Table of Contents

- Why Bolt Size Matters

- Understanding Bolt Anatomy

- Tools You'll Need for Identifying Bolt Size

- Step-by-Step Guide to Measuring Bolt Size

- Common Bolt Size Standards: Metric vs. Imperial

- Using a Bolt Size Finder Tool

- Tips for Identifying Bolt Size Without Tools

- Common Mistakes to Avoid

- Frequently Asked Questions

Why Bolt Size Matters

Using the correct bolt size isn't just about convenience—it's about safety and structural integrity. A bolt that's too small can shear under pressure, while one that's too large might not fit properly or could damage the materials you're fastening. When working on automotive repairs, furniture assembly, or structural projects, precise fastener sizing is critical.

Many DIYers struggle with how to find bolt size when they have a random bolt without packaging or need to replace a missing fastener. This guide will eliminate that frustration by providing multiple methods for bolt identification.

Understanding Bolt Anatomy

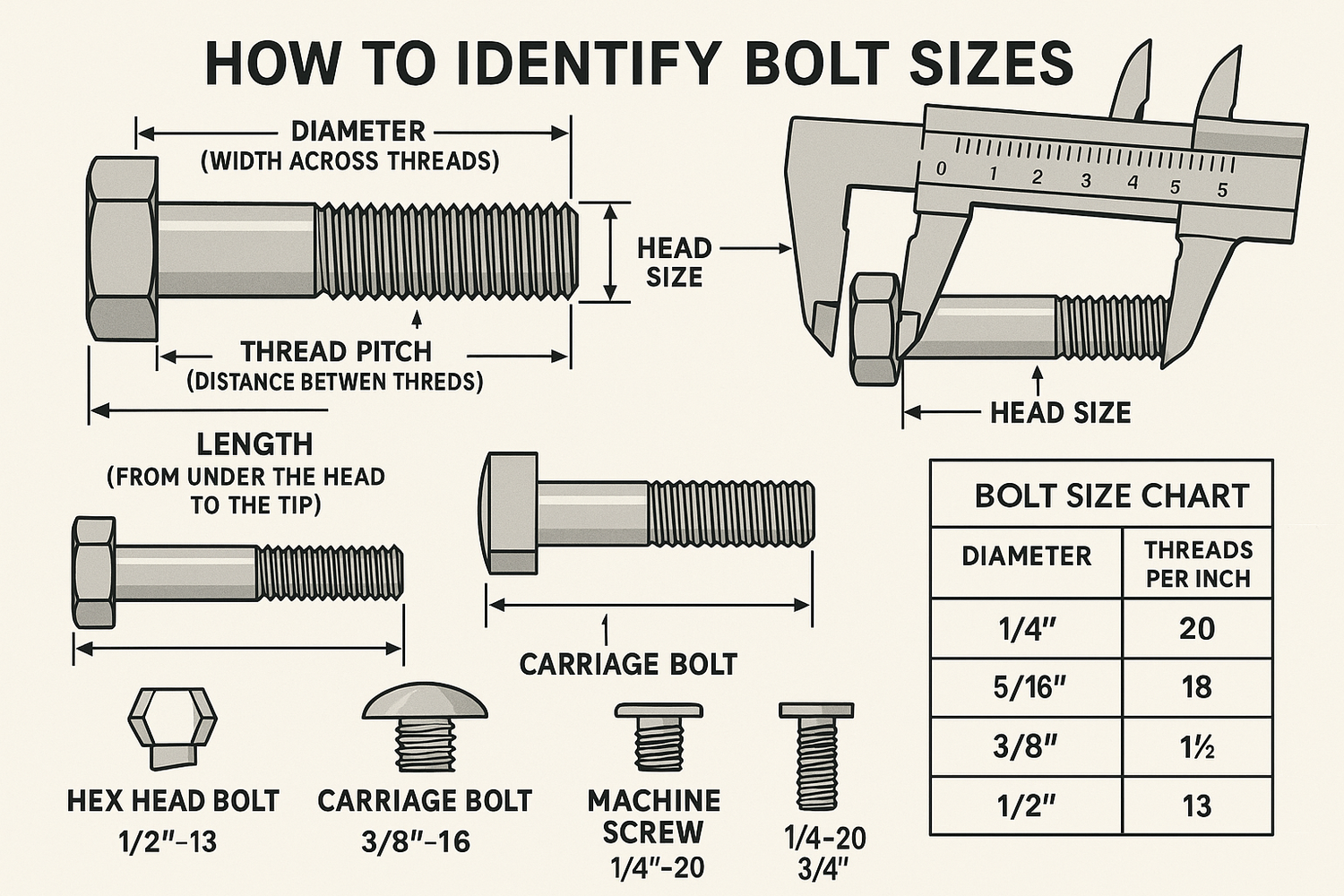

Before we dive into measurement techniques, it's important to understand the key components of a bolt:

- Head: The top part of the bolt that you turn with a tool

- Shank: The smooth portion between the head and threads

- Threads: The spiral ridges that engage with nuts or threaded holes

- Length: The measurement from the bottom of the head to the tip of the bolt

- Diameter: The thickness of the bolt shaft

- Thread Pitch: The distance between adjacent threads

Each of these dimensions matters when selecting replacement bolts or matching nuts to existing bolts.

Tools You'll Need for Identifying Bolt Size

While you can identify basic bolt dimensions with common tools, having specialized equipment makes the process faster and more accurate:

- Caliper: The most precise tool for measuring diameter and length

- Thread Gauge: Specifically designed to measure thread pitch

- Ruler or Tape Measure: For approximate measurements

- Bolt Size Chart: Reference guide for standard sizes

- Bolt Size Finder: A specialized tool that quickly identifies both diameter and thread pitch

For most DIY applications, a combination of calipers and a bolt head size finder will cover your needs. The latter is particularly useful because it eliminates guesswork when dealing with worn or damaged threads.

Step-by-Step Guide to Measuring Bolt Size

Step 1: Determine the Bolt Type

First, identify whether you're dealing with a machine bolt, carriage bolt, lag bolt, or specialty fastener. This will help you understand which measurements are most important.

Step 2: Measure the Diameter

Using calipers or a wrench, measure the outside diameter of the threaded portion. For bolts with threads extending to the head, measure the major diameter (the outermost points of the threads). Place the bolt between the jaws of your caliper and gently close them until they contact the bolt surfaces.

Pro Tip: If you don't have calipers, you can use an open-end wrench to determine bolt size. Find the wrench that fits snugly around the bolt threads—the wrench size typically corresponds to the bolt diameter.

Step 3: Determine the Thread Pitch

Thread pitch refers to the distance between threads. For imperial bolts, this is measured in threads per inch (TPI). For metric bolts, it's the distance in millimeters between adjacent threads.

To measure TPI, count how many thread peaks fit in one inch. For metric pitch, use a thread pitch gauge or measure the distance between several threads and divide by the number of spaces between them.

Step 4: Measure the Length

Bolt length is measured from the underside of the head to the tip. For countersunk bolts, measure the entire length. Use a ruler or caliper for this measurement.

Step 5: Identify the Head Style and Drive Type

Note the head shape (hex, round, flat, etc.) and drive type (Phillips, slotted, Torx, hex socket, etc.). This information is crucial when selecting replacement bolts or when you need to find the bolt size for specific applications.

Common Bolt Size Standards: Metric vs. Imperial

Understanding the difference between metric and imperial (SAE) bolt systems is essential for proper identification:

Imperial (SAE) Bolts

Common sizes include: 1/4", 5/16", 3/8", 7/16", 1/2", 9/16", 5/8", etc. Imperial bolts are identified by their diameter in inches or fractions of an inch, followed by their thread count (e.g., 1/4"-20).

Metric Bolts

Common sizes include: M6, M8, M10, M12, M14, etc. The number after "M" indicates the diameter in millimeters. Metric bolts also include the pitch measurement (e.g., M8-1.25).

When you're trying to how to find bolt thread size, knowing which system you're working with is the first step. Most modern vehicles and equipment use metric fasteners, while older American-made products often use imperial.

Using a Bolt Size Finder Tool

A dedicated bolt size finder tool is the fastest and most accurate way to identify unknown bolts. These tools typically feature multiple holes or gauges corresponding to common bolt sizes.

To use a bolt size finder:

- Start by testing the bolt in the largest hole that it might fit

- Move to progressively smaller holes until you find the one that fits snugly

- Once you've identified the diameter, use the thread pitch section to determine the thread pattern

- Match your findings to the chart provided with the tool

The advantage of using a specialized bolt head size finder tool is that it accounts for thread wear and minor damage that might throw off manual measurements.

Tips for Identifying Bolt Size Without Tools

While specialized tools make identification easier, there are times when you need to know how to find bolt size with limited resources:

- Compare to Known Bolts: If you have a collection of bolts, try matching the unknown bolt to ones you've already identified.

- Use a Nut for Testing: Find a nut that threads smoothly onto the bolt, then identify the nut size.

- Paper and Pencil Method: Roll the bolt on a piece of paper to create an impression, then measure the distance between thread marks.

- Hardware Store Matching: Take the bolt to a hardware store and use their sizing boards or ask for assistance.

These methods work in a pinch but are less reliable than proper measuring tools, especially for critical applications.

Common Mistakes to Avoid

When learning how to find the size of a bolt, avoid these common errors:

- Confusing Diameter and Head Size: The bolt diameter refers to the threaded portion, not the head size.

- Mixing Metric and Imperial: A metric bolt might seem close to an imperial size, but they're not interchangeable.

- Ignoring Thread Pitch: Two bolts with the same diameter but different thread pitches won't work with the same nuts.

- Measuring Worn Threads: Damaged or worn threads can give inaccurate measurements.

- Forgetting About Length: A bolt that's too long or too short may not work properly in your application.

Frequently Asked Questions

How can I tell if a bolt is metric or imperial?

Look at the markings on the head—metric bolts often have strength class numbers (like 8.8 or 10.9), while imperial bolts may have radial lines or manufacturer logos. You can also measure the diameter—if it's a round number in millimeters, it's likely metric; if it's a fraction of an inch, it's imperial.

What's the easiest way to find bolt thread size?

The easiest method is using a dedicated bolt size finder tool. These inexpensive tools quickly identify both diameter and thread pitch without guesswork.

Can I use a bolt that's slightly different in size?

Generally, no. Even small size differences can compromise the strength and safety of a connection. Always use the exact size specified for your application.

How do I find the nut size for the bolt?

The nut size corresponds to the bolt size. If you know the bolt diameter and thread pitch, you can find a matching nut. Alternatively, test the bolt with various nuts until you find one that threads on smoothly without force.

Why does thread pitch matter?

Thread pitch determines how many threads engage per unit of length. The wrong pitch can cause cross-threading, stripped threads, or improper clamping force, all of which can lead to joint failure.

What's the difference between a bolt and a screw?

Bolts typically require a nut to fasten materials together, while screws thread directly into a pre-tapped hole or material. However, the terms are often used interchangeably in casual conversation.

How do I find the wrench size for the bolt?

The wrench size corresponds to the bolt head size, not the thread diameter. Measure across the flats of the bolt head to determine the correct wrench or socket size.