1. Product core introduction

HomeDIYer brand M1.6 - M5 set screws full thread hex head metric bolts made of 304 stainless steel. Designed for a variety of delicate and small applications, they provide a reliable and long-lasting fastening solution. The full thread design combined with the corrosion resistance of 304 stainless steel ensures reliability and longevity in a wide range of projects. DIY enthusiasts and professionals alike can rely on this product to meet your delicate fastening needs with precision and quality.

2. The main characteristics of the product

High-quality 304 stainless steel material: 304 stainless steel, with excellent corrosion resistance, in the humid, acid and alkali environment can maintain stable performance, and effectively prevent rust, suitable for precision instruments, electronic equipment, medical equipment, etc., which require high rust prevention, which can ensure the long-term reliability of the connection parts, reduce the failure and maintenance costs caused by rust, extend the service life of the product, and ensure the normal operation and performance of the equipment. Stable performance.

Advantage of all-thread design: The all-thread structure of the screw enables the bolt to evenly distribute the fastening force between the connected parts of different thicknesses, providing a more stable and reliable connection, especially suitable for the connection of thin plates or small parts, effectively preventing loosening and enhancing the stability of the overall structure, and giving full play to its advantages on occasions with extremely high requirements for the precision and stability of the connection, such as the assembly of precision machinery and micro-electronic products, ensuring that the equipment or products are connected. Its advantages to ensure the normal work and performance of equipment or products.

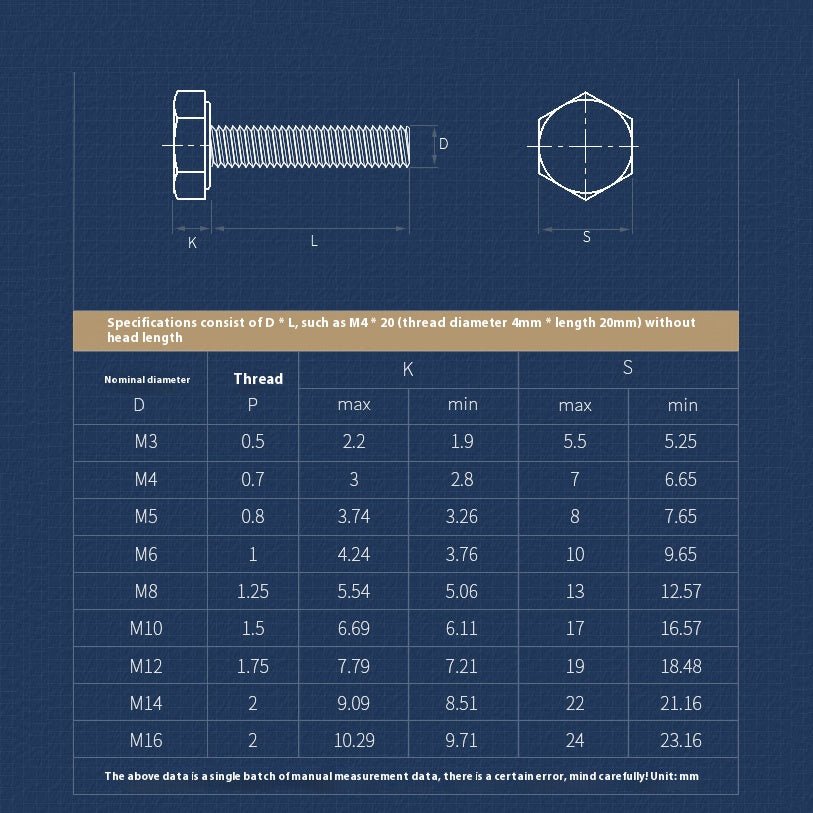

Precise size specification: Provide M1.6 to M5 multiple fine specification options to meet the precise matching needs of various types of small, precision equipment and parts, whether it is the internal structure of small electronic products, precision instruments, parts fixed, or crafts, models, assembly, you can find the right specification, convenient for users to choose according to the actual needs of the realization of accurate and tight connection, improve the installation efficiency and quality of connection, to ensure that the equipment or product normal work and performance. connection quality, ensuring the precision and stability of the equipment or products.

Hexagonal head for easy operation: the head adopts hexagonal design, which is convenient for tightening operation with small wrenches or socket tools, with small operation space requirement, it can be easily operated in narrow and complicated environment, and even in limited space, it can accurately apply tightening torque to ensure that the bolts can reach the required degree of tightening, reduce the difficulty of installation, and improve the work efficiency, which is particularly suitable for the installation scenarios of small equipments and precision components. It is particularly suitable for small equipment and precision parts installation scenarios, and meets the requirements for ease of operation and precision.

3. Product use scene

Electronic equipment and precision instruments: In the internal structure assembly of mobile phones, tablet PCs, laptops, cameras, watches and other electronic equipment, they are used to fix tiny parts, such as motherboards, chips, batteries, cameras, etc. Their high-precision dimensional specifications and stable fastening performance can ensure the normal operation and stable performance of the electronic equipment, and prevent equipment failures due to loosening of the bolts. At the same time, in the manufacture and maintenance of microscopes, telescopes, measuring instruments and other precision instruments, it can also meet the demanding requirements for the precision and stability of parts and components connection to ensure the accuracy and reliability of the instrument, providing strong support for scientific research, medical, industrial testing and other fields.

Small machinery and model making: It is suitable for the manufacture and assembly of small engines (such as model aircraft engines, micro-motors, etc.), power tools (such as micro-drills, screwdrivers, etc.), toy models (such as model cars, model planes, model robots, etc.), and its all-thread design and stainless steel material can ensure the stability and reliability of these small machines in the process of operation and prevent the loosening of bolts due to vibration, impact, etc., and protect the equipment. The all-thread design and stainless steel material can ensure the stability and reliability of these small machines during operation, prevent the loosening of bolts caused by vibration, shock and other factors, and guarantee the normal operation and service life of the equipment. In model making, it is convenient for hobbyists to accurately assemble the models, showing exquisite details and structures, enhancing the quality and ornamental of the models.

Medical devices and jewellery: In the field of medical devices, such as blood glucose meters, blood pressure monitors, small surgical instruments, etc., its stainless steel material hygiene and corrosion resistance and reliable fastening performance can ensure the safety and stability of medical devices, to meet the strict requirements of the medical industry on product quality and reliability. In the production of jewellery, used to fix gems, chains, accessories, etc., not only to ensure the firmness of the connection, but also to show the delicacy and beauty of the ornaments, adding a sense of quality and durability to the jewellery.

4. Product use instructions

Installation steps:

Carefully pass the screw of the bolt through the mounting holes of the connected parts, make sure that the hexagonal surface of the head of the bolt fits closely with the surface of the parts and is flat and without distortion, and add washers to adjust the clearance or increase the friction if necessary.

Use suitable small tools (such as precision wrenches, socket spanners) in the screw screw matching nut, according to the specified tightening torque gradually and uniformly tighten the nut, to avoid unilateral uneven force, for more than one bolt connection, should be tightened in diagonal or cross order, to ensure that the connection is uniform and tight.

In the process of tightening, the connection of the connected parts should be closely observed, if there is any gap or unevenness, the position of the bolt can be adjusted appropriately or a washer can be added to make corrections, to ensure that the connection is tightly fitted without loosening or displacement, to ensure that the precision and stability of the connection.

Precautions for use:

In the process of use, regularly check the status of the bolt connection to see if there are signs of loosening, deformation, corrosion, especially after the equipment is subjected to vibration, temperature changes or long-term use, such as loosening should be promptly re-tightened in accordance with the specified torque, and corrosion damage is found in a timely manner to replace, to ensure that the connection is safe and reliable.

Avoid bolts to withstand excessive external impact or overload, to prevent fracture or damage to the connected parts, in the design and use of the full consideration of the bolt bearing capacity, a reasonable choice of specifications and connection to ensure that the use of the normal operating range.

If it is necessary to dismantle the bolts, use suitable tools to loosen the nuts gradually in the reverse order of installation, avoid forcible dismantling to cause damage to the threads or deformation of the parts, and keep the bolts and accessories properly after dismantling for subsequent use or inspection and maintenance to ensure the performance and accuracy of the next time they are used.