Table of Contents

- What Exactly Is a Rubber Stopper?

- A Brief History of Rubber Stoppers

- Rubber Stopper Materials Explained

- 7 Essential Types of Rubber Stoppers

- Plumbing & Pipe Applications

- Electrical Safety Uses

- Automotive Solutions

- Home & DIY Projects

- Industrial Applications

- Choosing the Right Rubber Stopper

- Installation Mastery

- Creative Uses Beyond Basics

- Frequently Asked Questions

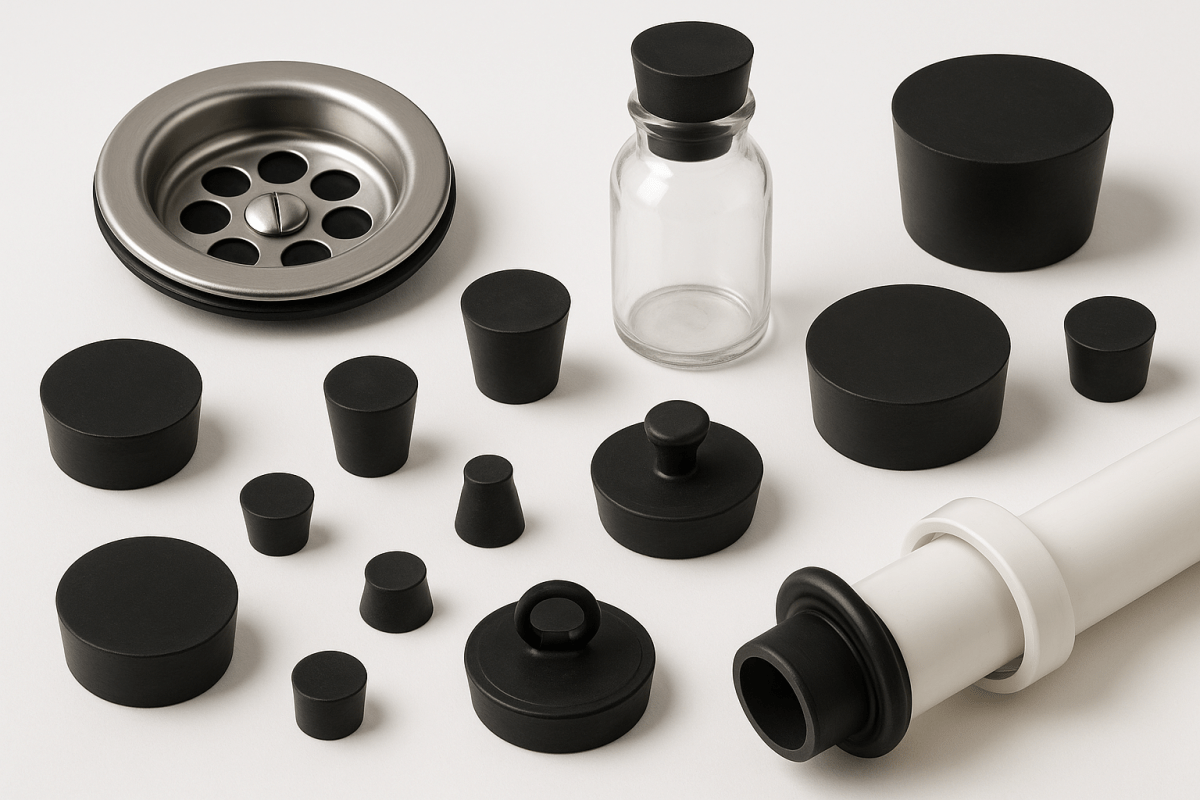

What Exactly Is a Rubber Stopper?

A rubber stopper (often called a rubber plug) is a precisely engineered sealing device designed to close openings in pipes, containers, and equipment. Unlike rigid caps, these flexible components create compression seals that adapt to surface imperfections and temperature changes. At its core, a rubber stopper solves a simple but critical problem: keeping things in and keeping things out.

During my 15 years in hardware retail, I've seen how these unassuming components prevent thousands of dollars in damage. Just last month, a customer avoided basement flooding by using a $3 EPDM rubber plug to seal a broken pipe until repairs could be made. That's the power of proper sealing!

A Brief History of Rubber Stoppers

The story begins in 1839, when Charles Goodyear revolutionized materials science through the process of vulcanization. This process transformed natural rubber from a temperature-sensitive material into a durable, elastic compound perfect for sealing applications. Early rubber stoppers first appeared in laboratories and industrial settings, but it wasn't until the DIY boom of the 1950s that they became a household essential.

Modern rubber stoppers have evolved dramatically with advanced polymers. Today's versions withstand extreme temperatures, chemicals, and pressures unimaginable to early manufacturers. Our specialty plugs collection includes FDA-grade silicone for food applications and conductive rubber for EMI shielding - lightyears beyond Goodyear's original vision!

Rubber Stopper Materials Explained

Not all rubber stoppers are created equal. The material determines performance:

| Material | Best For | Temperature Range | Lifespan |

|---|---|---|---|

| EPDM Rubber | Plumbing, outdoor use | -40°F to 300°F | 10+ years |

| Silicone | Food applications, high heat | -60°F to 450°F | 15+ years |

| Neoprene | Oil resistance, automotive | -20°F to 200°F | 5-8 years |

| Natural Rubber | General-purpose sealing | 0°F to 160°F | 3-5 years |

| Nitrile | Fuel systems, chemicals | -30°F to 250°F | 7-10 years |

7 Essential Types of Rubber Stoppers

Tapered Plugs

The conical shape creates increasing pressure as inserted. Perfect for irregular openings. Our tapered plug set handles 90% of DIY needs.

Flanged Stoppers

A Wider lip prevents push-through. Essential for pressurized systems and child safety applications.

Threaded Plugs

Combine rubber sealing with threaded security. Ideal for vibration-prone locations like vehicles.

Hollow Core Plugs

Allow cable/wire passage while maintaining the seal. Crucial for electrical and data applications.

Pull-Ring Stoppers

Integrated removal tab for easy extraction. Lifesavers for deep-set installations.

Magnetic Plugs

Embedded magnets for tool retention. Popular in manufacturing and automotive shops.

Vented Plugs

Allow pressure equalization while blocking contaminants. Perfect for gear cases and electronics.

Plumbing & Pipe Applications

Rubber stoppers are plumbing essentials. I recommend every homeowner keep our plumber's plug kit for emergencies:

- Freeze Protection: Seal outdoor faucets before winter

- Reno Safety: Prevent sewer gas entry during remodels

- Leak Control: Emergency seal for burst pipes

- Pressure Testing: Isolate sections during diagnostics

- Thread Protection: Guard pipes during storage

Last winter, a client avoided $8,000 in water damage by using a heavy-duty rubber plug on a cracked sprinkler line until spring thaw. The secret? EPDM material that stayed flexible at -15°F.

Electrical Safety Uses

Rubber stoppers prevent electrical hazards by:

- Sealing unused knockouts in breaker panels

- Protecting outdoor receptacles from moisture

- Child-proofing exposed junction boxes

- Insulating live terminal connections

- Preventing dust buildup in sensitive electronics

For electrical applications, always use plugs rated for dielectric strength. Our electrical-grade plugs meet UL 94V-0 flame resistance standards.

Automotive Solutions

Under every vehicle, rubber stoppers fight corrosion and contamination:

- Frame rail drain hole protection

- Engine bay opening seals

- Fluid reservoir test port covers

- Sensor connector dust barriers

- Body panel hole plugs

I recently helped a classic car owner restore a '67 Mustang. We used our automotive plug set to replace 23 deteriorated factory plugs, preventing future rust damage.

Home & DIY Projects

Beyond repairs, rubber stoppers enable creative solutions:

- Convert containers into airtight storage

- Create non-slip furniture feet

- Make custom grommets for wiring

- Seal ends of DIY handrails

- Plug holes in outdoor furniture

- Craft vibration-dampening mounts

One customer even used tapered plugs as temporary kayak repairs after river rock impacts! For most DIY applications, our assorted plug kit offers the best versatility.

Industrial Applications

In manufacturing, rubber stoppers perform critical functions:

- Seal chemical process vessels

- Protect precision machining threads

- Isolate hydraulic test ports

- Create sterile barriers in pharma

- Prevent contamination in food processing

Conductive rubber stoppers are particularly valuable in electronics manufacturing, where they provide EMI shielding while sealing enclosures.

Choosing the Right Rubber Stopper

Follow this decision framework:

- Measure precisely: Determine both hole ID and depth

- Identify contaminants: Chemicals? UV? Oils?

- Consider temperature: Will it freeze or overheat?

- Evaluate pressure: Vacuum or positive pressure?

- Determine access: Need easy removal? Add a pull ring

When in doubt, EPDM offers the best all-around performance for North American climates. Explore our material selection guide for specific applications.

Installation Mastery

Proper technique ensures perfect seals:

- Clean surfaces with isopropyl alcohol

- Lubricate with water or silicone spray

- Insert at a 45° angle, then straighten

- Check compression - 30% deformation is ideal

- Test seals with water or a soap solution

Creative Uses Beyond Basics

Rubber stoppers solve unexpected problems:

- Gardening: Create self-watering planters

- Aquariums: Seal unused filter ports

- Music: Mute drums or dampen vibrations

- Boating: Emergency hull patch

- Crafting: Make custom stamps

- Organization: Cap Sharp Tools in storage

One artist even uses colored plugs as design elements in kinetic sculptures! With our specialty plugs collection, your creativity is the only limit.

Frequently Asked Questions

Are rubber plugs and rubber stoppers the same thing?

Yes, the terms are interchangeable. Both refer to flexible sealing devices designed to close openings.

Can I use rubber stoppers for drinking water?

Only NSF-certified materials like FDA silicone or EPDM are safe for potable water systems.

How do I measure for the right size rubber plug?

Measure the inner diameter (ID) of the hole and depth. Our sizing guide helps match measurements to products.

Why did my rubber stopper crack and fail?

Common causes: ozone exposure (EPDM resists this), petroleum contact (use neoprene), extreme cold (silicone performs best), or UV degradation.

Can rubber stoppers withstand pressure?

High-quality plugs like our industrial series handle up to 150 PSI when properly installed.

The Humble Hero of Hardware

From preventing basement floods to protecting your car's frame, rubber stoppers solve problems you didn't know you had. As we've explored, these versatile components deserve a permanent spot in every DIYer's toolkit. Whether you're tackling plumbing emergencies, electrical projects, or creative endeavors, the right rubber plug can mean the difference between success and disaster.

At Home DIYer, we stock over 92 sizes and materials specifically chosen for North American homeowners. Explore our rubber plug collection to find your perfect sealing solution. Got a unique challenge? Our hardware specialists are ready to help at support@homediyer.com!