The Ultimate Guide to Heat Shrink Tubing: Uses, Materials, Installation & Best Practices

Table of Contents

- What is Heat Shrink Tubing? (Heat Shrink Sleeves & Wire Insulation)

- The Science Behind Heat Shrink Tubing: Shrink Ratios & Polymer Memory

- Materials & Types of Heat Shrink Tubing (Polyolefin, PVC, Adhesive-Lined)

- Top Uses & Applications for Heat Shrink Tubing

- How to Choose the Right Heat Shrink Tubing (Size, Ratio, Material)

- Step-by-Step Installation Guide for Heat Shrink Tubing

- Advanced Techniques: Dual-Wall, Solder-Joint, and Spiral Heat Shrink

- Heat Shrink Tubing in Automotive & Marine Wiring

- Industrial & Aerospace Uses of Heat Shrink Tubing

- Troubleshooting Common Heat Shrink Tubing Issues

- Safety, Certifications & Long-Term Reliability

- Frequently Asked Questions (Heat Shrink Tubing FAQ)

- Where to Buy & Recommended Kits (Heat Shrink Kit Recommendations)

- Conclusion: When to Use Heat Shrink Tubing vs Alternatives

What is Heat Shrink Tubing? (Heat Shrink Sleeves & Wire Insulation)

Also referred to as heat shrink tubing, heat shrink sleeves, or simply shrink tubing, this product is one of the most commonly used insulating accessories in electrical work.

In essence, heat shrink tubing is a tubular polymer material engineered to shrink when exposed to heat. It starts with a diameter larger than the object it will cover, is slid into place, and then heated so the tube reduces in diameter and tightly conforms to the underlying shape. This results in:

- Electrical insulation — preventing shorts and leakage

- Mechanical protection — guarding against abrasion and wear

- Environmental sealing — keeping out moisture, salt, and contaminants

- Strain relief — distributing stress at connection points

- Identification — color-coding wires and harnesses for organization

Although its concept is straightforward, the variations in material, shrink ratio, wall thickness, and special features (like adhesive lining or flame retardance) make selecting the right tubing an engineering decision for every serious project.

Why use Heat Shrink Tubing?

Compared with alternatives like electrical tape, liquid electrical tape, or braided sleeving, heat shrink tubing often wins on durability, neatness, and sealing capability. It offers a permanent solution that resists vibration, solvents, and UV when chosen appropriately.

The Science Behind Heat Shrink Tubing: Shrink Ratios & Polymer Memory

Understanding the manufacturing and material science helps you predict behavior during installation and over time.

Shrink Ratios

Shrink ratio is one of the first specs to watch. Common ratios include:

- 2:1 — most common, balanced fit for general use

- 3:1 — useful when size differences are larger or connectors are odd-shaped

- 4:1 — for very irregular or bulky joints

Example: A 3:1 tube with a 9mm diameter will shrink down to 3mm. Always measure the largest diameter of the object after connector assembly — that’s the number you need to match against the tubing’s pre-shrink inner diameter.

Polymer Memory & Heat Response

The tubing is extruded and then expanded (stretched) at high temperature, then cooled quickly. This “sets” the expanded shape. When reheated during installation, the polymer relaxes back to the original calibrated diameter. Different polymers and additives determine the temperature thresholds, flame resistance, flexibility, and aging characteristics.

Materials & Types of Heat Shrink Tubing (Polyolefin, PVC, Adhesive-Lined)

Choosing the right material is crucial — a tube used in an engine bay has different needs than one inside a hobby Arduino project. Below is an industry-focused breakdown.

| Material | Properties | Temperature Range | Common Applications |

|---|---|---|---|

| Polyolefin | High electrical insulation, flexible, UV and abrasion resistant, flame-retardant grades available | -55°C to +135°C (typical) | General-purpose wiring, HVAC, consumer electronics |

| PVC | Cheap, durable, chemically resistant; less flexible at low temps | -40°C to +105°C | Automotive harnesses, low-cost applications |

| Fluoropolymer (PTFE, FEP) | Exceptional chemical & heat resistance, slippery surface | -65°C to +260°C | Aerospace, high-temp industrial systems |

| Silicone | Extreme flexibility and high temp resistance | -65°C to +200°C | High-temp lighting, flexible cables |

| Dual-Wall / Adhesive-Lined | Inner hot-melt adhesive flows when heated to create a water-tight seal | -55°C to +110°C | Marine, outdoor, underground, oil-exposed environments |

| Specialty (PVC braided, spiral) | Mechanical protection, expandable, non-shrink variants | Varies | Cable management, abrasion zones |

Tip: For outdoor and saltwater environments, always favor adhesive-lined (dual-wall) polyolefin specially rated for marine use.

Top Uses & Applications for Heat Shrink Tubing

Heat-shrink tubing shines in a wide range of fields. Below, we cover practical use-cases with notes on material and technique.

1. Electrical Wire Insulation & Splice Protection

Cover soldered splices or butt connectors with appropriate shrink to prevent shorts and strengthen the joint. Use adhesive-lined tubing for waterproofing splices in outdoor or vehicle applications.

2. Strain Relief & Connector Reinforcement

Slide tubing over cable entries to reduce flex fatigue. Thin-wall polyolefin is often adequate; for heavy-duty applications, choose thick-wall or braided options.

3. Environmental & Chemical Protection

Adhesive-lined (dual-wall) heat shrink tubing forms a hermetic seal, protecting against moisture, salt spray, and many solvents.

4. Wire and Harness Identification

Color-coded tubing simplifies maintenance and fault-finding. Use printed tubing or colored sleeves to mark phases, voltages, or signal types.

5. Mechanical Abrasion Protection

In harsh environments where wires rub against chassis or metal, thick-wall heat shrink or removable sleeving prevents insulation wear.

6. Sealing Sensor Leads & Coaxial Joints

Shield coax joints and sensor wires with specialized heat shrink; PTFE or high-temp polyolefin may be necessary when temperatures are elevated.

7. Repairing Damaged Insulation

Instead of replacing entire cables, spot-repair damaged sheath sections with correctly sized shrink to restore insulation and mechanical protection.

8. Manufacturing & Assembly: Consistency & Speed

In mass production, heat shrink is often applied by infrared or hot-air tunnels for consistent, fast results that meet quality requirements.

9. Hobby Electronics & Prototyping

Arduino projects, home audio, and hobby RC gear benefit from tidy, insulated connections. Clear or colored tubing adds a professional look.

10. High-Temperature & Specialized Industrial Use

PTFE and fiberglass-based shrink wrap provide insulation where ordinary polymers would fail — e.g., near furnaces, turbines, or lighting fixtures.

How to Choose the Right Heat Shrink Tubing (Size, Ratio, Material)

How to Choose the Right Heat Shrink Tubing (Size, Ratio, Material)

Choosing the wrong tubing leads to installation headaches or premature failure. Use this checklist:

- Measure the largest assembled diameter — connectors, solder beads, and shrink tubing over solder must clear that size before shrinking.

- Select the correct shrink ratio — 2:1 for standard jobs, 3:1 when connector shapes vary, 4:1 for very irregular shapes.

- Match material to environment — polyolefin for general use; adhesive-lined for moisture protection; PTFE for extreme heat/chemicals.

- Pick wall thickness — thin for signal wires, thick for abrasion-prone cables.

- Check temperature rating — both operating range and application temperature tolerance.

- Certifications — UL ratings, MIL spec, RoHS, or automotive OEM specs may be required.

| Project Type | Suggested Material | Shrink Ratio |

|---|---|---|

| Home electronics | Polyolefin, thin-wall | 2:1 |

| Automotive wiring | Polyolefin or PVC, thick-wall | 2:1 or 3:1 |

| Marine/outdoor | Dual-wall adhesive-lined polyolefin | 2:1 |

| High-temp industrial | PTFE / Silicone | Specialty ratios |

| Soldered waterproof joints | Adhesive-lined (dual-wall) | 2:1 or 3:1 |

Step-by-Step Installation Guide: How to Properly Apply Heat Shrink Tubing

Follow these steps for reliable results:

Preparation

- Measure the assembled diameter (including connectors or solder beads).

- Cut the tubing, leaving 2–5 mm overlap on each side for best sealing.

- Ensure surfaces are clean — remove oil, corrosion, or loose insulation.

- Keep a selection of sizes on hand; a multi-size kit saves time.

Application

- Slide the tubing onto the wire before making connections when possible.

- Complete soldering or crimping.

- Position the tubing centered over the splice or connector.

- Use a heat gun set to the recommended temperature — typically 120°C–200°C depending on the material. Maintain movement and avoid holding the gun too close.

- Watch the tubing shrink evenly; stop heating once it conforms smoothly.

- If using adhesive-lined tubing, allow a few seconds for the adhesive to flow and wet the substrate; then cool to set.

Pro Tip: Tools & Techniques

Use a proper heat gun with an adjustable temperature, not a lighter or open flame. For delicate electronics, use a hot-air rework station with controlled airflow. Infrared ovens and convection tunnels are used in production for repeatable results.

Advanced Techniques: Dual-Wall, Solder-Joint Heat Shrink, and Spiral Heat Shrink

Once comfortable with basics, these advanced options expand capabilities:

Dual-Wall (Adhesive-Lined) Heat Shrink Tubing

Combines a structural outer wall with a hot-melt adhesive inner layer. When heated, the adhesive flows and creates a watertight seal — ideal for marine, underground, and outdoor splices.

Solder-Joint Heat Shrink Tubing

Contains a pre-formed solder ring inside the tube. When heated, the solder reflows and the tube shrinks in one step — producing robust, conductive, and sealed splice joints. Great for field repairs where soldering and sealing in one operation saves time.

Spiral & Expandable Heat Shrink

Spiral or expandable non-shrink sleeving is used where repeated access is needed; some hybrid products combine shrink features with wrap-around access for retrofit jobs.

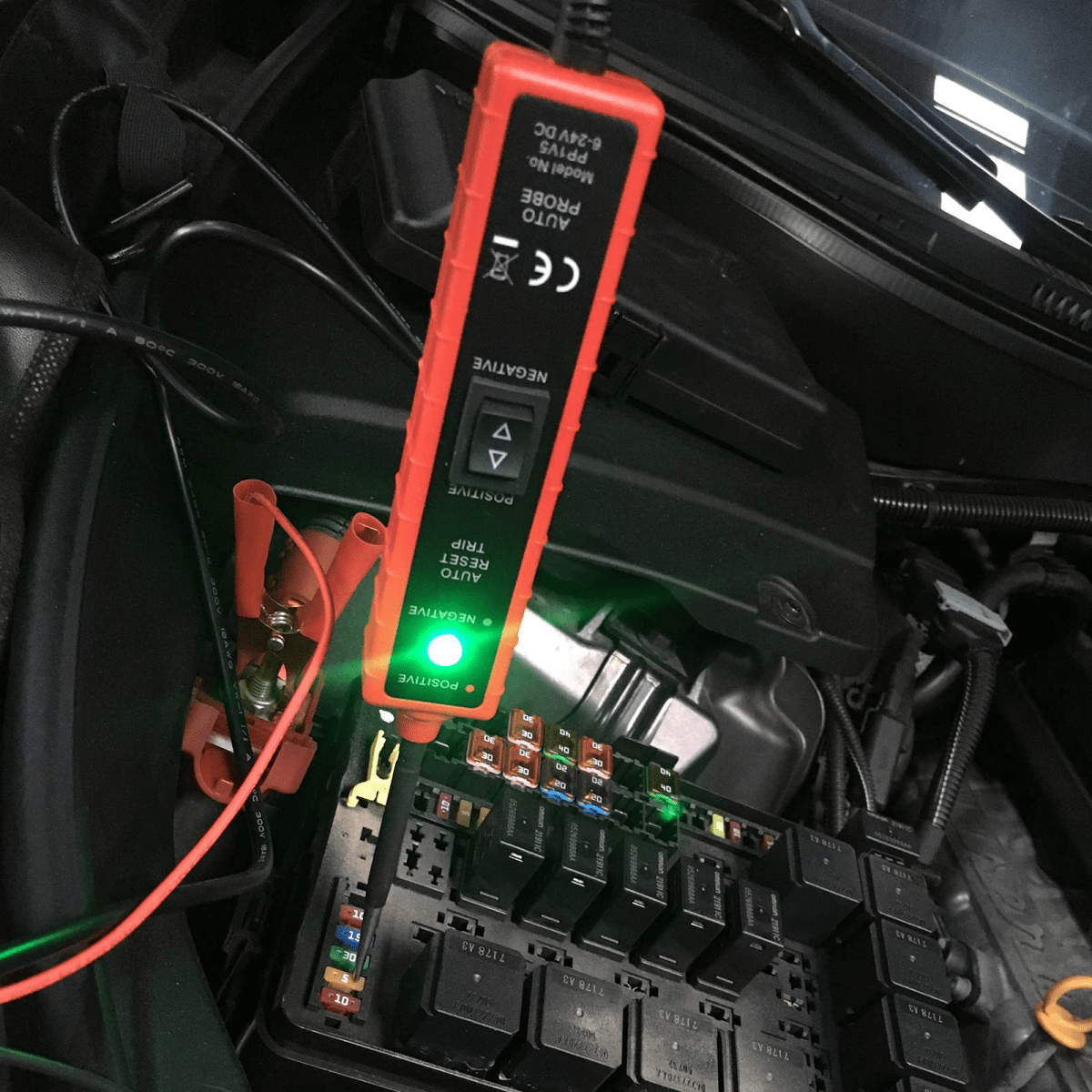

Heat Shrink Tubing in Automotive & Marine Wiring

Engine bays and marine environments pose vibration, oil/grease, salt spray, and temperature cycles. Recommendations:

- Use polyolefin with flame-retardant additives for automotive harnesses.

- Choose adhesive-lined tubing for any exposure to water or salt.

- Use thicker-walled tubing near connectors and grommet pass-throughs.

- Consider high-temp silicone or PTFE near exhausts or engine blocks.

Industrial & Aerospace Uses of Heat Shrink Tubing

Industrial and aerospace applications demand traceability, certification, and extreme environmental performance. MIL-spec heat shrink and high-temp fluoropolymers are common where flame, solvents, or high-vacuum conditions exist. Documentation and lot traceability are often required in procurement.

Troubleshooting Common Heat Shrink Tubing Issues

Problems can usually be traced to wrong material, inadequate heat, or poor preparatory work. Below is a practical troubleshooting table:

| Problem | Likely Cause | Solution |

|---|---|---|

| Uneven shrinkage/wrinkles | Too much heat in one spot or inconsistent movement | Move the heat gun continuously; back off on the temperature; use a lower temperature or increase the distance |

| The tube won't shrink | Insufficient heat or wrong material (high-temp required) | Increase temperature gradually; verify material spec; use proper gun |

| Blisters or burnt surface | Overheating / open flame used | Lower the temperature, keep distance, avoid flame |

| Adhesive didn't flow (dual-wall) | Insufficient application temp or too fast cooling | Apply heat longer and ensure correct temp; allow adhesive to wet surfaces |

| Short lifespan in outdoor use | Non-UV resistant tubing used | Switch to UV-stabilized polyolefin or protective jacket |

Safety, Certifications & Long-Term Reliability of Heat Shrink Tubing

For commercial and safety-critical uses, check the following:

- UL (Underwriters Laboratories) approvals — for electrical safety

- MIL-Spec — for aerospace/defense applications

- RoHS — material compliance for hazardous substances

- Flame-retardant ratings — required for many building and automotive installations

Long-term reliability depends on proper selection and installation: correct material, good surface prep, and controlled heating reduce the chance of premature failure.

Frequently Asked Questions About Heat Shrink Tubing

What's the difference between electrical tape and heat shrink tubing?

Electrical tape is temporary and can loosen over time; heat shrink tubing offers a permanent, sealed solution with better mechanical and environmental protection.

Can I use a lighter to shrink tubing?

Using a lighter is not recommended. It produces uneven heat, can burn the tubing or underlying wire, and risks damage to insulation. Use a controlled heat gun for predictable, safe results.

How should I size heat-shrink tubing for a splice?

Measure the largest assembled diameter and pick tubing with a pre-shrink inner diameter slightly larger. As a rule of thumb, choose tubing that is ~20–30% larger than the pre-shrink target diameter to allow easy installation.

Are there heat-shrink options for waterproofing?

Yes — adhesive-lined (dual-wall) heat shrink tubing melts an inner adhesive layer during heating and creates a watertight seal.

How long will shrink tubing last?

With proper material selection (UV-stable, correct temperature rating) and installation, heat shrink tubing can last the lifetime of the wiring — often decades in benign environments and many years even outdoors when the right grade is chosen.

Can heat-shrink tubing be used on fiber optic cables?

Specialized heat shrink products exist for fiber optic terminations, but be careful: fiber optics is sensitive to bending radii and heat — follow fiber-specific manufacturer guidance.

Where to Buy & Recommended Kits (Heat Shrink Kit Recommendations)

For hobbyists and professionals, a multi-size kit (e.g., a 300–500 piece assortment) covering 1.2mm through 25mm diameters with at least 2:1 and 3:1 ratios covers most needs. For automotive and marine work, include dual-wall adhesive-lined sets and some thick-wall pieces for abrasion zones.

Our recommended starter kit (great for workshops) includes a spread of 2:1 and 3:1 polyolefin tubing, plus several dual-wall pieces for outdoor splices. (328-piece colorful heat shrink tubing set)

Conclusion: When to Use Heat Shrink Tubing vs Alternatives

Heat shrink tubing is the preferred choice when you need a durable, neat, and sealed solution. Use electrical tape for temporary fixes, braided sleeving for abrasion protection where easy access is needed, and heat shrink for permanent insulation and waterproofing. The right combination of material, shrink ratio, and installation technique will deliver long-lasting, professional-grade results.

Whether you're a DIYer fixing a lamp cord, an auto tech rebuilding a harness, or an engineer designing a control cabinet, a good understanding of heat shrink tubing options and installation best practices makes your work safer and more reliable.