1. Product core introduction

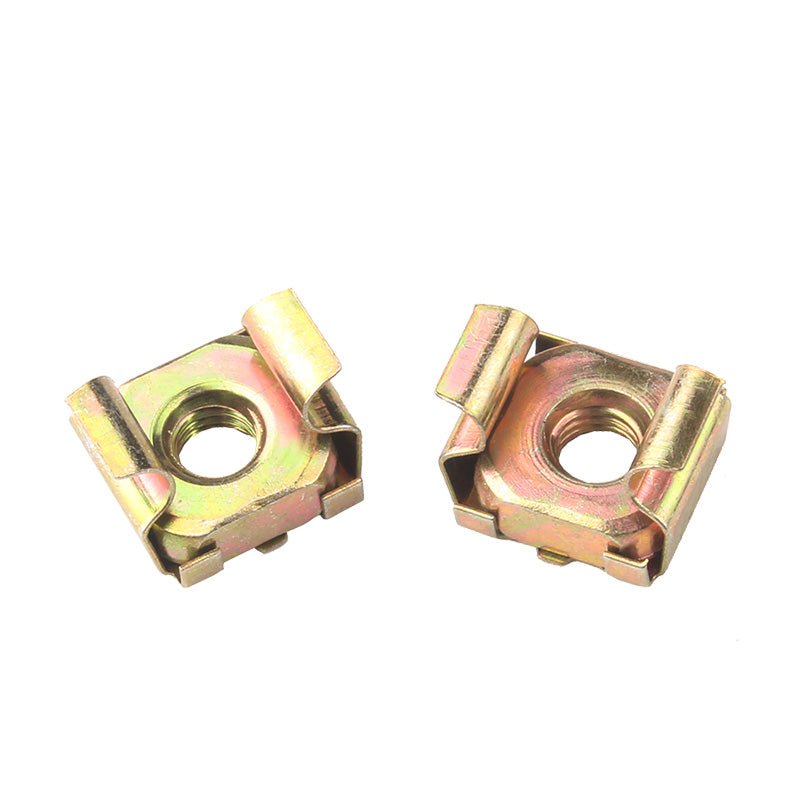

1.HomeDIYer brings practical and beautiful carbon steel color galvanized jam nuts for home DIY enthusiasts, which are ideal for all kinds of home decoration and craft projects.

2.Our snap nuts are made of high-quality carbon steel as the base material, and carefully treated with colorful zinc plating process, which makes them have good mechanical properties as well as excellent anti-rust ability and gorgeous appearance. The product is available in a wide range of sizes from M4 to M12, which can meet the needs of different projects for different nut sizes, whether it's small delicate furniture making or larger cabinet installation, you can find the right size, providing a solid and reliable connection solution for your DIY creations, so that your creations can easily come to fruition.

2. The main characteristics of the product

1.High Quality Carbon Steel Material: High strength carbon steel is chosen to ensure that the nut has enough strength and toughness to withstand certain tensile force, pressure and shear force, and maintain a stable connection performance in various DIY projects. This material undergoes strict quality testing to ensure that its internal organization is uniform and not prone to cracks or deformation, providing a solid base support for your work.

2. Colorful zinc plating process: The colorful zinc plating layer on the surface is a highlight of this product. The zinc plating not only effectively enhances the anti-rust ability of the nut, so that it can be used for a long time without rusting in humid, dusty and other complex environments, but also gives the nut a rich variety of color choices, such as fashionable silver, elegant gold, fresh blue, etc., according to your personal preferences and project style to match, to add a unique decorative effect for your DIY works, to enhance the overall aesthetic and personalized degree.

3. Convenience of cassette design: The unique cassette structure design makes the installation process extremely easy and fast. The cassette nut has a built-in elastic card, when installing, just insert the nut into the pre-drilled holes in the plate, the card will automatically snap into the plate, without additional complicated fixing steps, greatly saving your installation time and energy. This design is especially suitable for installing nuts in narrow spaces or difficult to maneuver areas, making DIY easier and more efficient, even for inexperienced novices.

4. Precise dimensional specifications: Every size from M4 to M12 is manufactured in strict compliance with international standards, ensuring that the dimensional accuracy of the nuts reaches a very high level. Whether it is the outer diameter, inner diameter or thickness of the nuts, they are all precisely processed and strictly inspected to ensure a perfect fit with the corresponding bolts or screws to realize a tight and stable connection. The precise dimensions not only improve the convenience of installation, but also effectively prevent loose connections, water and electricity leakage and other safety hazards caused by dimensional deviations, ensuring the quality and reliability of your DIY projects.

3. Product use scene

1. Furniture production and assembly: In the production of wooden or panel furniture, such as closets, bookshelves, cabinets, bedding, etc., carbon steel colored galvanized cassette nuts can be used to connect the various components, such as drawer guides, cabinet door hinges, shelf supports and other parts. Its colorful appearance can be coordinated with the color and style of furniture, adding a sense of sophistication. At the same time, the card design is convenient to install in the narrow space inside the furniture, so that the furniture assembly process is more efficient and effective, and the strong connection can ensure that the furniture in daily use to withstand a variety of open and close, load and other operations without loosening or damage to the situation.

2. Home decoration installation: For the installation of home decorations, such as picture frames, mirrors, wall-mounted storage racks, etc., this nut can also play an excellent role. The colorful galvanized appearance can be integrated with the decorative style of the home environment and play a beautiful decorative effect. The use of card nut for fixing, not only easy to install, but also to ensure that the decorations are firmly hung on the wall, do not have to worry about falling damage, for your home space to add a warm and comfortable atmosphere and personalized decorative elements.

3. Electrical equipment repair and installation: in some small electrical equipment shell repair or homemade small electrical equipment assembly process, these nuts can be used to fix the shell of the equipment, circuit board bracket and other components. The strength of the carbon steel material can meet the requirements of electrical equipment on the connecting parts, color galvanized layer of anti-rust properties can prevent rust and corrosion due to humid environments or electrical components leakage and other factors leading to corrosion of the nut, thus affecting the normal operation and service life of the equipment. The card-type design also facilitates quick installation and disassembly in the limited space inside the electrical equipment, which is convenient for maintenance and debugging work.

4. Product use instructions

1. Selection of specifications: According to the size of the bolts or screws used in your DIY project, as well as the thickness and material of the parts to be connected, carefully select the appropriate specifications of the carbon steel colored zinc-plated cassette nuts. Ensure that the inner diameter of the nut fits closely with the outer diameter of the bolt or screw, and consider whether the length and width of the tabs of the jam nut are suitable for insertion into the pre-drilled holes of the parts to be connected, so as to ensure firmness and stability of the installation. You can refer to the specification table attached with the product or consult the professional hardware sales staff to get the accurate specification selection suggestions.

2. Preparation for installation: Before installing the cassette nut, check whether the size of the pre-opened hole of the connected parts meets the requirements, and the wall of the hole should be smooth and even without burrs or debris, so as not to affect the insertion and fixing effect of the nut. If the hole wall is rough or uneven, sandpaper or file can be used for proper grinding and trimming. At the same time, clean up the oil, dust and impurities on the surface of the connected parts to ensure a clean and tidy surface, which can improve the friction and adhesion between the nut and the parts and make the connection more solid and reliable.

3. Installation method: align the selected specifications of the card nut with the pre-opened hole on the connected part, make the opening direction of the nut consistent with the installation direction, and then gently press the nut into the hole with your fingers or an appropriate tool until the card of the nut is completely stuck in the hole wall. During the press-in process, be careful to keep the nut in a vertical position to avoid skewing or twisting. If you encounter insertion difficulties, do not force it, you should check whether the pre-opened hole is too small or clogged with foreign objects, and promptly clean or trim before trying to insert it again. After the installation is completed, you can gently pull the nut to check whether it is firmly installed and whether the card is completely clamped.

4. Inspection and maintenance: After completing the installation of the nut, check the whole connection part to ensure that the nut is installed in place and the connection is tight without loosening. In the course of daily use, regularly check the condition of the nut, especially in projects that are often subject to vibration, collision or humid environment. If the nut is found to have signs of loosening, it should be tightened in time; if the galvanized layer on the surface of the nut is scratched, flaked or rusted, etc., it can be partially repaired using antirust paint of the corresponding color to maintain the beauty and rustproof performance of the nut. At the same time, avoid using sharp or hard objects to hit the nut directly, so as not to damage its structure and surface plating.