1. Product core introduction

The A2 Stainless Steel Wire Rope Clamp U-bolt, in sizes from M2 to M20, is a heavy duty wire rope clamp. Made from high quality A2 stainless steel and metal, it is designed to provide a reliable and secure fastening solution for wire rope. Suitable for a variety of applications where strength and durability are critical, it ensures a stable and long-lasting connection to meet your fastening needs.

2. The main characteristics of the product

High-quality A2 stainless steel: A2 stainless steel is used, which has excellent corrosion resistance, can maintain stable performance in humid, acid and alkali and other harsh environments, and is not easy to rust, which effectively extends the service life, and is suitable for offshore engineering, chemical equipment, outdoor construction facilities and other occasions with very high requirements for rust prevention, to ensure that the connection part of the steel wire rope is reliable for a long time, and to reduce the maintenance cost and the failure of the connection due to rust, and at the same time, to ensure the safety and stability of the product under various environments. At the same time, it ensures the safety and stability of the product in various environments, providing a solid guarantee for long-term use in outdoor or harsh working conditions.

Heavy-duty U-bolt design: The unique U-bolt design provides strong clamping force and stability, effectively preventing the wire rope from loosening, slipping or falling off in the process of use.The U-shape structure can be better adapted to the rounded contour of the wire rope to make it fit tightly and evenly distribute the pressure to enhance the firmness of the connection, especially suitable for applications that are subjected to large tensile forces and impacts, such as cranes, cranes, bridge pulling ropes and other heavy equipment, such as the application of the U-bolt design, to ensure the safety and stability of the product under various circumstances, Bridge cable ties and other heavy equipment wire rope fastening, to protect the safe operation and efficient work of the equipment.

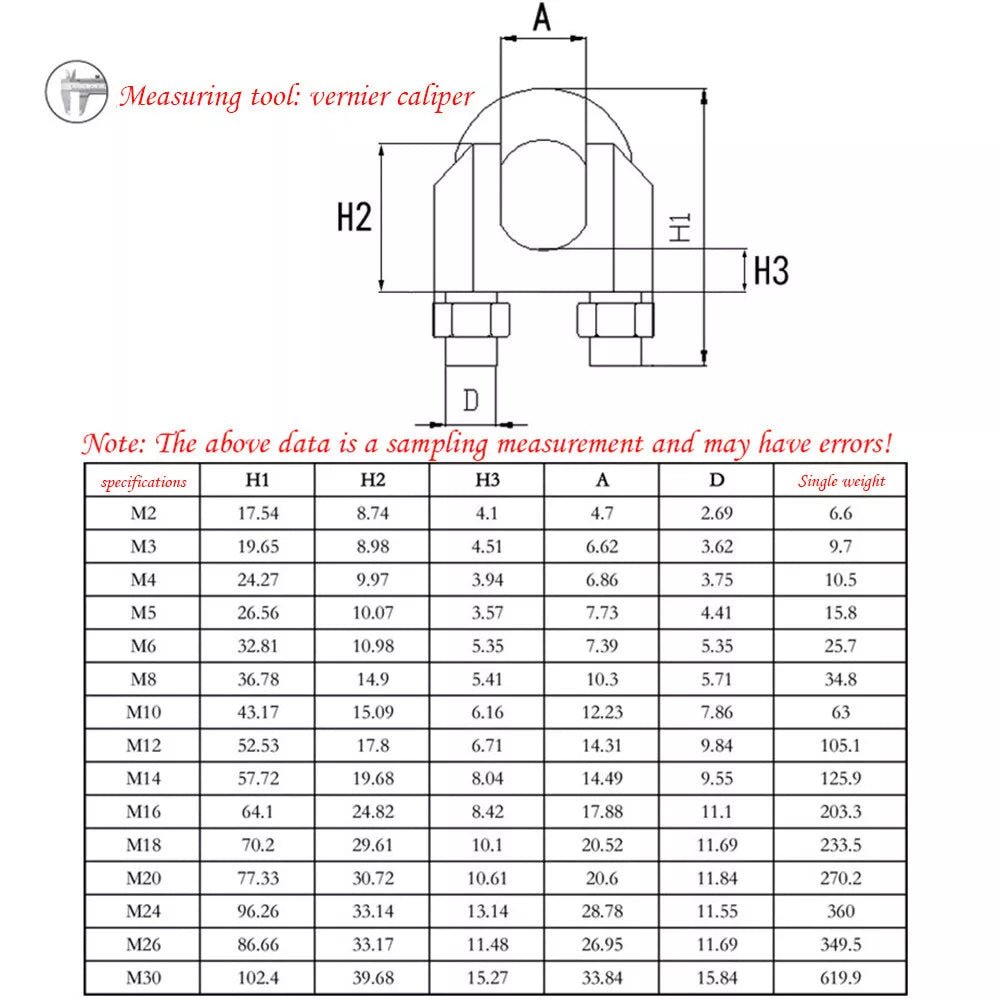

Wide range of sizes and specifications: M2 to M20 multiple sizes to meet the fastening needs of different diameter wire rope, whether it is small and thin rope for light equipment, or large and thick rope for heavy industrial machinery, you can find an accurate match of specifications to facilitate the user to choose according to the actual application scenarios, to ensure that with a variety of sizes of ropes to ensure the perfect fit, improve the efficiency of the installation and quality of the connection, to achieve accurate and reliable tightening effect, and to ensure the safe operation and efficient work of equipment. Achieve precise and reliable fastening effect to meet diversified project requirements.

Sturdy and durable structure: the overall structure is sturdy and durable, after careful design and manufacture, the components are closely matched with each other, and can withstand high working pressure and frequent use frequency, not easy to deformation, damage or fatigue failure, with high reliability and stability, to provide strong support for the long-term stability of the wire rope connection, reduce the risk of safety accidents due to the failure of the connecting parts, suitable for areas that have very high requirements for safety, such as mining, mining, and other industries. It is suitable for fields with very high requirements for safety, such as mining, aerial work, large-scale building construction, etc.

3. Product use scene

Industrial manufacturing and engineering construction: in all kinds of industrial manufacturing fields, such as iron and steel mills, machinery factories, shipyards, etc., used for cranes, lifts, conveyor belts, tower cranes and other equipment wire rope connection and fixation, to ensure that the equipment in the high-intensity, high-frequency working conditions, the wire rope connection is firm and reliable, to ensure the safety and smoothness of the production process; in the large-scale engineering construction projects, such as bridge construction, high-rise building construction, In large-scale engineering construction projects, such as bridge construction, high-rise building construction, port terminal construction, etc., it is used for the fastening of pulling ropes, spreaders, safety protection ropes, etc., to withstand huge tensile force and wind and other external forces, to provide a key guarantee for the smooth progress of the project and the stability of the structure, to meet the stringent requirements of the industrial and engineering fields of the wire rope fastening.

Transportation and logistics industry: in the field of transportation, such as car trailers, train freight wagons, ship mooring, etc., used to fix the bundling ropes of goods and connect the traction ropes, to ensure the safety and stability of the goods in the process of transport, to prevent accidents occurring due to the loosening of the ropes and the displacement of the goods, falling, etc.; in the logistic warehouse goods handling and loading and unloading equipment, such as forklift trucks, electric hoists, etc., also used for the connection of wire rope, to ensure the normal operation of the equipment and the stability of structures. In the cargo handling and loading and unloading equipments of logistics warehouse, such as forklift, electric hoist, etc., it is also used for the connection of wire ropes to ensure the normal operation of the equipments and the efficient operation, to improve the efficiency and safety of the logistics transport, and to adapt to the complex and changeable working environment and the carrying demand of the transport and logistics industry.

Outdoor adventure and extreme sports: in outdoor adventure activities, such as rock climbing, mountaineering, rappelling, high-altitude rope adventure, etc., used for the connection of safety ropes and fixed points, its high strength and reliability can provide life safety protection for the explorer, to withstand the weight of the human body and a variety of sudden impact of external forces; in the extreme sports events and training grounds, such as the racing circuit of the guardrail ropes to fix the paragliding traction ropes to connect, etc., also plays an important role in ensuring that the athletes and the training ground. It also plays an important role in ensuring that the ropes are firmly connected to the athletes in the process of high-speed and high-risk sports, providing safe and reliable equipment support for outdoor adventure and extreme sports enthusiasts, and meeting their stringent requirements for equipment performance.

4. Product use instructions

Installation steps:

Pass the wire rope through the curved part of the U-bolt, so that the wire rope is located in the centre of the groove of the U-bolt, make sure that the wire rope is not twisted, entangled or skewed inside the U-bolt, and then put the two halves of the wire rope clamp on the wire rope respectively, so that the direction of the opening of the clevis corresponds to the threaded end of the U-bolt.

For single-stranded wire rope, use suitable tools (such as wrenches) in accordance with the specified tightening torque to gradually tighten the bolts of the wire rope clamps, so that the clevis is tightly clamped to the wire rope, and pay attention to the tightening process to apply uniform force, to avoid unilateral uneven force leading to deformation or damage to the wire rope clamps; for multi-stranded wire rope, should be in accordance with a certain order of the sequential tightening of each of the rope clamps to ensure that each strand of the wire rope can be uniformly For multi-stranded wire rope, the wire rope clamps should be tightened in order to ensure that each strand of wire rope can be evenly clamped, and the spacing between the clevis meets the installation requirements, and the general spacing is about 6-8 times of the diameter of wire rope.

While tightening the wire rope clamps, pay attention to the surface state of the wire rope to ensure that the wire rope has not been excessively squeezed or damaged, if necessary, you can apply an appropriate amount of lubricant (e.g. graphite powder, petroleum jelly, etc.) on the parts of the wire rope in contact with the clevis, in order to reduce the friction and abrasion, but be careful to avoid lubricant contamination of other parts or affect the friction of the connection.

Finally, pass the threaded end of the U-bolt through the fixing point (e.g. the connecting ear plate of the equipment, the bracket, etc.) and use the nut and washer to tighten it to make sure that the U-bolt is firmly installed without loosening, and then check the connection between the wire rope clamps and the U-bolt again to make sure that the whole tightening system is safe and reliable, and conforms to the requirements for use.

Precautions for use:

In the process of use, regularly check whether the connection parts of wire rope clamps and U-bolts have signs of looseness, deformation, wear and corrosion, etc., especially after the equipment is subjected to vibration, impact, frequent load changes or long-term use, if problems are found, corresponding measures should be taken in time for repair or replacement to ensure that the connection is safe and reliable. For the wire rope connection in industrial equipment and important projects, it is recommended to carry out regular inspection and maintenance according to the maintenance cycle of the equipment, such as cleaning the connection parts, lubricating the threads, checking the clamping force of the clevis, etc., in order to prolong its service life and ensure the normal operation of the equipment.

Avoid the wire rope clamps and U-bolts to bear loads exceeding their rated carrying capacity. In the process of design and use, the specifications and models of the products should be reasonably selected according to the actual working conditions to ensure that they can withstand the applied tensile force, pressure or impact force, and to prevent overloading leading to fracture or damage of the parts, which may cause safety accidents. At the same time, attention should be paid to avoid the use of wire rope clamps and U-bolts in poor environmental conditions (such as high temperature, low temperature, strong wind, heavy rain, high humidity, etc.), so as not to affect its material properties and reliability of the connection, and if necessary, should take appropriate protective measures (such as selecting the material of high or low temperature resistance, increase the protective sleeve, etc.).

When storing and handling the wire rope clamps and U-bolts, avoid collision, extrusion or friction with other hard objects, so as to prevent the surface of the parts from being scratched, deformed or damaged, thus affecting their appearance and performance. Store the products in a dry, ventilated environment with no corrosive gases and keep them properly so that they can be kept in good condition when used next time. At the same time, pay attention to the classification of different specifications of the product storage, easy to find and use, to avoid confusing the specifications and lead to installation errors, affecting the use of the effect and safety.