🔩Jack Nuts Threaded Inserts - Blind Spider Nut Rivnuts M4 M5 M6 M8 | HomeDIYer

Create strong, reusable threaded holes in thin materials with our professional jack nuts (also known as spider nuts or rivnuts)! These innovative blind threaded inserts install from one side only, making them perfect for automotive panels, sheet metal, plastics, and hollow doors where the backside is inaccessible. Bright zinc plated for corrosion protection. Available in M4, M5, M6, and M8 thread sizes.

🚗Perfect for Automotive & DIY Projects: Jack nuts are the go-to solution for adding sturdy threads to thin vehicle body panels, plastic components, and hollow-core materials where traditional nuts can't be installed.

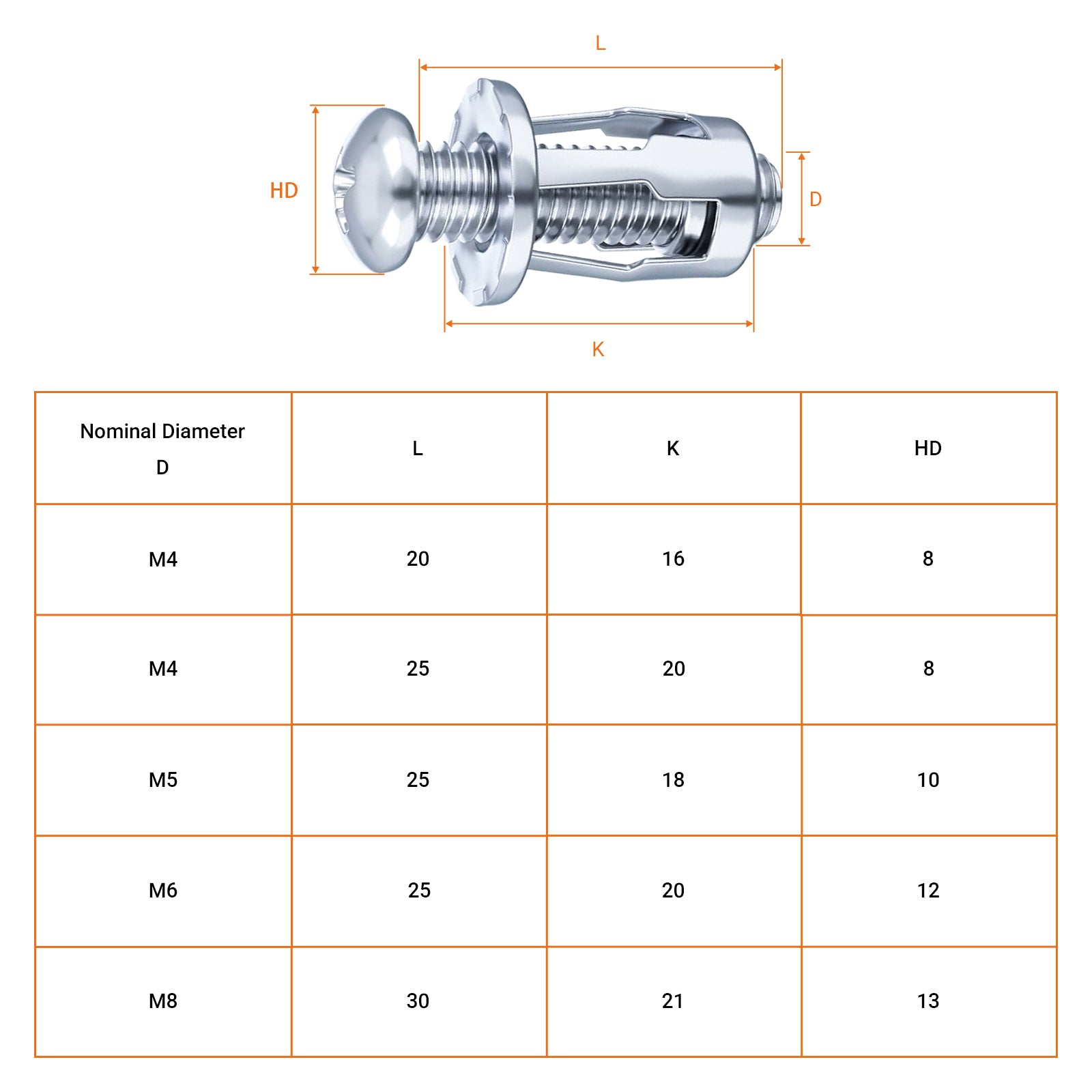

📐 Available Jack Nut Sizes & Specifications

M4 Jack Nut

8mm Hole Size

15mm Length

M5 Jack Nut

10mm Hole Size

18mm Length

M6 Jack Nut

12mm Hole Size

18.5mm Length

M8 Jack Nut

15mm Hole Size

21mm Length

📊 Detailed Jack Nut Technical Specifications

| Thread Size |

Drill Hole Size |

Length |

Thread Pitch |

Grip Range |

| M4 Jack Nut |

8 mm |

15 mm |

0.7 mm |

0.0-5.0 mm |

| M5 Jack Nut |

10 mm |

18 mm |

0.8 mm |

0.0-5.0 mm |

| M6 Jack Nut |

12 mm |

18.5 mm |

1.0 mm |

0.0-5.0 mm |

| M8 Jack Nut |

15 mm |

21 mm |

1.25 mm |

0.0-5.0 mm |

Material: Steel Finish: Bright Zinc Plated (BZP) Type: Blind Threaded Insert Also Called: Spider Nut, Rivnut

✨ Key Features of Blind Jack Nuts

-

One-Side Installation: These blind threaded inserts install completely from the front side - no access needed behind the material!

-

Strong Threaded Anchors: Creates durable, reusable internal threads in materials too thin for tapping.

-

Vibration Resistant: Once installed, jack nuts provide excellent resistance to vibration loosening.

-

Corrosion Protected: Bright zinc plating offers good corrosion resistance for indoor and outdoor applications.

-

Versatile Applications: Work with sheet metal, plastic, wood, fiberglass, and composite materials.

-

Reusable Threads: Unlike some fasteners, these threaded inserts allow repeated screw removal and reinsertion.

🔧 How to Install Spider Jack Nuts

1

Drill Hole

Match size chart

2

Insert Nut

Into pre-drilled hole

3

Tighten Screw

Causes splaying

4

Remove Screw

Threads ready!

🏎️ Common Applications for Jack Nuts

-

Automotive Repair: Adding threads to body panels, fenders, and interior components

-

RV & Trailer Maintenance: Securing panels and fixtures to thin metal frames

-

Sheet Metal Fabrication: Creating strong threads in thin gauge metal

-

Plastic & Composite Work: Adding durable threads to brittle materials

-

Furniture Assembly: Reinforcing joints in hollow-core materials

-

DIY Home Projects: Mounting hardware to hollow doors, drywall, or thin panels

❓ Frequently Asked Questions (FAQ) About Jack Nuts

Q: What exactly is a jack nut and how does it work?

A: A jack nut (also called spider nut or rivnut) is a blind threaded insert that creates strong threads in thin materials. You insert it into a pre-drilled hole, then tighten a screw into it. As you tighten, the backside of the nut splays out (like spider legs), gripping the material from behind. Remove the screw, and you have a permanent, reusable threaded hole.

Q: Do I need a special tool to install these threaded inserts?

A: While specialized jack nut tools exist, you can install them with just a matching screw, washer, and standard tools. Insert the nut, place a washer and screw, then tighten until you feel resistance and the nut splays. Professional installation tools make the process faster and more consistent for high-volume work.

Q: What's the difference between jack nuts and regular rivets?

A: Jack nuts create reusable threaded holes, while regular rivets create permanent mechanical fasteners. After installing a jack nut, you can remove and reinsert screws multiple times. Rivets are single-use and don't provide threads. Jack nuts are ideal when you need removable fasteners in thin materials.

Q: What materials are these jack nuts suitable for?

A: These steel jack nuts work well with sheet metal (steel, aluminum), plastics, wood, fiberglass, and composites. They're perfect for brittle or thin materials where tapping threads would be difficult or impossible. The grip range of 0.0-5.0mm accommodates various material thicknesses.

Q: Can I remove and reuse a jack nut once installed?

A: Jack nuts are designed as permanent installations. Once the back has splayed out, they cannot be easily removed without damaging the material or the nut itself. However, the threaded hole they create is reusable - you can remove and reinsert screws into the installed nut countless times.

Q: Are these the same as "rivnuts" or "spider nuts"?

A: Yes! Jack nuts go by many names including rivnuts (rivet nuts), spider nuts (due to the splayed "legs"), pop nuts, and blind threaded inserts. They all refer to the same type of fastener that provides threaded holes in materials where only one side is accessible.