transfer power and ensure the efficient operation of production lines. Its durability can reduce equipment downtime for maintenance, and the conductivity of the copper core can meet the demand for power transmission of some equipment, and improve the overall production efficiency.

Home decoration: used for residential entry doors, balcony sliding doors, kitchen windows, etc. pulley system, so that the doors and windows open and close easily, noiselessly and smoothly, to enhance the comfort of living. Stainless steel material is fearless of kitchen oil, bathroom water vapour, maintaining long-term beauty and performance, escorting for home life.

Commercial places: shopping mall window display doors, shop rolling doors, office space partition doors and windows, etc., frequent opening and closing operations on the pulley is very demanding. The durability and smoothness of this product can ensure smooth business operations, reduce maintenance costs and enhance the experience of customers and employees.

DIY creative projects: In the homemade electric tool car, small wind generator, smart home mobile devices and other projects, the combination of pulleys and fittings, the use of fittings to build a framework, pulleys to achieve the mobile or transmission function, to create personalised, high-tech works, to show the unique creativity and hands-on ability.

4. Product use instructions

Installation Preparation: According to the application scenario, determine the model and specification of the required pulley; prepare suitable installation tools, such as screwdrivers, wrenches, pliers, etc.; clean up the installation area, remove dust, oil, debris, etc., to ensure that the mounting surface is smooth and clean; if used for DIY projects with pipe fittings, prepare pipe fittings, connectors and sealant in advance.

Installation steps: For mechanical drive pulleys, according to the equipment manual, install the pulleys on the corresponding drive shafts, brackets and other parts, use screws, nuts and other fixings to ensure that the pulleys are installed securely, with good concentricity and smooth rotation. For door and window pulleys, remove the old pulley (if any), align the mounting bracket of the new pulley with the reserved holes at the bottom or side of the door or window, and tighten the screws with a screwdriver to ensure that the pulley is perpendicular to the track and can roll freely; after the installation is completed, gently push the door or window to test the smoothness, and if there is any jamming, fine-tune the installation position. If it is used for DIY project, cut and polish the pipe fittings according to the design, build the frame, then install the pulley in the predetermined position, connect the pipe fittings with pipe connectors and apply sealant to ensure firmness, pay attention to the overall balance and stability.

Attention: Avoid overloading in daily use to prevent damage to the pulley; regularly check the operation of the pulley to see whether there are debris stuck, whether the bearings are dry, whether the screws are loose, etc., and if there is any problem, clean, lubricate or fasten it in time; try to avoid contacting the pulley with corrosive substances such as strong acids and strong alkalis in order to prevent damage; when it is used in high-speed equipment, pay attention to the temperature of the equipment, and ensure that the copper core dissipates heat properly.

Maintenance: Regularly clean the surface of the pulley and the surrounding area to remove dust, oil, available wet cloth or a small amount of cleaner to assist; if the pulley rotation appears dry, you can add appropriate drops of lubricating oil; if there is wear and tear, paint, etc., timely replacement or make-up paint, in order to maintain a good appearance and performance.