1. Product core introduction

HomeDIYer introduces the NXBLE series of circuit breakers, covering a wide range of current sizes such as 6A, 10A, 20A, 25A, 32A, 40A, 50A and 63A, which are designed to provide reliable protection for all types of electrical circuits. Whether for domestic, commercial or industrial applications, these circuit breakers ensure the safe and stable operation of your electrical system by effectively preventing overcurrent and short-circuit conditions, and are a key component in safeguarding electrical equipment and personnel.

2. The main characteristics of the product

Multiple Current Ratings: Providing a wide range of current ratings from 6A to 63A, the circuit breaker can be precisely matched to the load requirements of different electrical equipment and circuits. Whether it is low-power lighting fixtures and small electrical appliances, or high-power industrial equipment and large air-conditioning units, NXBLE circuit breakers can be found in suitable specifications to ensure stable operation of circuits within the range of normal working current, avoid safety accidents caused by overloads or short-circuits, optimize the protection configuration of the electrical system, and improve overall safety and reliability.

Efficient overcurrent protection: The built-in sensitive current sensing device can monitor the current level in the circuit in real time. Once the detected current exceeds the preset rated value, the circuit breaker will quickly and automatically cut off the circuit, with extremely short action time, effectively preventing overheating of wires, damage to the insulation layer, and overcurrent burnt out of electrical equipment, etc. It provides timely and reliable overcurrent protection for the electrical system, and reduces economic losses and safety risks caused by overcurrent faults.

Reliable short-circuit protection: with powerful short-circuit protection function, when a short-circuit fault occurs in the circuit, the huge current generated instantly will be quickly detected by the circuit breaker and immediately trigger the tripping mechanism to cut off the power supply in a very short period of time, stop the impact of short-circuit current on the whole electrical system, protect the lines, equipment and other related electrical components from the damage of short-circuit current, ensure the safety of personnel and equipment, and reduce the risk of serious accidents such as fires caused by short-circuit. Ensure the safety of personnel and equipment, and reduce the possibility of fire and other serious accidents caused by short-circuit.

Durable material and structure: The shell is made of high quality flame retardant and insulating material with good heat resistance, corrosion resistance and mechanical strength, which can be used for a long period of time in harsh environmental conditions without being easily damaged. The internal contacts and mechanical structure are carefully designed and optimised, and wear-resistant and oxidation-resistant metal materials are used to ensure that the circuit breaker has good contact, reliable action and long mechanical life during frequent opening and closing operations, which reduces the maintenance cost and replacement frequency, and provides a solid guarantee of long-term stable electrical protection.

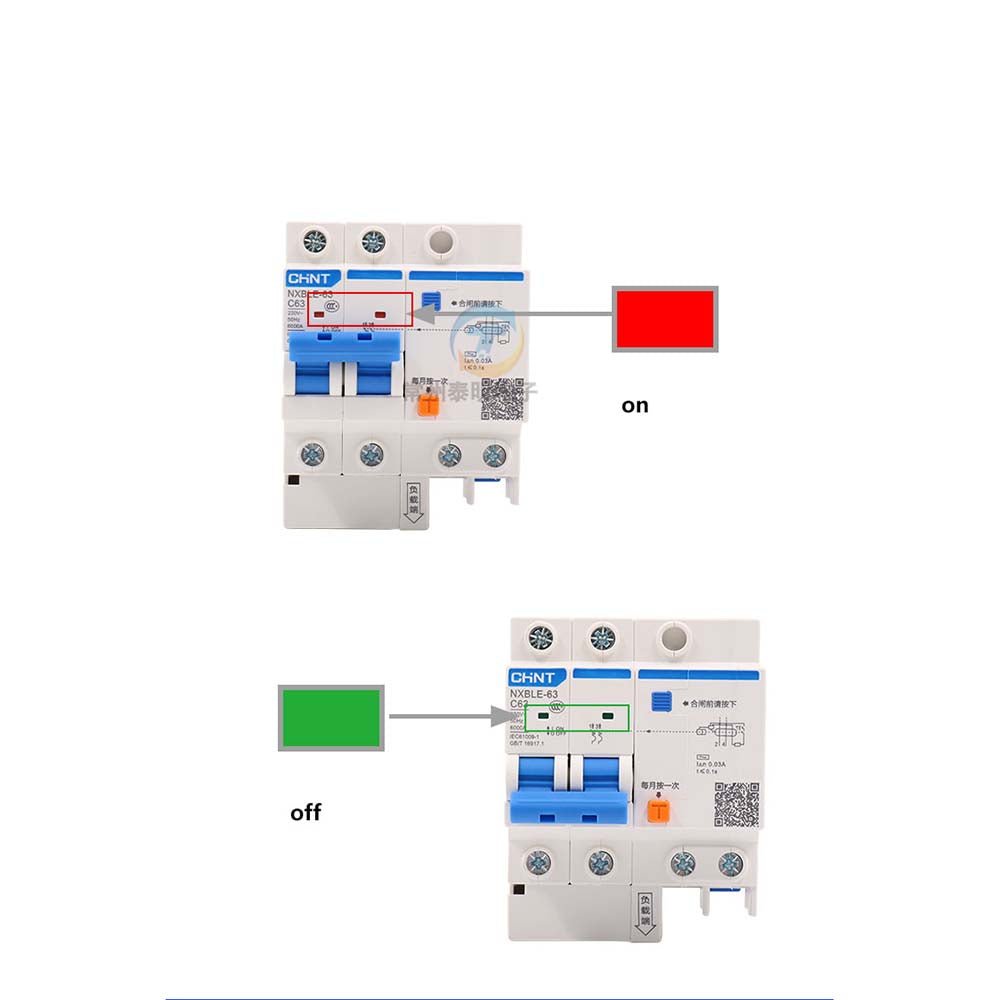

Convenient installation and operation: compact design and small size make it easy to be installed and laid out in distribution boxes, distribution cabinets and other electrical equipment, saving space and improving the integration of the electrical system. At the same time, the operation is simple and convenient, equipped with clear and definite operation handle and indication signs, users can easily carry out closing and breaking operations, and can intuitively understand the working status of the circuit breaker (closing, breaking, or fault tripping), without the need for complex professional skills and tools, lowering the threshold of use and operating difficulty, and facilitating the daily installation, maintenance and use of the user.

3. Product use scene

Family electrical system: In a family house, it can be used for lighting circuits, socket circuits, kitchen appliance circuits, bathroom appliance circuits in each room, as well as special circuits for high-power appliances such as air-conditioners, refrigerators, washing machines, and so on. Different rooms and electrical appliances select NXBLE circuit breakers with appropriate current specifications according to their power sizes, such as 6A - 10A for lighting and small electrical sockets, 16A - 25A for kitchen electrical appliances and bathroom electric water heaters, and 32A - 63A for air conditioners and electric heaters. When there is an overload or short circuit in the family circuit, the circuit breaker can quickly cut off the faulty circuit, protect the safety of family electricity, avoid the fire and other dangers caused by electrical failure, and ensure the safety of family members' lives and property and normal living order.

Application in commercial places: It is suitable for the protection of electrical system in all kinds of commercial places, such as shops, restaurants, offices, hotels and so on. Commercial places usually have a large number of lighting fixtures, office equipment, commercial electrical appliances (such as cash registers, refrigerated display cabinets, electric ovens, etc.) as well as air conditioning and ventilation systems, etc., which have high requirements for the stability and safety of power supply.NXBLE circuit breakers can be reasonably configured in accordance with the power consumption requirements of different areas and equipment to ensure that each branch of the electrical circuit is effectively protected, preventing the normal operation of the entire commercial place from being affected by an electrical fault and reducing the risk of fire caused by family members and normal living order. NXBLE circuit breaker can be reasonably configured according to the power consumption requirements of different areas and equipments to ensure that each circuit branch is effectively protected, preventing the normal operation of the whole commercial place from being affected by an electrical fault, reducing the economic loss and the interruption of commercial activities due to power failure, and providing a reliable electric power guarantee for commercial business activities.

Industrial production environment: In the industrial field, it can be widely used in factory production equipment, production lines, power systems, lighting systems and various industrial control circuits. Industrial equipments often have high power and complex electrical control systems, and need circuit breakers that can withstand high-current impact and frequent operation to protect them.NXBLE circuit breakers with various high-current specifications (e.g. 40A - 63A) can meet the needs of industrial equipments, and their reliable over-current and short-circuit protection performance can effectively prevent equipment damage and production interruption due to electrical faults in the process of industrial production, Its reliable overcurrent and short-circuit protection performance can effectively prevent equipment damage, production interruption, product quality problems and personnel safety accidents caused by electrical faults during industrial production, ensure the continuity, stability and efficiency of industrial production, and reduce the production costs and operational risks of enterprises.

4. Product use instructions

Preparation before installation:

Carefully check the appearance of the circuit breaker to see if there are defects such as breakage, deformation, contact oxidation, shell cracks, etc. If there are any problems, the supplier should be contacted for replacement in time to ensure that the quality of the NXBLE circuit breaker to be used is intact and undamaged.

Determine the required circuit breaker current specification according to the actual application scenario and the design requirements of the electrical system, and prepare suitable installation tools, such as screwdrivers, wrenches, sharp-nosed pliers, wire strippers, etc., to ensure the precision and applicability of the tools, so as to avoid damaging the circuit breakers during the installation process.

Installation and Connection:

Install the NXBLE circuit breaker on the rail of the distribution box or distribution cabinet, ensure that the installation is firm and free from looseness. Correctly connect the power and load wires according to the wiring plan of the electrical system. In general, the power supply line is connected to the input terminal of the circuit breaker (usually labelled ‘LINE’ or ‘IN’), and the load line is connected to the output terminal (usually labelled ‘LOAD’ or ‘OUT"), pay attention to the correctness and firmness of the wiring to avoid wrong wiring or false connection. After the wiring is completed, use a screwdriver to tighten the screws on the terminals to ensure that the wires are in close contact with the terminals, to prevent heat, fire or failure due to poor contact.

Debugging and Testing:

After completing the installation and wiring, close the circuit breaker to check whether it can work properly. Professional electrical test instruments, such as multimeters, can be used to measure the voltage, current and other parameters of the circuit to ensure that the circuit is properly energised and that the circuit breaker can accurately monitor and protect the circuit. At the same time, simulate overcurrent and short-circuit situations to test whether the circuit breaker's protection function is sensitive and reliable.

Precautions for use:

Regularly check and maintain the circuit breaker to see if there is any abnormality in its appearance, such as heat, smoke, odour, discolouration of the shell. At the same time, check the wear of the contacts, if the contacts are found to be severely worn or ablated, the contacts or the whole circuit breaker should be replaced in time to ensure its normal opening and closing performance and protection function. It is generally recommended to carry out comprehensive inspection and maintenance every certain period of time (e.g. half a year or one year), and the specific time interval can be determined according to the actual use environment and frequency.

When operating the circuit breaker, follow the correct operation method to avoid damage to the circuit breaker caused by barbaric operation. Before closing the circuit breaker, ensure that there is no short-circuit or earth fault in the load circuit; after opening the circuit breaker, wait for a certain period of time (usually a few minutes) before closing the circuit breaker, so as to avoid any danger caused by the residual charge present in the circuit. In addition, do not force the circuit breaker to close when it is in a faulty tripping state; remove the cause of the fault first and ensure that the circuit is restored to normal before carrying out the closing operation.

Avoid the circuit breaker to be affected by humidity, high temperature, corrosive gases, strong vibration and other harsh environments, if the installation environment is poor, corresponding protective measures should be taken, such as the addition of protective cover, ventilation device, shock pads, etc., in order to prolong the service life of the circuit breaker and ensure the stability of its performance. At the same time, attention should be paid to avoid the accumulation of debris around the circuit breaker, to keep its surrounding environment clean and well-ventilated, to facilitate heat dissipation and operation and maintenance.