Table of Contents

What Exactly Is a Window Seal?

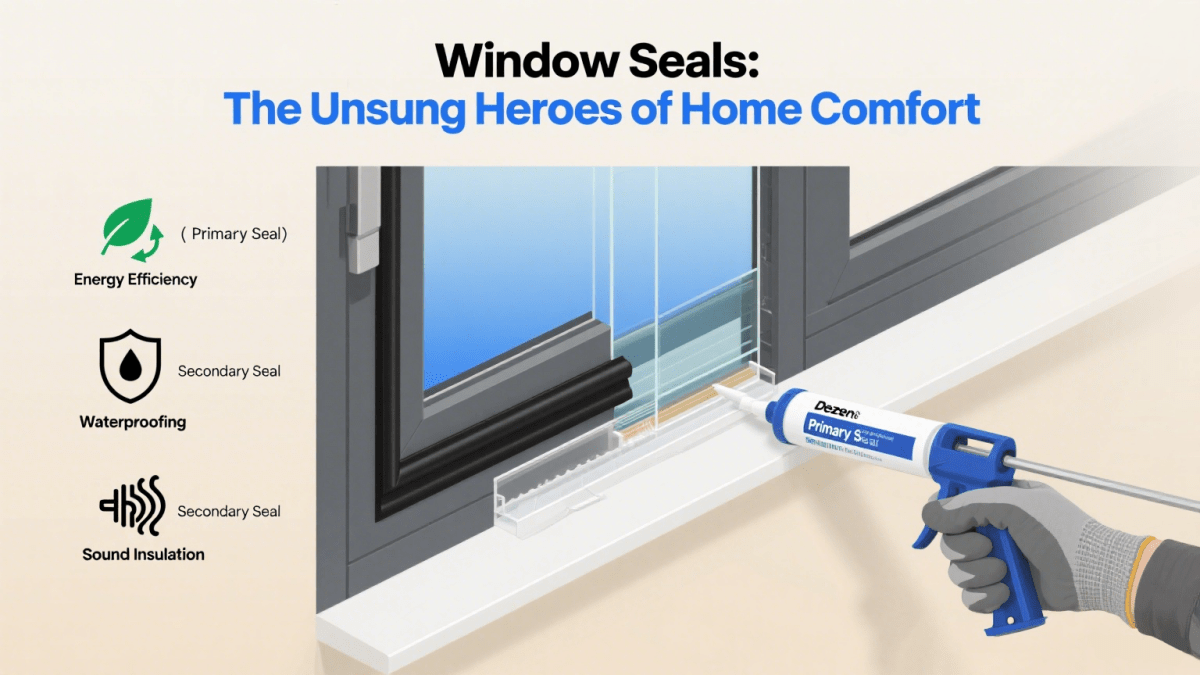

A window seal is a crucial component of your home's building envelope that creates an airtight and watertight barrier around windows. As a home improvement specialist who's helped hundreds of homeowners improve their energy efficiency, I've seen how proper sealing transforms comfort and utility bills. Essentially, a window seal prevents the elements from entering your home while keeping conditioned air inside.

Last winter, I helped a family in Minnesota reduce their heating bill by 23% simply by replacing deteriorated window seals. Their home had been losing heated air through tiny gaps they couldn't even see. After installing our high-performance window seals, they noticed immediate improvements in comfort and energy savings.

Window seals consist of three main components:

- Weatherstripping: A Flexible material that seals movable parts

- Caulking: A Sealant that fills stationary gaps

- Gaskets: Pre-formed seals for specific applications

Types of Window Seals: Understanding Your Options

Not all window seals are created equal. Different window types and applications require specific sealing solutions:

Compression Seals

Expand when compressed to fill gaps. Ideal for double-hung and sliding windows. Our compression seal collection features various densities to accommodate different gap sizes.

V-Strip Seals

V-shaped design that flexes to seal gaps. Perfect for sash channels and meeting rails.

Foam Tape

Self-adhesive foam that compresses to seal irregular surfaces. Great for stationary applications.

Magnetic Seals

Contains magnetic elements for perfect alignment on metal frames and doors.

Silicone Bulb Seals

Flexible silicone tubes with mounting bases. Excellent for high-temperature applications.

Interlocking Seals

A Two-part system that creates a mechanical lock. Maximum protection for extreme climates.

Window Seal Materials Compared

The material determines performance, durability, and appropriate applications:

| Material | Best For | Lifespan | Temperature Range |

|---|---|---|---|

| Vinyl | General-purpose, budget-friendly | 5-10 years | -20°F to 160°F |

| Silicone | High heat, flexible applications | 10-20 years | -40°F to 400°F |

| EPDM Rubber | Weather resistance, UV protection | 10-15 years | -40°F to 300°F |

| Neoprene | Oil resistance, industrial use | 7-12 years | -20°F to 200°F |

| Closed-Cell Foam | Irregular surfaces, soundproofing | 5-8 years | -20°F to 180°F |

| Thermoplastic | Precision applications, durability | 15-25 years | -40°F to 220°F |

For most residential applications, I recommend EPDM or silicone seals from our premium seal collection. These materials offer the best balance of weather resistance, flexibility, and longevity.

Primary Functions & Benefits of Window Seals

Quality window seals provide multiple benefits beyond simple weather protection:

Energy Efficiency

Prevents conditioned air escape, reducing HVAC costs by 10-20%

Water Protection

Creates a watertight barrier, preventing leaks and moisture damage

Noise Reduction

Absorbs sound waves, reducing external noise by up to 70%

Draft Elimination

Stops uncomfortable drafts that create cold spots

Insect Barrier

Blocks entry points for pests and insects

Dust & Pollen Prevention

Reduces indoor allergens by sealing out particulates

I recently helped a homeowner in Seattle address chronic mold issues caused by window leaks. By installing our heavy-duty window seals, we not only stopped the moisture intrusion but also reduced their heating costs and street noise.

Signs of Window Seal Failure

Recognizing failing seals early prevents costly damage. Look for these warning signs:

- Drafts: Feel for air movement around windows

- Condensation: Fogging between double-pane glass indicates failed IG seals

- Higher Bills: Unexplained increases in heating/cooling costs

- Visible Damage: Cracking, peeling, or compression set

- Water Stains: Discoloration on walls or sills below windows

- Noise Increase: More external noise penetration

- Difficulty Operating: Windows are hard to open/close due to seal friction

Climate-Specific Sealing Solutions

Different climates demand different sealing approaches:

| Climate Type | Recommended Seal | Special Considerations |

|---|---|---|

| Cold Northern | Compression seals with high recovery | Focus on thermal protection, avoid moisture trapping |

| Hot Southern | UV-resistant EPDM or silicone | Prioritize UV protection and heat resistance |

| Coastal/Humid | Closed-cell foam or marine-grade silicone | Resistance to salt air and high humidity |

| Dry/Arid | Dust-proof interlocking seals | Prevention of fine dust infiltration |

| Variable/Mixed | Multi-season compression seals | Flexibility to handle temperature swings |

For homeowners in extreme climates, our climate-specific seal collections take the guesswork out of selection with products engineered for particular environmental challenges.

Professional Installation Tips for Perfect Sealing

Proper installation ensures maximum performance and longevity:

Preparation Steps:

- Clean surfaces thoroughly with isopropyl alcohol

- Remove old sealant completely

- Measure gaps accurately - seals should compress 25-40%

- Cut seals at 45° angles for corners

- Test fit before final installation

Installation Techniques:

- Compression Seals: Install at room temperature, don't overstretch

- Self-Adhesive Seals: Apply pressure for 30 seconds after placement

- Silicone Caulking: Use masking tape for clean lines, tool with a wet finger

- V-Strip Seals: Install with V opening toward interior

DIY vs Professional Seal Replacement

Understanding when to DIY and when to call a pro saves time and money:

DIY-Friendly Projects

- Weatherstripping replacement

- Caulking stationary gaps

- Applying foam tape seals

- Simple compression seals

Call a Professional

- Insulated glass unit seal replacement

- Structural sealing issues

- Historical window preservation

- Complex interlocking systems

Most homeowners can handle basic weatherstripping with our DIY seal kits, which include detailed instructions and all necessary tools. For complex jobs, the investment in professional installation pays off in long-term performance.

Energy Efficiency Impact: The Numbers

Proper window sealing delivers significant energy savings:

| Sealing Improvement | Energy Savings | Payback Period | CO2 Reduction |

|---|---|---|---|

| Basic weatherstripping | 5-10% | 1-2 years | 500-1,000 lbs/year |

| Complete resealing | 10-20% | 2-4 years | 1,000-2,000 lbs/year |

| Premium sealing system | 15-25% | 3-5 years | 1,500-2,500 lbs/year |

These numbers are based on average US energy costs. In extreme climates, savings can be even higher. I helped a client in Chicago reduce their annual heating bill by $380 simply by upgrading their window seals before winter.

Maintenance & Care for Long-Lasting Seals

Proper maintenance extends seal life by years:

Regular Maintenance:

- Clean seals quarterly with mild soap and water

- Inspect annually for cracks, compression set, or damage

- Lubricate moving seals with silicone spray (not petroleum-based)

- Keep drainage channels clear of debris

Seasonal Checks:

- Spring: Check for winter damage, clean thoroughly

- Fall: Prepare for winter, ensure proper sealing

- After extreme weather: Inspect for damage

Frequently Asked Questions

How long do window seals last?

Quality window seals typically last 5-15 years, depending on material, climate, and maintenance. Premium silicone and EPDM seals can last up to 20 years with proper care.

Can I seal windows from the inside only?

For maximum effectiveness, seal both inside and outside. Interior sealing stops drafts, while exterior sealing prevents water intrusion. Our complete sealing kits include materials for both applications.

Are expensive window seals worth it?

Higher-quality seals offer better longevity, performance, and often pay for themselves through energy savings. For permanent homes, investing in premium seals is typically worthwhile.

How do I measure for replacement seals?

Measure the gap width, depth, and length. For compression seals, choose a size that will compress 25-40% when installed. Our measurement guide provides detailed instructions.

Can window seals reduce noise?

Yes, quality seals can reduce noise transmission by 60-70%. For maximum soundproofing, combine seals with acoustic caulk and secondary glazing.

Sealing Your Home's Comfort and Efficiency

Understanding window seals transforms how you maintain your home. As we've explored, these unassuming components play a crucial role in:

- Energy efficiency and utility savings

- Indoor comfort and temperature consistency

- Moisture protection and prevention of structural damage

- Noise reduction and peaceful living environments

- Overall home durability and value preservation

At Home DIYer, we've curated the most comprehensive window seal collection for American homeowners. From basic weatherstripping to premium climate-specific systems, our products help you achieve professional results without professional costs. Don't let invisible gaps compromise your comfort - upgrade your seals today and start enjoying a better-sealed home tomorrow!