Table of Contents

- Introduction: Why Pocket Screws?

- Tools & Materials You’ll Need

- Step-by-Step Guide: How to Use Pocket Screws

- Common Applications of Pocket Screws

- Tips & Mistakes to Avoid

- Advantages of Pocket Screws

- Pocket Screws vs. Other Joinery Methods

- DIY Project Ideas with Pocket Screws

- Frequently Asked Questions (FAQ)

- Conclusion

Introduction: Why Pocket Screws?

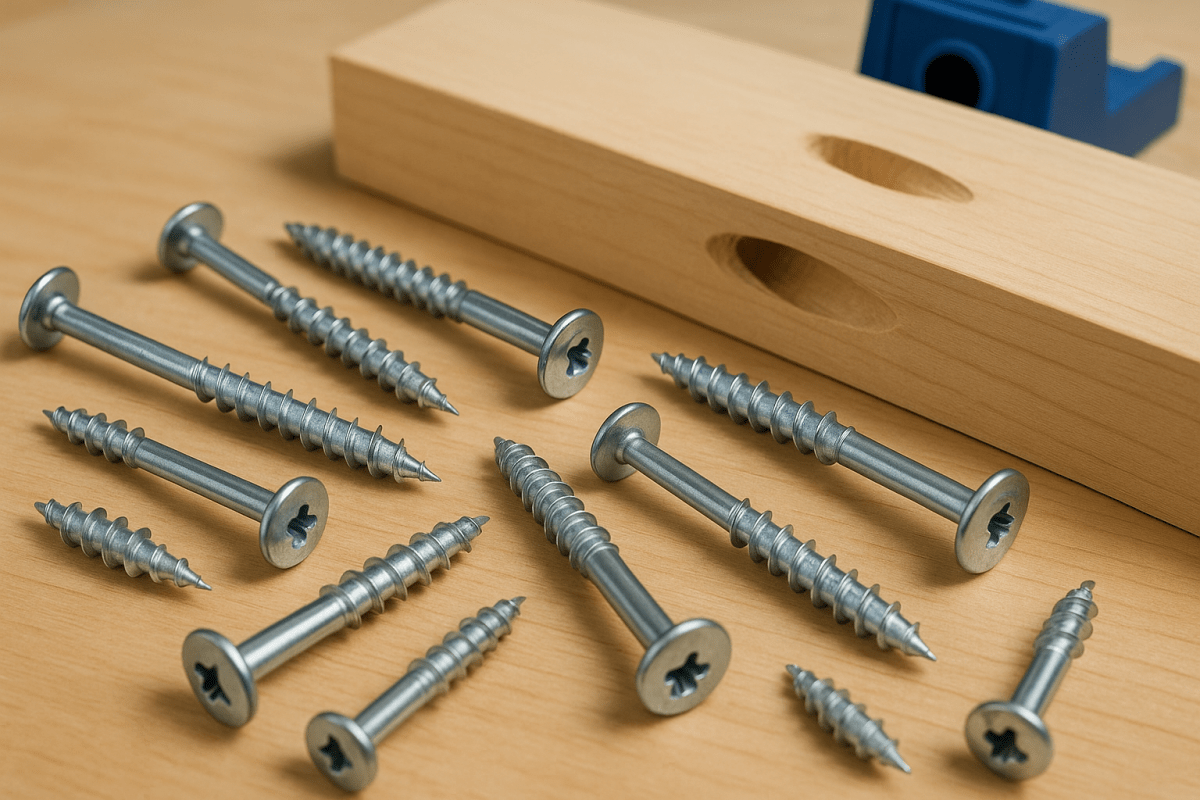

Ask any seasoned woodworker about the most versatile fastener in their workshop, and they’ll likely mention pocket screws. These clever screws allow you to create strong, hidden joints quickly and without advanced joinery skills. They’re perfect for building furniture, cabinetry, frames, and almost any wood-based project. Instead of spending hours cutting dovetails or mortise-and-tenon joints, pocket screws let you achieve durable results with just a drill and jig.

Tools & Materials You’ll Need

Before we dive into the step-by-step process, let’s make sure you have the right setup. To use pocket screws, you’ll need:

- Pocket hole jig

- Drill/driver

- Special pocket hole drill bit (usually included with the jig)

- Clamp to hold pieces steady

- Pocket screws (different sizes depending on wood thickness)

- Wood glue (optional for added strength)

- Safety gear (goggles, hearing protection)

Step-by-Step Guide: How to Use Pocket Screws

Let’s break down the process so even beginners can follow along.

Step 1: Set Up Your Jig

Adjust your pocket hole jig based on the thickness of the wood. Most jigs have guides for ½", ¾", and 1½" stock. The drill bit depth collar should also be adjusted accordingly.

Step 2: Drill Pocket Holes

Clamp the jig securely to your wood and use the pocket hole drill bit to create angled holes. These holes guide the screw into the adjoining piece at just the right angle for strength.

Step 3: Align the Pieces

Position the wood pieces together as you want them joined. Use clamps to hold them steady—this prevents shifting when driving screws.

Step 4: Drive the Pocket Screws

Using a drill/driver and the special square-drive bit, insert your pocket screws into the holes until the joint is tight. Do not overtighten, as that can strip the hole or crack the wood.

Step 5: Finishing Touches

If desired, you can plug the pocket holes with wood plugs or filler to hide them completely. Sand and paint or stain as usual.

Common Applications of Pocket Screws

- Cabinet face frames

- Bookshelves

- Tables and chairs

- Picture frames

- Wooden storage boxes

- Repairing broken joints in furniture

Pocket Screws: Tips & Mistakes to Avoid

- Always use the correct screw length for the material thickness.

- Use coarse-thread screws for softwoods, fine-thread for hardwoods.

- Clamp tightly before driving screws to prevent shifting.

- Don’t skip adjusting your jig—wrong depth leads to weak joints.

- Consider glue for projects that need extra durability.

Advantages of Pocket Screws

Compared to traditional joinery, pocket screws offer speed, simplicity, and hidden strength. They allow you to assemble projects in minutes, not hours. Plus, the joints are secure without visible screws on the outside, giving a clean, professional look.

Pocket Screws vs. Other Joinery Methods

While dovetails and mortise-and-tenon joints are beautiful and traditional, they require skill and time. Pocket screws, on the other hand, deliver functional strength with minimal tools. Biscuits and dowels are alternatives but require more alignment precision. For beginners and pros alike, pocket screws strike the perfect balance.

DIY Project Ideas with Pocket Screws

- Build a farmhouse dining table

- Create custom bookshelves

- Assemble garage storage cabinets

- DIY bed frames

- Outdoor benches (with weather-resistant pocket screws)

Frequently Asked Questions (Pocket Screws)

1. Are pocket screws strong enough for furniture?

Yes! When used properly with the right length and thread type, pocket screws can easily hold furniture together for years.

2. Do I need glue with pocket screws?

Not always, but adding glue increases joint strength, especially on load-bearing furniture.

3. Can pocket screws be used outdoors?

Yes, but only with weather-resistant screws like our exterior pocket screws designed to resist rust and corrosion.

4. What’s the difference between coarse and fine-thread pocket screws?

Coarse-thread is best for softwoods like pine, while fine-thread works better for hardwoods like oak or maple.

5. Do pocket screws replace traditional joinery?

Not entirely. They’re a faster, easier option, but some traditional joints are still preferred for high-end craftsmanship.

Conclusion

Pocket screws are a game-changer for anyone working with wood. Whether you’re building a bookshelf, repairing old furniture, or tackling a custom DIY project, these screws make the job faster and easier while maintaining strength. With the right tools and a little practice, you’ll be amazed at what you can create. Start your next project today with pocket screws that are built to last.