🔍 Discover Our U-Shape Frameless Glass Seal

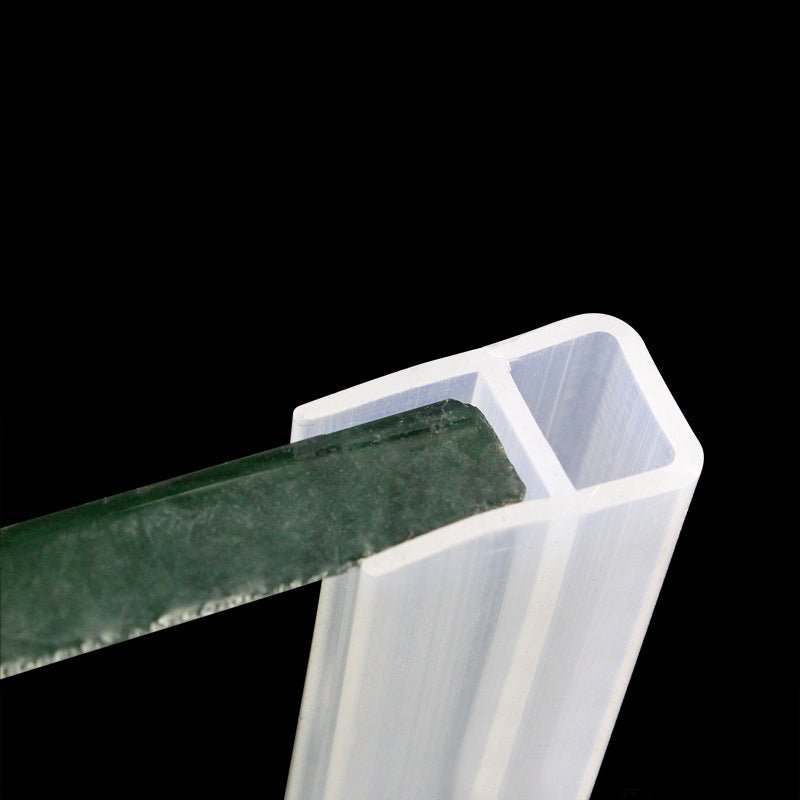

Upgrade your frameless glass projects with the premium U-Shape Frameless Glass Seal from HomeDIYer! This innovative seal ensures a secure, watertight fit for various applications, enhancing both functionality and aesthetics. Made from durable silicone rubber, it offers excellent flexibility and resistance to harsh elements. Perfect for DIY enthusiasts looking for a reliable solution. 🌟

📊 U-Shape Frameless Glass Seal Specifications

| Feature |

Details |

| Product Type |

U-Shape Frameless Glass Seal |

| Material |

High-Quality Silicone Rubber |

| Available Sizes |

10/12u, 6/8U (compatible with various glass thicknesses) |

| Length |

1 Meter |

| Key Applications |

Frameless Glass Doors, Shower Enclosures, Balcony Railings |

| Installation Types |

Bayonet, Adhesive, or Embedded Styles |

✨ Key Features of Our Frameless Glass Seal

- 🔒 Tight Fit Sealing: U-shape design fills gaps effectively, preventing water, dust, and air leakage for long-lasting protection.

- 🔄 Excellent Flexibility: Adapts to thermal expansion and minor displacements without cracking, ensuring consistent performance.

- 🛡️ Durable Material Selection: Weather-resistant silicone rubber withstands UV, temperature extremes, and moisture, reducing maintenance needs.

- 🔧 Easy Installation: DIY-friendly with simple methods like snap-on or adhesive application—no professional skills required!

🏡 U-Shape Frameless Glass Seal Use Scenes

Ideal for balcony frameless glass balustrade systems, this seal enhances stability and blocks rain, dust, and debris. It creates a secure, transparent space for outdoor leisure, improving home safety and comfort. Also great for shower enclosures and other frameless glazing projects! 💧

📝 U-Shape Frameless Glass Seal Usage Instructions

🔧 Pre-Installation Preparation

Inspect the seal for defects, ensure compatibility with your glass, and clean surfaces thoroughly. Gather tools like scissors or a glue gun for a smooth setup.

🛠️ Installation Steps

For adhesive types, peel and apply along the glass edge; for snap-on styles, align and press into place. Work slowly to avoid bubbles or gaps, and check for a firm fit.

⚠️ Usage Precautions

Avoid harsh chemicals and physical impacts. Regularly inspect for wear, especially after extreme weather, and replace if damaged to maintain optimal sealing.

❓ FAQ About U-Shape Frameless Glass Seal

How do I install the U-Shape Frameless Glass Seal? 🛠️

Installation is simple! For adhesive seals, clean the glass edge, peel the backing, and press firmly along the surface. For snap-on types, align the seal with the groove and push it into place. Always refer to the product manual for detailed steps tailored to your project.

What materials is this frameless glass seal made of? 🌿

It's crafted from high-quality silicone rubber, offering excellent durability, flexibility, and resistance to UV rays, temperature changes, and moisture. This ensures long-term performance without cracking or discoloration.

Can I use this seal for outdoor frameless glass applications? 🏞️

Absolutely! Our U-Shape Frameless Glass Seal is designed for both indoor and outdoor use, including balcony railings and glass doors. Its weather-resistant properties protect against elements like rain and dust.

How do I maintain and clean the seal? 🧽

Use a soft cloth with mild soap and water for cleaning. Avoid abrasive cleaners or solvents to prevent damage. Regularly check for signs of wear and replace if needed to ensure continued sealing efficiency.

What sizes are available for this frameless glass seal? 📏

This product comes in 10/12u and 6/8U sizes, with a standard length of 1 meter. It's compatible with various frameless glass thicknesses—check our specifications table for more details.