1. Product core introduction

The HomeDIYer brand of M6 - M10 set screws full thread hexagon head metric bolts are crafted from 304 stainless steel. Designed to provide you with a reliable and durable fastening solution, with its full-threaded design and 304 stainless steel properties, it offers excellent strength and corrosion resistance, and is widely used in a variety of scenarios for DIY enthusiasts and professionals alike, who can rely on this product to ensure a solid connection.

2. The main characteristics of the product

High-quality 304 stainless steel material: 304 stainless steel is selected, which has good corrosion resistance, can maintain stable performance in humid, acid and alkali and other harsh environments, and is not easy to rust, which effectively extends the service life, and is suitable for outdoor facilities, kitchen equipment, bathroom fixtures and other occasions with high requirements for rust prevention, ensuring that the connection part is reliable for a long time, reducing maintenance costs and connection failure caused by rust.

Advantage of full-threaded design: the screw part adopts full-threaded structure, compared with partially threaded bolts, the full thread can provide a more uniform distribution of fastening force between the connected parts of different thicknesses, enhancing the stability and reliability of the connection. Whether connecting thin plates or fixing parts with certain thickness requirements, it can fit tightly and effectively prevent loosening, ensuring the safety and solidity of the overall structure, suitable for all kinds of precision equipment and scenarios with high fastening requirements.

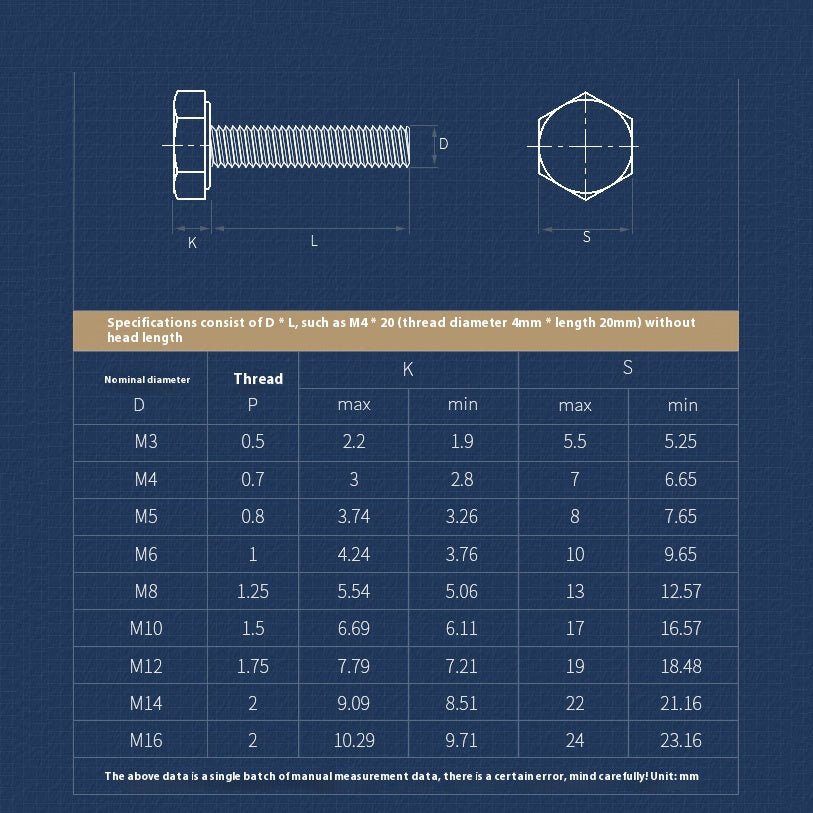

Precise size: Provide M6 to M10 multiple sizes to meet the needs of different sizes of connections, to ensure precise matching with various nuts, studs and connected parts, whether for small electronic products, household goods or medium-sized machinery and equipment, you can find the appropriate specifications, so that users can easily choose according to the actual needs of the improvement of the installation efficiency and quality of the connection, and to achieve accurate and reliable fastening effect. .

Hexagonal head for easy operation: the head adopts hexagonal design, which makes it easy to use tools such as spanners or sockets to carry out tightening operations, and it can provide a larger tightening torque during operation to ensure that the bolts can reach the required degree of tightening in the installation process. Moreover, the shape of the hexagonal head makes it possible to operate it easily in a narrow space or at multiple angles, which improves the convenience and flexibility of the installation, and reduces the difficulty of the installation and the intensity of the work, and is suitable for various complex installation environments.

3. Product use scene

Electronic equipment and electrical maintenance: in all kinds of electronic equipment (such as computers, TVs, stereos, etc.) and household appliances (such as refrigerators, washing machines, microwave ovens, etc.) in the assembly and maintenance, used to fix the internal components and shell, its full-threaded design and precise size specifications to meet the electronic equipment on the parts connected to the precision and stability requirements, to prevent equipment failure due to bolt loosening, and at the same time 304 At the same time, the corrosion resistance of 304 stainless steel can also ensure the reliability and durability of the bolted connection in the complex use of the environment (such as high humidity in the kitchen, electromagnetic interference environment, etc.), to extend the service life of the equipment and reduce the frequency and cost of maintenance.

Furniture and home decoration: Widely used in the manufacture and assembly of furniture, such as tables and chairs, cabinets, bookshelves, etc. Its stainless steel material is beautiful and rust-resistant, and the fastening of hexagonal head bolts is convenient and fast, which ensures the stability and safety of the furniture structure and at the same time meets the requirements of modern homes in terms of aesthetics and quality, and provides users with comfortable and durable furniture products. In addition, in some home decoration projects, such as the installation of lamps and lanterns, pendants, curtain rods, etc., can also play its precise fastening and rust prevention advantages, adding a delicate and reliable home environment.

Small mechanical equipment and tools: in the manufacture and maintenance of small mechanical equipment (such as small engines, power tools, hand tools, etc.), used for the connection of key components, to ensure the stability and reliability of the equipment in the process of operation, to prevent equipment failures due to loosening of the bolts, to meet the requirements of precision equipment on the fastening of parts of the high-precision and stability requirements, to ensure that the equipment works properly and performance, while its 304 At the same time, its 304 stainless steel material can also be adapted to some of the working conditions that may come into contact with liquids or humid environments, improving the overall durability and adaptability of the equipment.

4. Product use instructions

Preparation before installation:

Check the appearance of the bolt for cracks, deformation, thread damage and other defects to ensure that the product quality is intact. At the same time, check whether the supporting nuts, washers and other accessories are complete and appropriate specifications, if any problems with timely replacement, so as not to affect the installation effect.

According to the material, thickness and connection requirements of the connected parts, select the appropriate specifications of the bolt, and determine the corresponding tightening torque, general product manuals or relevant standards will provide reference values, be sure to strictly follow, to avoid improper tightening torque caused by connection problems.

Use cleaning cloth or appropriate solvent to clean the threaded holes of the connected parts and the threaded part of the bolts, remove oil, rust, dust and other impurities to ensure good engagement of the threads and enhance the reliability of the connection and fastening performance.

Installation steps:

Pass the screw of the bolt through the mounting hole of the connected part, make sure that the hexagonal surface of the head of the bolt fits closely with the surface of the part and is flat without skewing, add washers to adjust the gap or increase the friction if necessary.

Screw in the matching nut on the screw, use the appropriate tools (such as spanners, torque wrenches) according to the specified tightening torque to gradually tighten the nut, uniform application of force, to avoid unilateral uneven force, for a number of bolts connected, should be tightened according to the order of the diagonal or cross to ensure that the connection is uniformly tight.

In the process of tightening, pay attention to observe the connection of the connected parts, if there is a gap or uneven phenomenon, you can adjust the position of the bolt or add a washer to correct, to ensure that the connection is tightly fitted, no loosening or displacement.

Precautions for use:

In the process of use, regularly check the bolt connection status, to see whether there are signs of loosening, deformation, corrosion, especially after the equipment is subjected to vibration, temperature changes or long-term use, such as loosening should be promptly re-tightened according to the specified torque, and corrosion damage is found in a timely manner to replace, to ensure that the connection is safe and reliable.

Avoid bolts to withstand excessive external impact or overload, to prevent fracture or damage to the connected parts, in the design and use of the full consideration of the bolt bearing capacity, a reasonable choice of specifications and connection to ensure that the use of the normal operating range.

If it is necessary to dismantle the bolts, use suitable tools to loosen the nuts step by step in the reverse order of installation, avoid forcible dismantling resulting in thread damage or deformation of the parts, and after dismantling, keep the bolts and accessories in a proper way for subsequent use or inspection and maintenance.