1. Product core introduction

HomeDIYer aluminium flat head solid rivets are available in 2mm, 3mm, 4mm, 5mm, 6mm and 8mm diameters. Made from high quality aluminium, they offer excellent strength and durability, making them ideal for a variety of applications that require a reliable fastening solution. Whether it's a DIY project or industrial use, you can rely on this solid rivet to get the job done.

2. The main characteristics of the product

High-quality aluminium material: the choice of aluminium material, with the characteristics of light weight, easy to operate and transport, and at the same time have a certain degree of strength and corrosion resistance, can be in the general environment to maintain stable performance, not easy to rust, reduce the cost of maintenance, suitable for the weight requirements and environmental conditions are relatively mild occasions, such as aeromodelling, automotive interiors, electronic equipment shells and other fields, to ensure that the connection of the firmness of the at the same time, help to achieve the It can help to realise the lightweight design of the product while ensuring the firmness of the connection.

Advantage of solid structure: solid design gives it high strength and stability, able to withstand large tensile and shear forces, providing reliable fastening effect when connecting parts, ensuring that the connection parts are not easy to loosen or deform in the process of long-term use, suitable for structural components with high requirements for connection strength, such as metal frames, mechanical components, etc., providing a solid guarantee for the stable operation of the equipment or products.

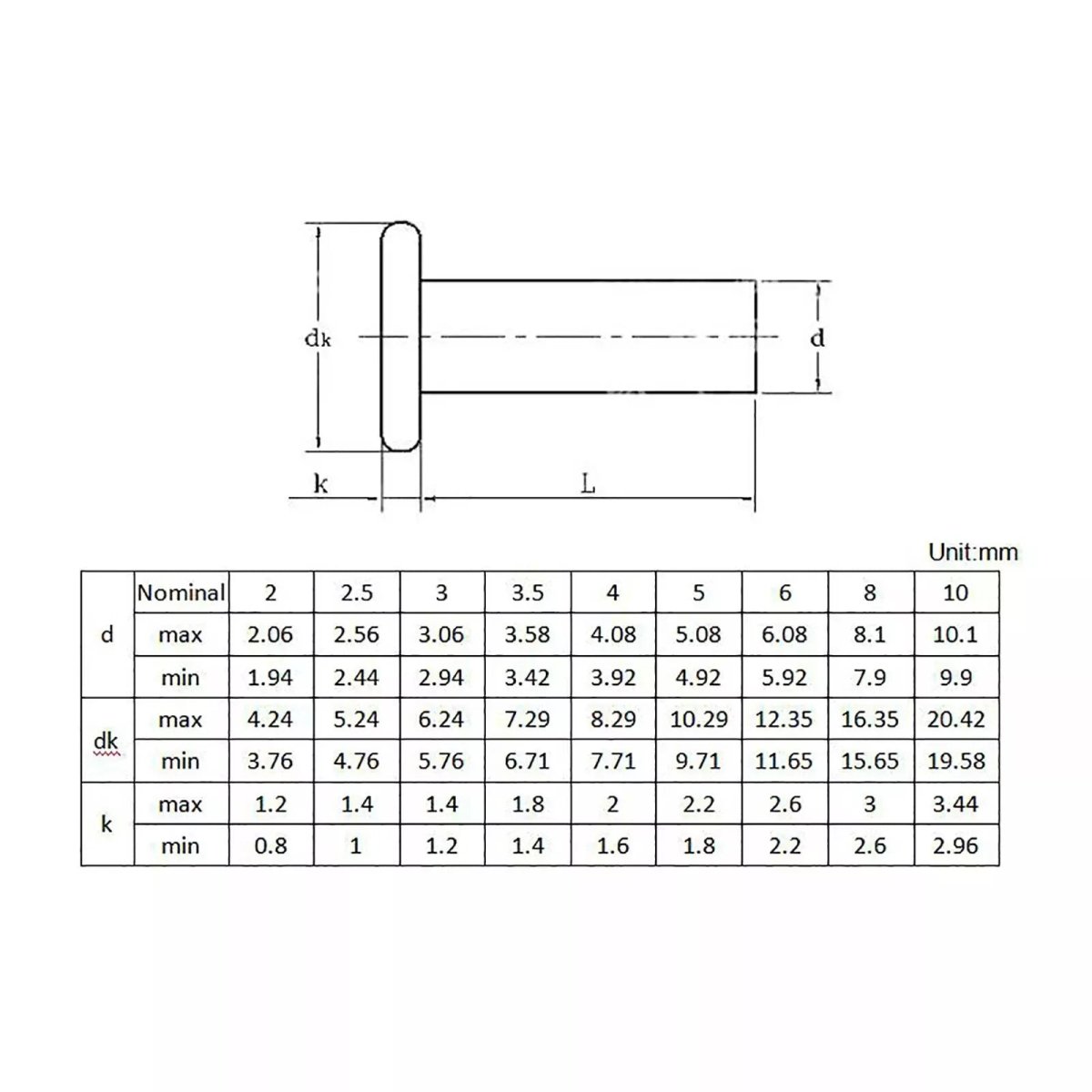

A variety of size options: provide from 2mm to 8mm diameter specifications to meet the requirements of different thickness and size of the plate connection needs, whether it is thin metal sheets or thicker structural components, can find the appropriate rivet specifications to ensure precise matching with the connected parts, to achieve a close and efficient connection, improve the efficiency of the installation and the quality of the connection to ensure the safe and stable operation of the equipment or products, providing users with a Provide users with a wider range of application options.

Flat head design is beautiful and practical: Flat head structure after riveting and the surface to be connected flush, the appearance of neat and beautiful, will not cause bulging or obstruction, especially suitable for occasions where the surface needs to be kept flat, such as precision instrument shells, furniture surface decorations, etc., not only to ensure that the connection of the firmness, but also does not affect the overall appearance and structure of the layout, to improve the overall quality of the product and the degree of sophistication, and at the same time, also facilitate the follow-up processing and surface coating and other operations.

3. Product use scene

DIY and home decoration: In home DIY projects, such as making metal crafts, repairing furniture, installing interior decorations, etc., it can be used to connect parts made of different materials, such as metal sheets, wood, plastic, etc., and its easy-to-operate and multi-size adaptability can meet various creative and practical needs, add personalised elements to home decoration, and also allow users to easily realise their own design and enjoy the fun and achievement of doing things; in small home decoration projects, it is used for fixing door and window frames, installing lamp brackets, etc., to ensure a firm and beautiful connection and enhance the quality and safety of the home environment. At the same time, it also allows users to easily realise their own design in the DIY process, enjoying the fun and sense of achievement; in small home improvement projects, it is used for fixing door and window frames, installing lamps and lanterns brackets, etc., to ensure a firm and beautiful connection and enhance the quality and safety of the home environment.

Electronic equipment and electrical appliances manufacturing: in the electronic equipment shell assembly, internal circuit boards fixed, heat sinks connected to play a role in its light weight and a certain degree of conductivity to help miniaturise electronic equipment and heat dissipation performance enhancement, while the solid structure ensures the reliability of the connection to prevent vibration or collision lead to loose parts, affecting the normal operation of electronic equipment; in the manufacture of electrical appliances, such as small fans, electric irons, etc., used to connect the metal outer shell, to ensure a firm and beautiful connection, enhance the quality and safety of home environment. In the manufacture of electrical products, such as small fans, irons, etc., it is used to connect the metal casing and internal structural components to meet the requirements of electrical products for structural strength and safety, and to ensure the stability and durability of the products in daily use.

Industry and manufacturing: in the automotive manufacturing, aerospace, machining and other industrial fields, used to connect metal structural components, fixed parts, etc., its strength and stability can withstand a variety of industrial production conditions and loads, to ensure the quality and performance of the product; in the automotive body assembly, used to connect the frame, doors, bonnets and other components, to ensure that the firmness and integrality of the body structure; in the aerospace model In aerospace model manufacturing, it is used to connect the wings, fuselage and other key parts, to meet the demand for lightweight and high-strength connections, providing strong support for the development of industrial manufacturing.

4. Product use instructions

Preparation before installation:

Check the appearance of the rivets for cracks, deformation, burrs and other defects to ensure that the product quality is intact. Also check whether the required specifications match the actual application scenarios, and replace them in time if there are any problems, so as not to affect the installation effect and performance.

According to the material, thickness and connection requirements of the connected parts, select the appropriate rivet specifications, and prepare the appropriate riveting tools, such as rivet guns, riveting machines, etc., to ensure that the tools are clean, sharp and function properly, so as to avoid damage to the rivets or the connected parts in the installation process.

Use a cleaning cloth or appropriate solvent to clean the surface of the connected parts, remove oil, rust, dust and other impurities, to ensure that the surface is dry, flat and smooth, to ensure that the rivets and the connected parts can be tightly adhered to each other, to achieve a good riveting effect and improve the stability and reliability of the connection.

Installation steps:

Insert the rivets into the pre-drilled riveting holes, make sure that the rivet's rod completely passes through the connected parts, and the head of the rivet is flush with the surface of the connected parts or slightly below the surface, and according to the actual need to reserve a certain length of the rivet rod in order to carry out the subsequent riveting operation.

Use riveting tools to squeeze or hammer the rivet stem, so that its head gradually deformed and outward expansion, filling the riveting hole, forming a solid connection. In the operation process, attention should be paid to controlling the strength and direction of riveting to ensure that the head of the rivet is uniformly deformed, to avoid eccentricity or excessive deformation, affecting the quality of the connection.

After the riveting is completed, the rivets are checked on the connected parts to ensure that the rivets and the connected parts are tightly combined without signs of loosening, and at the same time, check whether the connection of the connected parts is flat, if necessary, you can use the grinding tool on the head of the rivets to carry out the appropriate grinding process, so that the surface is smoother and more flat and in line with the use of the requirements.